My learning experience throughout this course had gone beyond my expectations. Though we only had class once a week the Digital Making Seminar had impacted my thinking process and brought in a different perspective of the world. Now, I would like to describe my journey and the various learnings and knowledge I had picked up on the way.

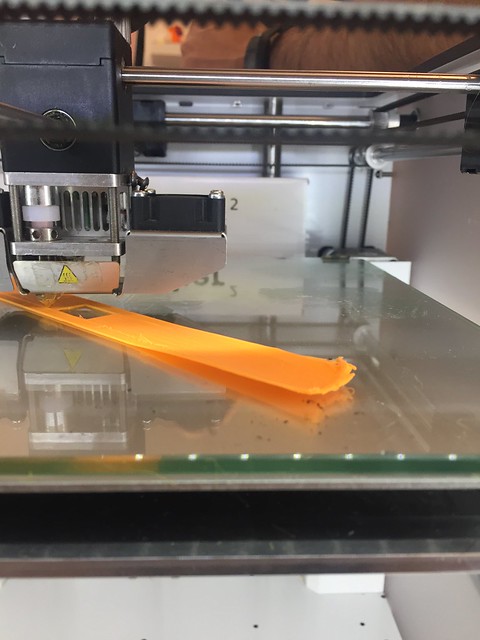

The first two weeks were more of introductory classes, allowing all the students to have a better understanding of what we would be delving into. We immediately were given the hands on experience to create our own 3D printed object after given a quick tutorial. I had learned about various sites and chose to use Tinkercad to print out an Illinois keychain. During the class we learned about the large amount of resources (ex. FabLab) available on campus for making and creating.

During the third week of class, Vishal had brought in UIUC’s Design For America. I really enjoyed their presentation because it truly helped my group, BCC Creations get our creative juices flowing. I realized how naturally creative the human kind is, it is easy for anyone to have the ability to design products or services through the design thinking process in order to meet a consumers demand. The group had taught us through a hands-on activity to create a prototype that would benefit our customer group: senior citizens. We had brainstormed various products that would allow a senior citizen to be more at ease.

Our fourth week we met with Jeff Smith from Autodesk who was teaching us about Fusion 360, the software allowed designers to design products or services from what used to many hours to only a couple of minute. Each of the tools in Fusion 360 were incredibly powerful unlike other softwares. With the step-by-step tutorial given by Jeff, I was able to create my own version of a perfume bottle I had through Fusion 360 after the session,

By the fifth week of class I had learned about different websites and softwares that could be used for designing, now I was excited to see how this could be incorporated to my final project. We met with our groups to brainstorm needs people have on the daily and create “how can we” statements. Furthermore, we had to make sure the statements were broad enough to solve the need and we weren’t delving into finding the perfect product for the need.

Week six, seven and eight we were at the FabLab working on creating a blinky box through three steps: Inkscape/laser cutting, soldering, and coding, My group started out with learning how to use Inkscape, we were given a template of the press fit box, we learned to change the settings for the laser cutting and added designs to our boxes. Once our designs were done we laser cut them, it was an interesting experience and the laser cutter had to be carefully monitored. The next week I learned how to make the lights blink on the hardware through coding. It was an incredible experience and a great learning process for me as my core classes don’t touch computer science coding or work with hardware pieces. In the final class we learned how to solder, it was a new experience for me and I learned how soldering melted filler metal onto metal joined objects by creating an established thin layer. Overall, I had a strong understanding of how everything came together to create the box and learned how all the components could be used, which would come in handy for my final project.

