Before I start, I want to say that I am happy I took this course. I loved how it was a small group so that we all were friends by the end. I think that made it special and we were all on this journey together.

I thought this class was going to be extremely hard for me because I lack a lot of technical skills. I was nervous that I would not be able to keep up with the pace of the class. I knew it was going to take a lot of work. Also, I do not consider myself very creative so I thought I would be bad at coming up with ideas for the project.

Looking back these expectations were not met! This class was all about learning at your own pace. Each workshop, guest speaker, and project gave me hands on opportunity to learn new skills. For example, Fusion took me a while to understand, but with practice and patience I learned how to create and print my own model. Also, our sessions in the fab lab gave me an opportunity to create a design step by step. I used the platforms to import my personal pictures and all the way up to the final stage of printing and sewing. This freedom at first was scary because I felt lost, but I was able to problem solve through my projects.

I learned that I have very low confidence in my tech abilities. Whenever we were introduced to something new I was easy to give up and depend on teachers or students for help. Usually I get the help I need, but in this class I was pushed to out of my comfort zone and forced to learn new skills on my own. It was then I realized I can take on the task, but my initial mindset is that I cannot do it. I am smarter than I know.

I also learned teamwork in this class. For the past month my team worked together to build an idea from scratch. There were a lot of opinions and ideas involved, but we worked together to create the best prototype we could. I think we all contributed and were dedicated to this class. I hope to utilize these teamwork skills in my next job!

Finally, in this course I learned A LOT! Walking into class was the first time I had ever seen a 3D printer, I did not even know how to turn it on! From 3D printing, to fusion, to the fab lab, the design process, and more I decided to reflect back on my previous posts.

We learned about “The Maker Mindset” which is starting to be integrated into the education system. I learned that everyone learns differently and grasps to ideas in different ways. Personally, I have struggled with a reading comprehension disability and school has always been difficult for me. It makes me so hopeful for the future of students who struggle form learning disabilities that they will be able to demonstrate their knowledge through different ways of learning.

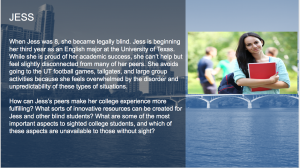

I learned about the six-step process that Design for America taught us. This workshop not only set us up for the remainder of the course, but also for our future careers. This process is a way to take a step back and really break down the problem. It helps you dissect your thoughts, which leads to better outcomes.

Our week with Dan Banach form Autodesk taught me fusion. He showed me how to build our own ideas. Getting an understanding of this platform has allowed me to try other platforms. What stood out to me about Dan was he teaching style. He made it easy to follow along and learn. I really appreciate that because I feel like I learned more. I am very grateful for learning this tool because I know I will continue to use it.

My most recent blog posts have been about our vertical garden project. I learned how to work with fusion on a more specific level in terms of measurements and shapes. But I also learned the importance of persistence and adaptability. A lot of our project did not go our way, for example the WiFi shield. Instead of putting energy into that aspect, we adapted and used sensors. I am very proud of the progress my team made and happy with our final product.

Thank you again Vishal!! This was a great class; it was unique in the best way. I cannot wait to show off my technical skills next year in Chicago!