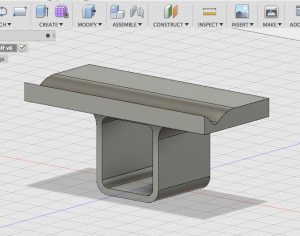

This past week, Dan Banach, a representative from Autodesk led a hands-on workshop on how to design in Autodesk’s Fusion 360 software. Fusion 360 is a powerful tool that allows individuals to model out their ideas. Models can be shared digitally or designed with the intent to be physically produced. Although I was not able to attend this past week’s session in-person I was able to connect with some of my peers to review what I missed from Dan’s workshop.

Completing the fusion 360 tutorial really helped me gain a better understanding of how to use the software. I was able to first-hand experience the various nuances of the software and functionalities. For me, there was a big learning curve to learn the software because I do not have very many technical skills. This was a nice way to learn another technical skills and reinforced how beneficial it is to have software knowledge.

Here’s what I learned:

I learned to take my time and understand what I was doing. From connecting with my peers who sat in on the workshop and completing the Fusion 360 Youtube tutorial, I learned that it was more important to understand why I was doing what I was doing and its role in creating the end product. Additionally, the step by step instructions made it extremely easy to follow along and it also strengthened my understanding of the Fusion 360 design process. The neat part about learning from others and engaging in self-learning through instructional videos was that it compelled me to learn something new. By collaborating with my peers, and utilizing broad resources available on the internet, I have been able to develop a new technical skill.

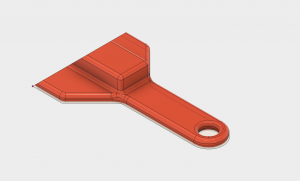

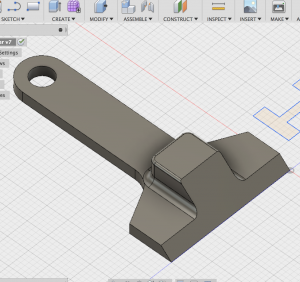

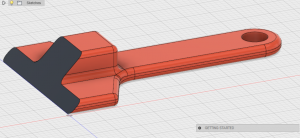

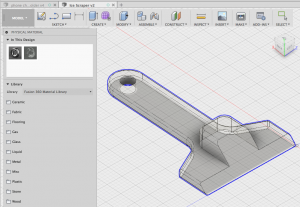

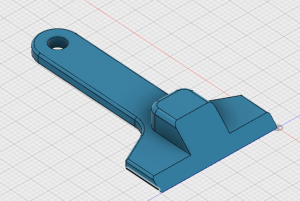

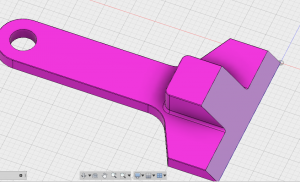

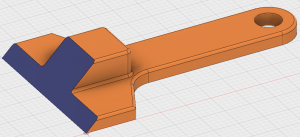

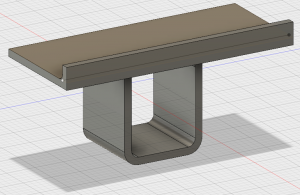

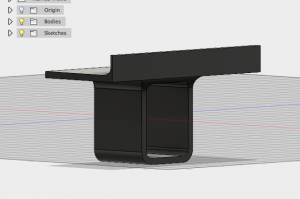

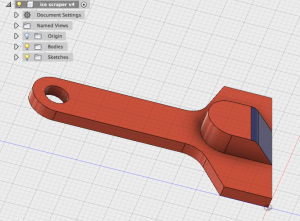

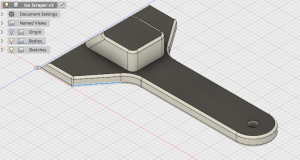

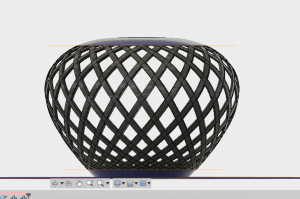

Although I was unable to attend the session in-person, I was still able to learn how to create the ice scraper. It was difficult to piece everything together, but below is what my design ended up looking like.

http://a360.co/2BUCb8b

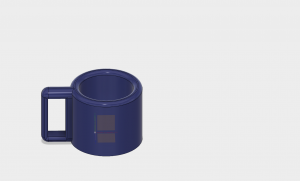

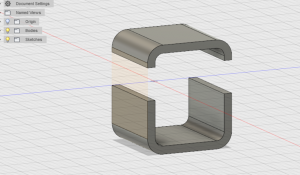

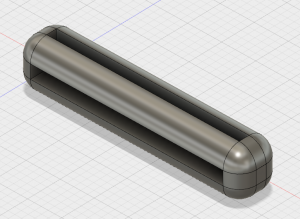

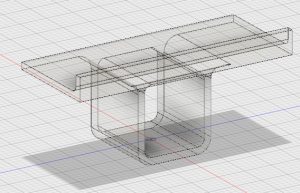

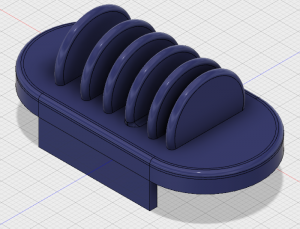

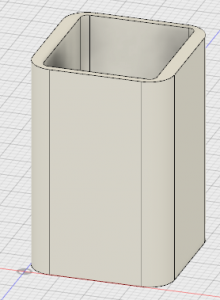

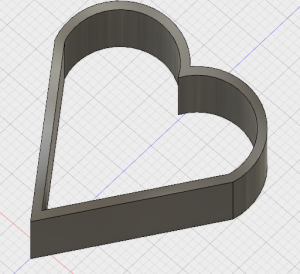

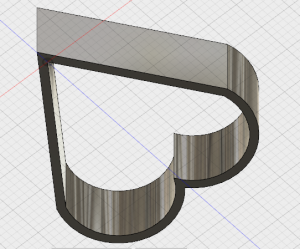

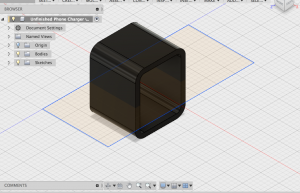

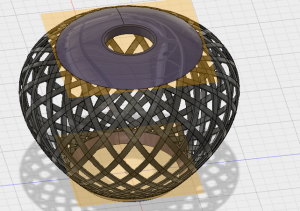

This week, I watched a tutorial and learned how to build a lampshade. It was exciting to see that I have now developed a base-line understanding of Fusion 360. Although the directions and terminology used in the instructional video I watched differed from another one I saw, I was still able to follow along. The design I created can be found in the link below.

http://a360.co/2Bnu3Mp