Guest Speaker

This week we had an amazing speaker share insights about Shapeways, an innovative company that created their business as a 3D printing manufacturer run online, and advices with prototyping. Shapeways allows users to upload files to their site, choose the material to print and they will print, finish and ship the item to you! There are also many items designed by people around the world on the shapeways site you can order and they will ship you such as jewelry, pottery, home décor items and even tech devices. At the beginning of the talk, Lauren gave us a virtual tour of the Shapeways space showing us each of the machines they use to print in and for different mediums. When deciding what material and machine to use to print she discussed knowing your needs. This includes:

- Scale of the item

- Strength & rigidity

- Budget

- Accuracy of design

After deciding on these 4 aspects, you can move to prototyping. At Shapeways they often say “All products are prototypes, but not all prototypes are products”. This put the idea of prototyping into perspective. With products, there is always something that can be improved upon therefore why it is okay to call it a prototype, however conversely, some prototypes need further iterations and improvements to become a working product.

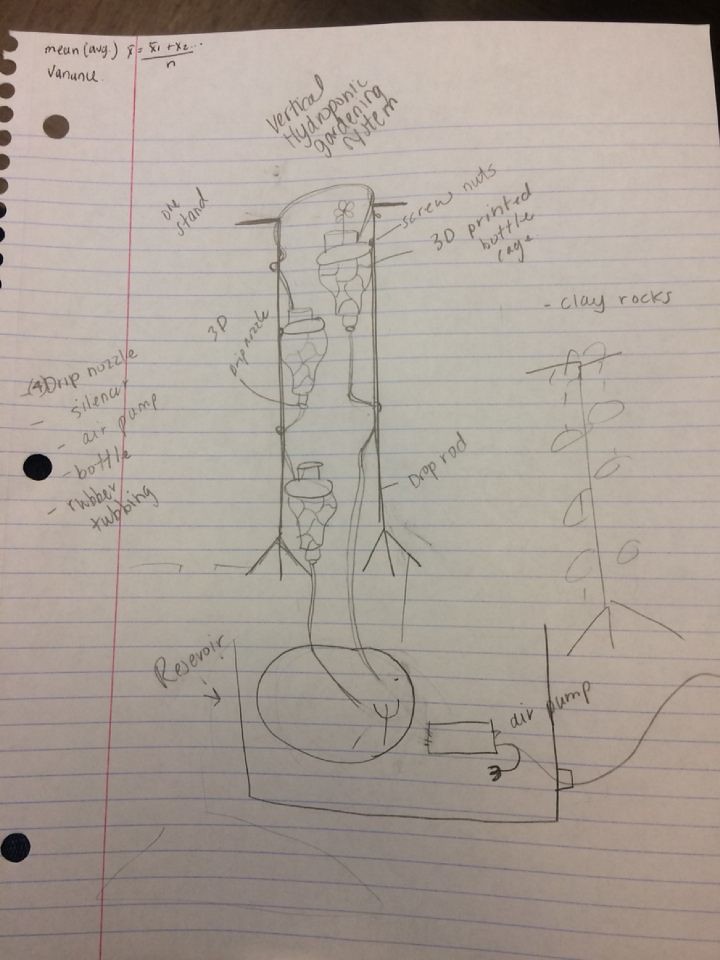

Prototyping our Project

The second half of the class we spent within our groups working on the prototype of our project idea. Our group, 3Dream has met a few times in the last week to make sure we are all on the same page with our design since we have gone through several ideas for a final project. The last 2 weeks we spent further researching hydroponics, the systems and the feasibility of creating a smart vertical hydroponics garden. During class, our team looked into the details of the structure, where we would place the plants and how they would be held up. We drew inspiration from both a coat rack in the classroom and a Christmas tree stand. For a hydroponic system, there needs to be a large basin of water to pump through the system so we spent time thinking of the best solution to incorporate a tub of water into the system. At the same time, we needed to come up with a base for the structure that would be stable enough not to easily tip over and kill the plants. A combined solution to instability and where to put the water led to incorporating the tub of water into the stand as a way to weight the system down while also concealing the tub making it aesthetically more appealing.

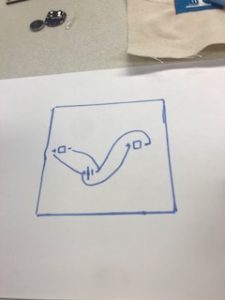

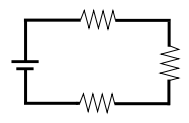

Next, using our intermediate knowledge of sowing circuitry into our canvases, we drew out the schematic of what our stitches would look like. It was like playing a puzzle game – you had to complete the circuit without letting any oppositely charged lines touched. I drew the head of my lion on a page and mapped out where I wanted my circuitry to connect. I realized that I did not have to send every thread back to the battery, but could continue them on to a similarly charged node at another LED, and then send it back (see design below). This saved me a lot of headache in stitching and made the design more efficient.

Next, using our intermediate knowledge of sowing circuitry into our canvases, we drew out the schematic of what our stitches would look like. It was like playing a puzzle game – you had to complete the circuit without letting any oppositely charged lines touched. I drew the head of my lion on a page and mapped out where I wanted my circuitry to connect. I realized that I did not have to send every thread back to the battery, but could continue them on to a similarly charged node at another LED, and then send it back (see design below). This saved me a lot of headache in stitching and made the design more efficient.

My lion’s eyes blinked to life! It looked even more aggressive than I thought with it’s contrasting pink/purple light. I completed the entire box and cut off the excess canvas around the corners. I absolutely loved how it turned out. My mom will definitely put it next to all my other ‘art’ projects from school, except this one is actually decent. I learned a lot from these past 3 weeks of hands-on making – my favorite portion of the class so far!

My lion’s eyes blinked to life! It looked even more aggressive than I thought with it’s contrasting pink/purple light. I completed the entire box and cut off the excess canvas around the corners. I absolutely loved how it turned out. My mom will definitely put it next to all my other ‘art’ projects from school, except this one is actually decent. I learned a lot from these past 3 weeks of hands-on making – my favorite portion of the class so far!