Background

3D printing has an infinite amount of potential to improve our world and the lives of humans. An area of improvement that I am passionate about is in the realm of improving the lives of individuals with disabilities.

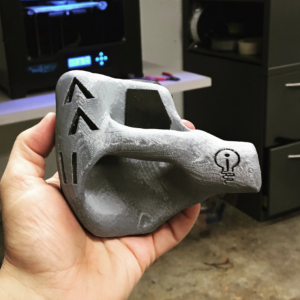

On January 17th, 2018, our Digital Making Seminar class had the distinct pleasure of hearing Arielle Rausin speak on her experience in 3D printing. Arielle has since pursued a career in 3D printing by manufacturing racing gloves for wheelchair racing athletes (see picture below). Her company is called Ingenium, and you can check out the website here: http://www.ingeniummanufacturing.com/.

Arielle was kind enough to chat with me on the phone and allow me to ask her questions. During this time we talked about 3D printing and the opportunities/challenges that Arielle has come across throughout her time in this field. Below I have the questions that I asked Arielle along with her (paraphrased) responses.

Interview with Arielle Rausin

Q1: How are you doing? As a person? As a student? As a CEO?

A1: Pretty good. Busy busy life–I like keeping busy. It takes a lot of balance between being a full-time athlete and running a company. I graduated in December, so I am no longer a student. Right now I work part time on campus and train full-time as an athlete.

Q2: Can you talk a bit about the challenges that you faced when first starting to 3D print the gloves?

A2: First was becoming familiar with the software and learning how to do things like manipulate the infill, correct sizing (what you need to scale) and what you need to go in an adjust by hand. Once I bought a 3D printer, it was tough learning the printer maintenance (which needs to be every few months or so), printer clogs, etc. Another challenge is learning to design the file to make sure you are reducing the risk of clogging. Such designs need to be implemented in every file; a lot of the software does that automatically and it keeps improving every year. Additionally, I had to learn how to train my employees in the software.

Q3: Has your company made any progress or performed research in the realm of 3D printing wheelchairs? Are you aware if anyone has successfully done this?

A3: Personally, I have done a decent amount of research. I have not been able to find anyone who has been able to successfully accomplish it. There’s a company in South America that has done pieces of chair, but it wasn’t able to support any weight. I thinks it hasn’t been accomplished because of a lack of people trying rather than it being impossible. I have talked with wheelchair manufacturers that currently weld wheelchairs (traditional form of manufacturing), and I asked if they were interested in 3D printing–most are not interested. An additional note: there is a group in India that is starting to 3D print posture alignments that would attach onto wheelchairs (essentially a wheelchair accessory).

Q4: Follow up question: why do you think the manufacturers that you have reached out to weren’t interested?

A4: I believe it is due to the high upfront cost of learning the new technology and buying the printers. Most of the companies that make wheelchairs in the US have been around for 20-30 years, so the cost of learning a new technology is a big barrier. Also, they are from a different generation. I found this extremely evident when I ordered my previous wheelchair. I actually had to fax in a form to the wheelchair company because they didn’t even have online capabilities. Again, it’s a generational difference.

Q5: What are the most prominent challenges you see with 3D printing wheelchairs?

A5: I’ve talked with my coach about this, and he notes that he is worried about durability. Especially in developing countries, there is a lack of paved roads and stable terrain–thus, the chairs need to be very durable. In a welded chair, you can weld it again to fix it. For a 3D printed wheelchair, it would not have much room to be able to break. That being said, it would be much better to use metal/steel 3D printers for creating wheelchairs because they would be more durable (yet also more expensive).

Q6: Are there any parts of a wheelchair that would not be able to be 3D printed? Do you think it would be too burdensome to use small printers to then piece the prints together (i.e. are larger printers necessary)?

A6: I see a few items that would not be able to be 3D printed. First, the tires would need to be rubber and thus manufactured; I am not sold on the durability of 3D printed wheels. Also, some of the hardware–like the screws–would not be printed. The cushion where the wheelchair user sits would also not be printed.

Q7: Are you familiar with any resources that would be helpful in beginning of production of printing wheelchair parts? For instance, what is the best way to find out each of the necessary components?

A7: To begin, it would be best to directly talk to wheelchair users and see which parts on their wheelchair break the most often. It’d be good to understand which parts need to be replaced most often because those parts could potentially be printed cheaply. A lot of wheelchair manufacturers make “folding frame” chairs, which are completely useless to everyday wheelchair users. The frames that you would want to look at are called “rigid frame” chairs because those are more useful to everyday users.

Q8: I took a course in college called “The Culture of Disability,” and it was one of the most beneficial/educational courses I have ever taken because I learned so much about disabilities in our society. As someone with a disability, what do you wish individuals without disabilities knew in regards to the culture of disability?

A8: I wish people without disabilities knew that people with disabilities are very very capable. As a wheelchair user, I don’t mind if people ask me if i need help. Like I am capable of getting out of my car by myself everyday. People need more faith in the ability of wheelchair users. I think people without disabilities should come to an understanding that we are athletes, travel the world, live independently, etc. It’s depressing when people are shocked that I can drive and live alone. I like the saying “Assume competence.”

Q9: What is your favorite part about your job?

A9: My favorite part is when I hear that it has positively impacted people’s performance. For instance, I like when I get emails and pictures from parents and coaches saying their athlete achieved one of their goals through using our products.

Q10: Do you have a 5, 10, or 20 year plan? If so, what does it look like?

