Guest Speaker

“Are you a professor?” I asked Mr. Banach, our guest speaker for this week’s class session. “No – but I’ve written 24 books and have taught thousands of people all over the world. So, you could call me a teacher.”

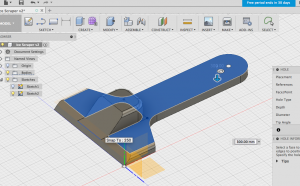

It was an excellent experience being walked through using Fusion 360 with Mr. Banach. It was evident that he has taught many students – he was patient and methodical in his teaching style. We gathered in a classroom instead of the MakerLab this week, to get a hands-on tutorial on using this common CAD software. Mr. Banach walked us through drawing lines to create shapes, extruding them to give them mass, and cutting them to give them depth. Together, we designed an ice-scraper that we could actually print and utilize. After our session, I felt like I understood the basic controls of using Fusion 360 to bring ideas into reality.

Class Takeaways & Activities

Overall, this class was an extremely informative one and a key session, I believe, as we begin to start digitally tinkering. Beyond the simple physical controls of using Fusion 360, I learned some key concepts about design aesthetics. For example, using the ‘Filet’ tool to round out edges really made designs much more aesthetic than cold cut lines.

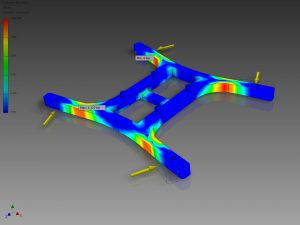

Furthermore, we learned the importance of design practicality, in terms of strength, material, and feasibility. We had to be aware of what material we were using to print a design based on its intended purpose. For example, using a brittle plastic (although cheaper!) would likely shatter our 3D printer ice scraper. We learned how to interpret stress simulations on our objects (very similar to a heat map), to see where the weakest points were. However, upping material design involves a much higher cost and “resolution” of the print. All these factors need to be considered when printing an object – it’s not as simple as design, click, print.

Tinkering

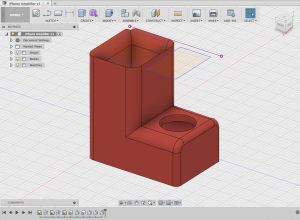

For my personal project, I decided to explore making my very own iPhone Amplifier. I looked at various designs on Thingiverse for inspiration, and then decided to take it my own direction. The iPhone would sit directly into the amplifier, sending the sound waves bouncing around the corner, amplifying in resonance, and coming out of the circular hole in front.

I’m not sure if this is a feasible design – my first thought is that there is a lot of excess waste with this model. Regardless, doing this personal project showed me that I am actually able to independently use Fusion 360 to model. I want to continue refining this design and see how I can potentially improve it.

Going Forward

Going forward, I want to grow my skillset in Fusion 360. Ultimately, I only know a few tools – extrude, filet, taper, etc. However, I believe that as I continue learning skills, my designs will get more complex and more feasible. I look forward to gaining this hands-on experience as I tinker – but I found an excellent additional resource online from AutoCad. It is a quick-start guide on using Fusion 360 and could be very helpful to our class,

I also thoroughly enjoyed being taught by Mr. Banach. His patience with all of us really made a difference and allowed me to feel comfortable speaking up if I was falling behind his instructions. I could definitely tell he knew his way around the software and was able to answer all of our questions about Fusion 360. I really like the phone amplifier you created on your own in Fusion 360! That is something I would use on a daily basis just around my house as I am getting ready in the morning. I also can’t wait to grow my knowledge about Fusion 360 and make even more things!

Great post Ajie. Understanding Fusion360 will be helpful when designing our class projects. The tutorial was memorable because Dan Banach was able to explain everything in simple terms. I also thought the properties of different print materials was an interesting point of the class discussion.

iPhone amplifiers are great products for 3D printing. I’m interested to know how much the sound quality changes in response to tinkering the design. Its great someone can customize any aspect of their design.