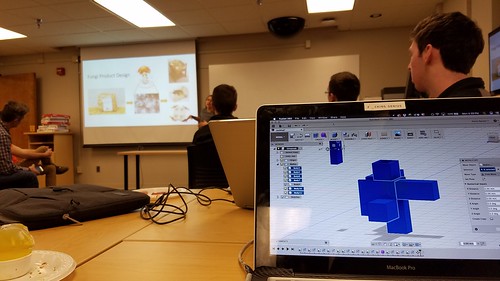

Jeffrey Smith from Autodesk held a workshop in class teaching us about the company and the Fusion 360 software. Autodesk’s Pier 9 is located in San Francisco Bay and is a facility that houses collaborations between artists, engineers, and technologists. One of their latest projects is a 3D-printed model of downtown San Francisco.

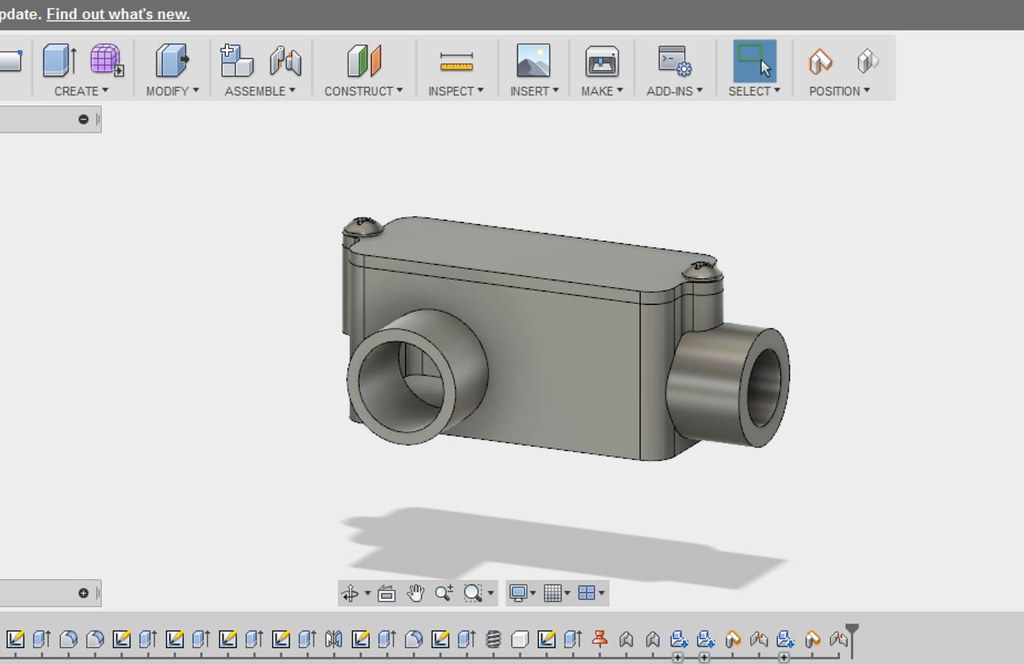

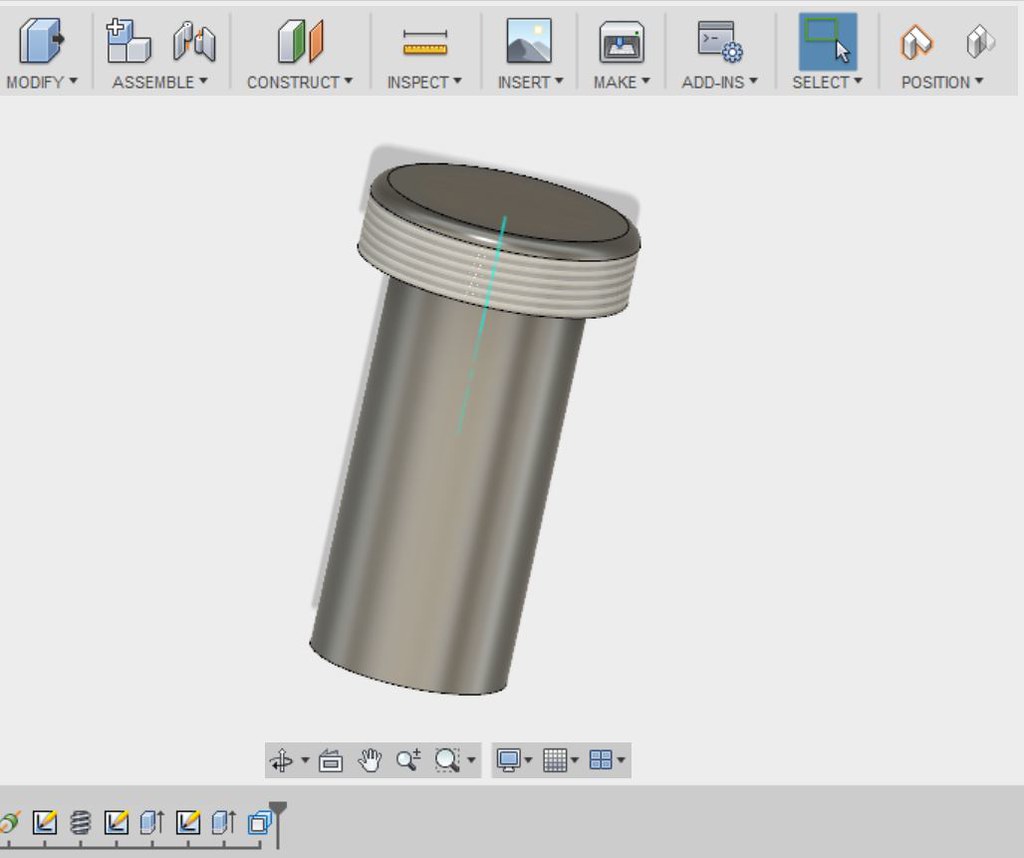

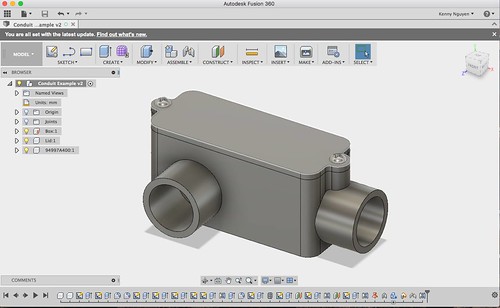

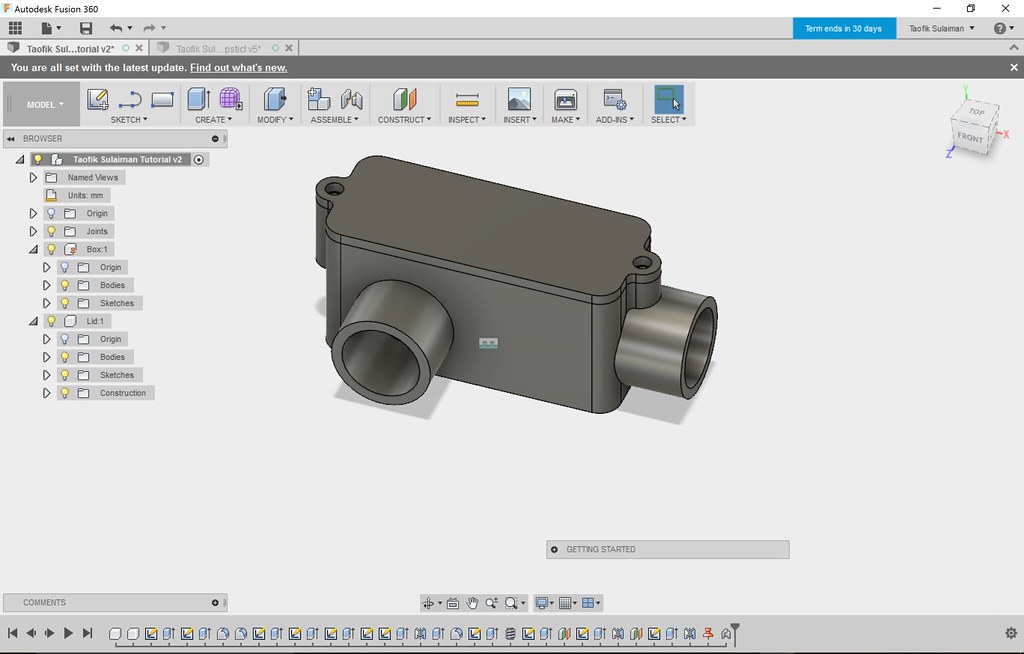

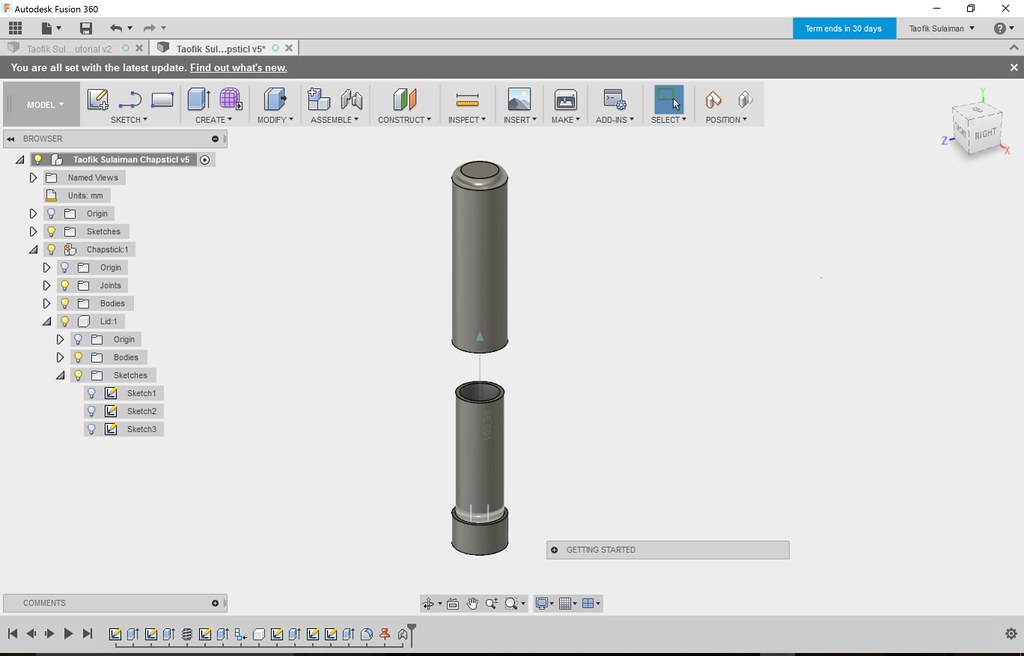

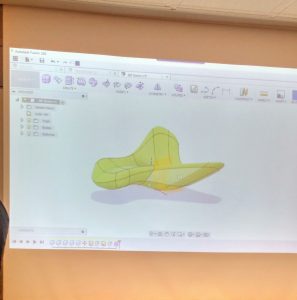

