This week I went to the Fab Lab that we have on campus. I never realized that this place existed, but I am so very glad that I now know of it. I plan to visit it later this week to create customized stickers for an organization that I am a part of! The FabLab is opened to the public and is a space that encourages people to be makers and try out different techniques and processes. With the wide range of tools being offered, I worked with the universal laser system X-600.

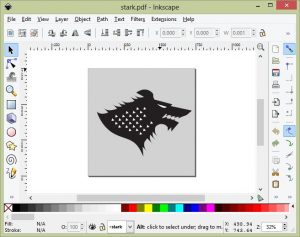

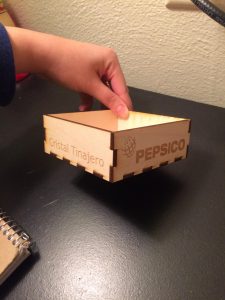

The goal was to make a customized wooden box that would use the system mentioned above. But, first I needed to create and design the different parts of the box on a software known as Inkscape which is a free and open-source vector graphics editor similar to Adobe Illustrator. As any new software, it took some time getting used to it, but it wasn’t too difficult! For my box, I wanted it to capture the highlights of my senior year. I also wanted to test how well the laser would would construct the details of a digital photo image that I took. I included that image on the bottom of the box for safe measures. Next, I needed to transfer the design to the laser system software, select my material as well as brighten the digital photo for better quality. I placed the ply wood into the system and then began the laser process. I was really impressed by how the final product came out and I am pleased with the overall quality of the shadow box.

One thing that I did noticed when the plywood was being lasered, was the small fire that emerged from time to time. I wondered if this was problematic with the system or if it is considered to be hazardous. I found out that laser safety standards are well established and relatively harmonized internationally. And that those standards establish four broad classifications of laser safety for products. The classifications range from Class 1, in which the laser energy is fully contained within the laser system and the operator is not exposed to any laser energy, to Class 4, in which the laser system does not have containment provisions and the operator can potentially be exposed to high levels of laser energy.

Final Project

Ultimately, we have decided that for our final project we would like to incorporate 3D printing into window farms. We would like to create a window farm that uses various sensors and a micro-controller to sense its environment and adapt accordingly. After doing some more research, we would like to work with vertical hydroponic gardening systems. These plants do not use soil to grow but rather use mineral solution nutrients. I am very exciting for our project and I am looking forward of the development of it.

That concludes my blog for this week,

Thanks for reading!