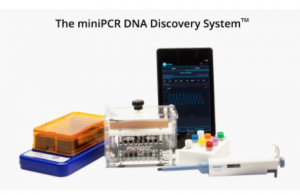

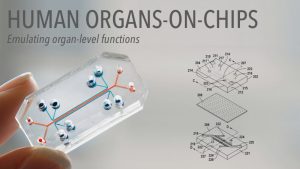

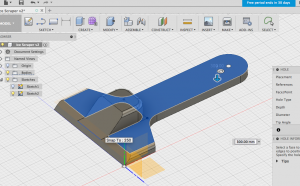

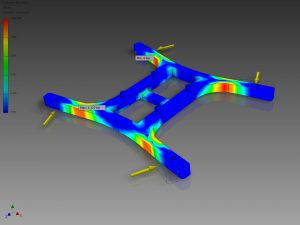

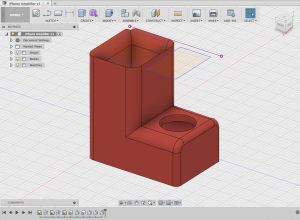

This week we had the pleasure of welcoming Dot Silverman. She graduated with a physics degree and began working for Autodesk, and now she is back here at school. Dot introduced me to the world of biohacking. Her past projects include printing with mycelium, human organs on chips, and portable DNA recovery devices. The mycelium plant pot, which is mainly mushroom fungi, was my favorite item she passed around. Despite how complicated these projects seem, Dot learned most of her technical skills on the job. She thinks that the lines between different disciplines are beginning to disappear. Projects nowadays are almost exclusively multi-disciplined. Students should be aware of this and continuously expand their minds. Their ability to work with those of different technical backgrounds is extremely valuable in the workforce.

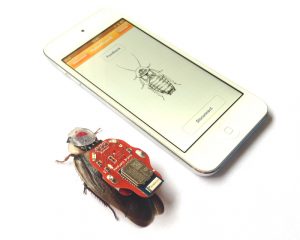

If you’re like me, you have zero prior knowledge about biohacking. Biohacking is the activity of exploiting genetic material experimentally1. To put it another way, “if you think of biology as a computer, and the way a hacker can infiltrate the system to make it work the way they want it to, biohacking can be easier to understand. The process of biohacking can involve a distinct combination of medical, nutritional and electronic methods to make the body function exactly as you want2.” So despite the nefarious sounding name, biohacking actually improves our health and quality of life.

Dot’s thoughts and experiences in the biohacking field were incredibly interesting. She also provided additional learning resources for the class to explore topics of interest. I dug deeper into the environmental characteristics associated with biohacking hoping to find a project idea. Ideally, my final class project will involve environmental sustainability in some way. I believe the planet is a critical issue that my generation must embrace, as mentioned in a prior blog post.

You’ll have to check back next week for my project selection. Though I haven’t finalized an idea yet, I was inspired by a company called Ecovative, a world leader in mycelium printing technology. Ecovative cultivates mycelium using farm waste, before “planting” it in 3D printed structures. As the fungus grows, the object materializes and becomes strong. These products are more normal-looking than you would otherwise think. If you don’t believe me, check them out. Mycelium is cheap, strong, and environmentally friendly, and thus Ecocative has profited from its unique business model. I appreciate the fact the company can operate while actively making our Earth a better place to live.

Sources:

https://en.oxforddictionaries.com/definition/us/biohacking

http://www.futuretechnology500.com/index.php/future-medical-technology/pros-and-cons-of-biohacking/