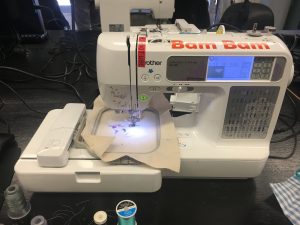

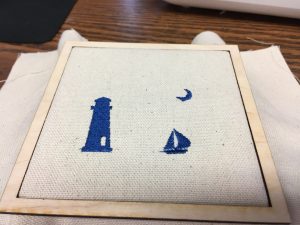

This week, I was able to finish my embroidery at the FabLab. It was recommended that I select an image with not many colors. I went with a classic rose and I also included a customized design with my initials on the lower right hand corner.

The final product came out better than I could have expected! The design did come out smaller then anticipated and at times, the machine would pucker. In order to prevent puckering, click on the link to watch a shot video for what to do! https://www.youtube.com/watch?v=EA-90RzIGhs

Putting it all together

Now that the laser-cut wooden box and embroidery were completed, it was time to add some lights to it! This was the portion that I imagined would be the most difficult, but with great instructors and my skillsets growing, it wasn’t too bad! We were given a battery, an LED light, and a controller switch.

With these three objects and some conductive thread, you make light! But, it is very important that crossing wires are not different charges (+/-). This can become a issue with additional lights being added, I just had one so I didn’t have to worry about that. I placed my light behind the flower to create a glow and have a Beauty and the Beast effect.

The part that I enjoyed the most out of this project was the stitching. I have never stitched before, so it took some time getting used to. I was a little worried about poking myself, but I came out without a scratch! This is a skillset that will come in handy someday.

Thank you for reading!