Bust

Last week, I was not able to create my 3D Printed bust but I was able to do so this week! A classmate took a scan of myself that I uploaded onto Meshmixer. The original scan had some creaks and empty spaces but Meshmixer did a great job editing the scan. I was able to close the STL file by simply selecting a function called Make Solid and Close Cracks. Afterwards, I exported the file and opened it in Cura. The file was to small to be seen so I then selected all and scaled the item up (10000). After making some other edits in Cura, I then began the 3d printing process. In total, by bust took 45 minutes to print and I am thrilled with the results!

Project: Hydroponic Vertical Garden

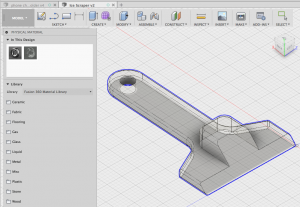

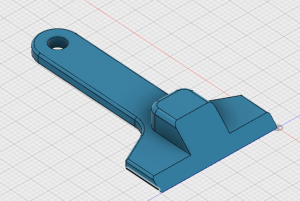

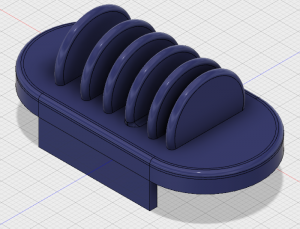

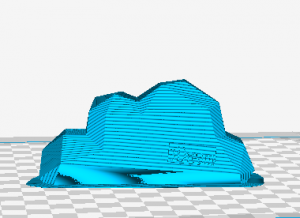

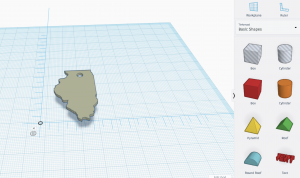

This weeks class was mainly devoted on creating the initial prototypes of our final project. My part in the project is to create a voronoi patterned bottle holder to fit a 2 liter as well as drip nozzles. I spent most of the weekend researching this history of voronoi diagrams and the results of my findings can be found in my last blog.

https://publish.illinois.edu/digitalmaking2018/2018/04/09/once-a-semester-project-voronoi-pattern/

I went to the FabLab in hopes of finding someone skilled in Meshmixer to help me with parts I found difficult, but the students there were more familiar with other softwares. Thus, I went to Youtube and found great tutorials! After familiarizing myself with Meshmixer, I really enjoyed working with the software and created a wonderful bottle cage that I initially felt apprehensive about.

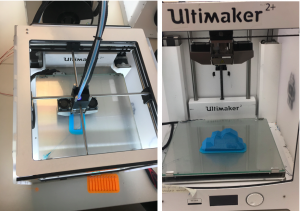

I was able to print the drip nozzle and the bottle cage. The drip nozzle was printed in less than an hour. Whereas, the bottle cage holder took nearly 20 hours to print! Initially, our team 3Dream wanted to have 8 plants but after taking into consideration how long it takes to print one bottle cage holder, we will now print 4 of them and 4 drip nozzles.

Thank you for taking the time to check out my blog and see you next week!