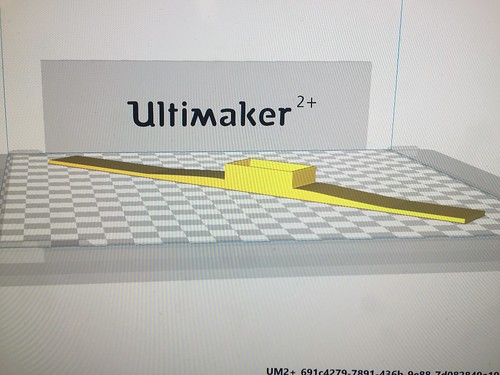

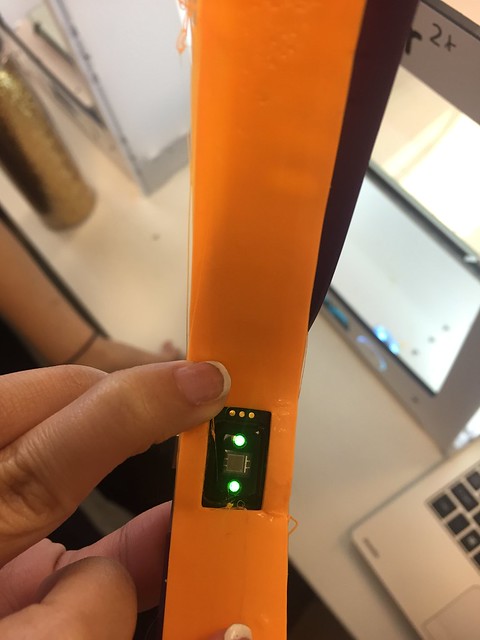

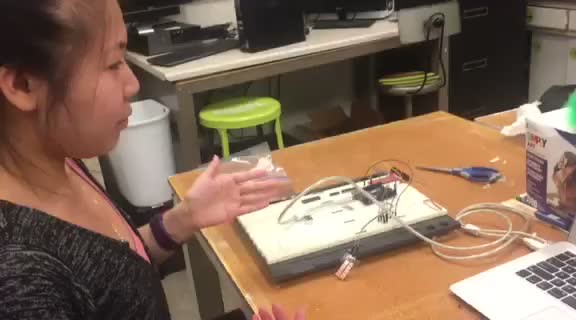

During weeks nine, ten, eleven and twelve we focused on our project, we went through prototyping, researching, improvements, auditing and making final adjustments. Once we decided on creating our “cheap” alarm system we began the prototyping process. We researched on the components needed for the hardware as well as the software side. Then we drew up a diagram so we had a clear understanding of how the hardware would look, what the software would need to accomplish and the shape of the housing. We gathered our components from Vishal and the FabLab. Throughout the process we had challenges, we had received help from the FabLab on useful components and my friend, Alvin Wu (Electrical Engineering) to assist us with the coding and putting together the hardware. In the four weeks I had learned so much about the product we were creating, I learned how to use the Raspberry Pi, searching up code as well as the incorporation of them, how the components worked and starting up Twilio so we could send text messages to the user. Once we were done with the product we worked on the housing which was a bit difficult to make the adjustments as we started out using Fusion 360 and moved on to Tinkercad. We made several adjustments to our housing so all the components could fit inside. FInally, we began our testing process of how our consumers would use it, we added on an extra text message so users would know when the security system was on and once it turned on there would be 60 seconds before startup.

Prior to taking the Digital Making Seminar course I had heard great things about it, not only from Vishal during an advisor meeting but also from students who had taken the course or were about to take the course during the same semester. I was very excited to see where this class would take me, as I had no experience with 3D Printing and all the functions we learned throughout the course. Thus, coming in I had little expectations but I was ready to experience a different side of what IT could offer. Now, that I have reached the end of the course and reflected on my learnings and experience I can definitely say the course reached beyond my expectation. I had not expected to be able to learn so many different aspects on designing and was really amazed by all the results as well as support. Throughout the process, I learned that even though I never saw myself as being a creative mind I was still able to create a final product design that would be suitable for our consumers need. I will definitely be taking all my knowledge from this course and apply it into my future career.

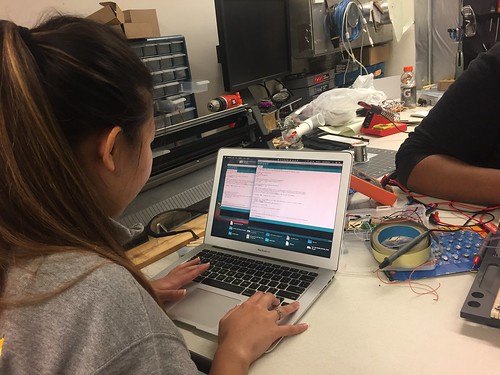

Arduino Software Application

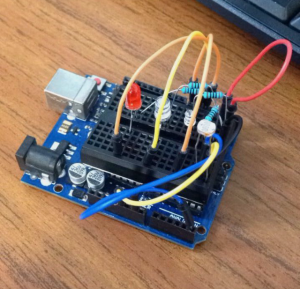

Arduino Software Application Test circuit for the final project

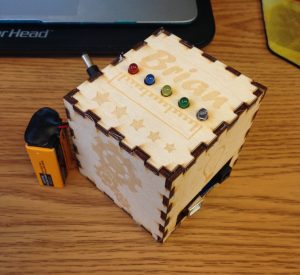

Test circuit for the final project The long awaited finished product

The long awaited finished product