A10: I believe in plans, but I know they can change really really quickly. Currently, I am training for the Tokyo 2020 Paralympics (2.5 year plan) in hopes to attend the games and compete. At the end of the day, I need to keep in mind that my athletic training is a full-time job. I would also love to help people with disabilities (by providing them with wheelchairs). I have been able to do this in the past by going to developing countries with non-profit organizations to distribute wheelchairs. In the next 5 years, I think it would be incredible if Ingenium could have fully working 3D-printed wheelchairs and a business model that would allow us to give them out for free.

Takeaways

I truly appreciated the time that Arielle took to chat with me about her experiences. My two biggest takeaways were in regards to the current wheelchair manufacturers’ generational differences and her advice to talk with current wheelchair users.

As for the generational differences with wheelchair manufacturers, I found Arielle’s insights fascinating. Initially, I thought that wheelchair manufacturers would love the idea of 3D printing due to the increased ability to customize their products at a cheaper cost. However, Arielle informed me that the upfront costs are what deter the manufacturers from fully adopting this practice. Since they have already invested so heavily in fixed costs over the past 20-30 years, they do not currently find much incentive for purchasing even more items that would qualify as fixed costs (i.e. 3D printers, training, and machinery). I find this to leave a tremendous area of opportunity to first-movers in the 3D printing realm for wheelchairs, which I will discuss in the “Moving Forward” section below.

As for talking with current wheelchair users, I find this advice very useful. As a creator, I often find myself wanting to delve right into the details of the product rather than first consulting with the end-users. I am thankful that Arielle gave me this advice because I will be able to save valuable time in the future by first understanding the needs of the end-users before I make assumptions of their needs and begin work on a product. This also ties into Arielle’s quote of “assuming competence.” People with disabilities are able to accomplish just as much as people without disabilities; those with disabilities may just have different ways in accomplishing those tasks. Thus, individuals with disabilities are competent in best understanding their needs, and creators must openly listen to those needs before creating.

Moving Forward

I know I threw a lot of information at you throughout this post, so I wanted to utilize this section to let you know some opportunities that you can explore to make tangible improvements in the realm of 3D printing for accessibility.

Our instructor, Vishal Sachdev, has shared a link with our class that talks about a company (called Allianz) that is trying to be the first-mover for the 3D printing of wheelchairs (https://www.3dprintingprogress.com/articles/13633/creating-the-future-of-wheelchairs-through-3d-printed-devices). Allianz is requesting innovators to submit ideas and designs for adaptive mobility devices, like wheelchairs. Personally, I believe that the current wheelchair manufacturers will need to convert to 3D printing once fully-functioning wheelchairs and other mobility devices are able to be dependably created by competitors using 3D printing. I believe this largely due to the lower costs that the 3D printing companies will encounter. These lower costs will thus allow the 3D printing companies to charge their customers less for the products and shift the demand away from the more expensive wheelchairs that are currently being manufactured. Contributing to the efforts of Allianz would be a great way to use your ideas and creating skills to innovate in the realm of 3D printing. Your contributions may also lead to lasting benefits for the community of individuals who require wheelchair use by providing more customized and affordable wheelchairs. Below is an image of a 3D-printed wheelchair concept.

Arielle also told me a bit about one of the non-profits she has worked with: Walkabout. With this company, she was able to go to Kenya last summer and give out wheelchairs to developing areas. She found the opportunity with this company through conducting her own online research and finding an organization that aligned with her values. Walkabout gives out over 10,000 wheelchairs a year, which is a noteworthy accomplishment since the company currently only has 5 full-time employees in London. Currently, Walkabout does not 3D print their parts, but that is great news because that leaves the opportunity open for creators like us to continue innovating in this realm. With our innovations, we can hopefully someday assist Walkabout in adopting 3D printing to then be able to provide even more wheelchairs individuals in need. This summer, Arielle will have the opportunity to go to Sudan with Walkabout. Please see the following link if you would like to explore future opportunities with this inspiring organization: https://walkaboutfoundation.org/

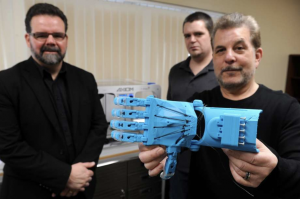

I’d also like to share the following link with you that has great examples on additional 3D printing designs that can be used for assisting those with disabilities: https://3dprint.com/tag/3d-printed-assistive-devices/. One of the designs on this site that I found interesting was of the prosthetic hand (see picture below). Prosthetic hands can sell for upwards of $11,000 (source: singularityhub.com), while there have been creators who have 3D printed prosthetic hands for $10 (source: iflscience.com). These instances go to show that the current expensive costs for medical devices are not necessary. I encourage everyone to explore the diverse needs of individuals with disabilities and see if you can find ways to make their lives easier (both physically and financially) through 3D printing.

Thank You

I would like to thank you all for taking the time to read this post. I hope that you were able to find some of the information useful, and I would be happy to discuss anything further if you have any questions.

Arielle, thank you so much again for offering your insights and wisdom. As you may remember, BADM 395 is structured with 3 pillars: Learning, Making, & Sharing. Thanks to your sharing, our class has valuable takeaways in learning and making. I am excited to carry on this tradition by sharing our information with others and continuing the cycle.

-Scott Provenzano

Sources:

http://www.iflscience.com/technology/man-makes-3d-printed-prosthetic-hand-son-only-10/