During the workshop session, we learned about the different tools on Fusion 360. I found the workshop to be incredibly helpful since I have never used Fusion 360 previously. Using the software, I tried creating a pipe that connected with a rectangular body. Other tools we experimented with were the sketch, modify, and assemble functions. Saving the best for last, we learned about the purple create tool. The tool allows us to deal with multiple faces and build complex, organic shapes. Jeffrey Smith create an aircraft design out of a rounded cube in a matter of minutes. I definitely want to practice using Fusion 360 more and utilize it in semester projects.

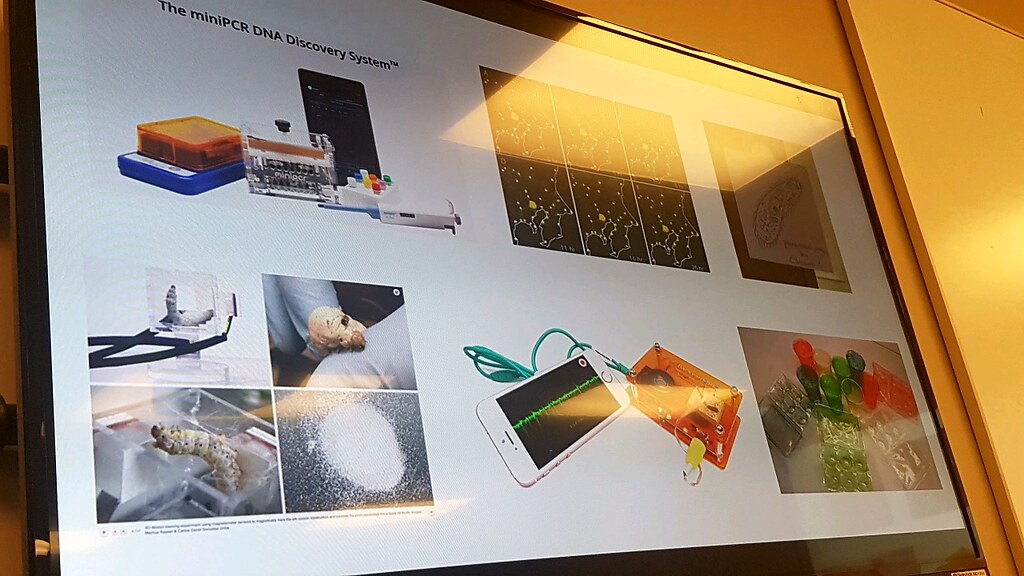

Dorothy Silverman presented on Biohacking, which manipulates the genes of organisms to usually create a product. Biohacking can also be thought of as DIY biology, where people of all backgrounds work together in small labs. Projects worth mentioning include using chitin to create biodegradable cups and plates and using fungi spores to grow furniture. I believe that the Biohacking movement is similar to the Maker Movement in that all sorts of people work together to create; however, Biohacking incorporates more sustainability in creating their products.

Merging Biohacking and fashion together, Suzanne Lee created BioCouture, a process in which clothes are grown using microbes. Biohacking is an exciting way to learn about biology and create things at the same time. I definitely want to experiment with the various processes involved to create sustainable products.