Overview

Our class was spoiled this week with having two very influential people speak to our class. Our first speaker, Alan Amling, taught us about the advancements that UPS is making in the realm of 3D printing. Our second speaker, Dot Silverman, taught us about her work in biohacking and the exciting projects she is working on. During the second half of the class, we were able to meet with our teams to begin narrowing down our ideas for the semester project.

What is UPS Doing?

Alan informed us that UPS is taking major strides in utilizing 3D printing. The company has facilities that are capable of 3D printing on both the small and large scale. Alan mentioned that UPS’s Louisville, KY facility center can print something out by midnight and then be anywhere in the United States the next day. Such a capability is revolutionary for any company. Currently, it is common for consumers to have to wait multiple days before receiving an item they purchase. However, as more and more 3D printing facilities pop up throughout the country, it will be much more likely that future consumers can order custom 3D-printed products and expect to receive them the same day (maybe even within hours).

One of my biggest takeaways from Alan is the importance of consistency. It’s incredible that 3D printers can create almost anything, but Alan noted that if a company wants to be successful, then they will need to be consistent. For instance, many current manufacturing processes are standardized and effective enough to produce identical objects on a large scale. Since 3D printing technology is still relatively new, there are still areas in which errors are made (thus reducing consistency). Moving forward, I will remain conscious of these potential limitations of 3D printers, and I hope to play a part in identifying ways in which consistency can more likely be achieved at the industrial scale.

What is Biohacking?

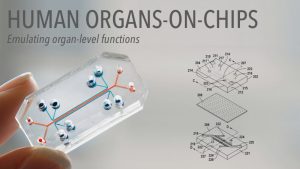

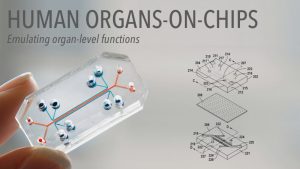

Dot shared a bunch of exciting projects with our class in the realm of biohacking, which essentially is combining biology with making/3D-printing. One of Dot’s projects that stood out to me was one in which she had previously worked on a team that created human organs-on-chips; these chips emulate organ-level functions. What was really neat was that Dot and her team were able to combine a bunch of different organs-on-chips and connect them to simulate an actual human body. They then were able to simulate cocaine entering the body and the implications that it had on each organ. These devices (pictured below) may be a great alternative to animal-testing (which remains to be controversial among many consumers). Ultimately, these creations are extremely exciting and could lead to incredible breakthroughs in the medical industry.

Progress on Final Project

My group and I have narrowed down our list of final project ideas. Two of the ideas that I feel most passionate about are the creation of assistive devices for individuals with disabilities and a Neopixel Traffic Map. The types of assistive devices we are looking into are for individuals with limited motor-movements. For instance, individuals with arthritis may no longer be able to hold a pen like they used to. Such a disability can be devastating to many people as they may find joy in sending handwritten notes to their friends and family. 3D printing objects are able to extend an individual’s motor capabilities and increase precision. It would be neat for my group to talk with individuals who have arthritis/limited motor capabilities to understand what challenges they face most often in order to develop an all-in-one tool to help them navigate through their days more easily (see an example in the picture below). Another assistive device that we may look into printing would be wheelchairs, and you can learn more about this idea’s potential through one of my previous blog posts by clicking here.

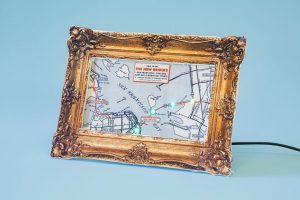

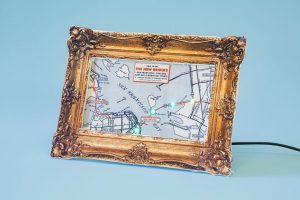

The second idea that I find interesting is a Neopixel Traffic map (example pictured below). Essentially, we would be creating a way for a user to know the traffic conditions of a certain area before leaving their home/work. This would be accomplished through inserting LED lights into a picture map and connecting them to an Arduino board that would relay real-time traffic conditions via a paired Google Maps API (Application Program Interface). This project would involve us learning to code, working with API’s, and utilizing circuit boards–and we know we are up to the test!

Thank you

Thank you for taking the time to read my blog post. As mentioned, my team is finalizing our idea for our semester project, and I can’t wait to share with you what we end up deciding to pursue!

-Scott Provenzano

References

https://3dprint.com/85424/3d-printed-assistive-devices/

https://makezine.com/projects/arduino-neopixel-traffic-map/

https://publish.illinois.edu/digitalmaking2018/2018/02/14/3d-printing-wheelchairs-assistive-devices/