Our journey of creating the Door Sitter was challenging yet intuitive. Though the three of us in BCC Creations were not engineers, we had used our resources, research and knowledge to create an efficient product.

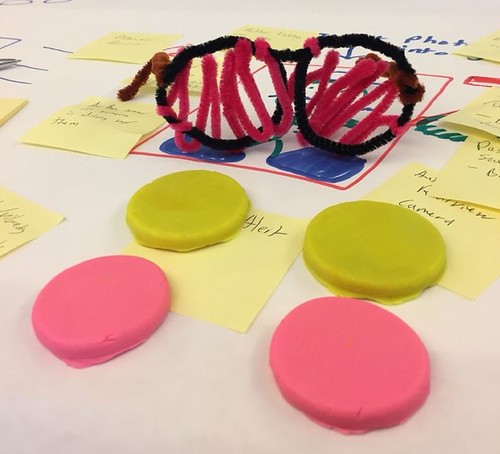

Prior to choosing to create the Door Sitter we went through a couple of ideas in our brainstorming process. We had first started out with identifying problems that were occurring in our own lives or to those around us. Vishal had stressed on using the Design Thinking Method which was a problem-solving process that allowed us to build up ideas with no limitations. Our first idea was based on our teammate, Carter’s experience with the recreational facilities on the U of I campus. He had noticed how many of the sporting balls were not at the correct PSI and having a decide to test it rather than manually doing it would be efficient. Thus, we decided to create a product to regulate a sporting balls PSI and pumping the ball to the correct amount. However, the more in-depth we got and furthered our research we realized that the product itself would be very complex and the pricing of it may not be suitable for the target consumers. Furthermore, we thought the product would worsen the problem and reduce the efficiency and we wanted to create a product that would be beneficial for more consumers.

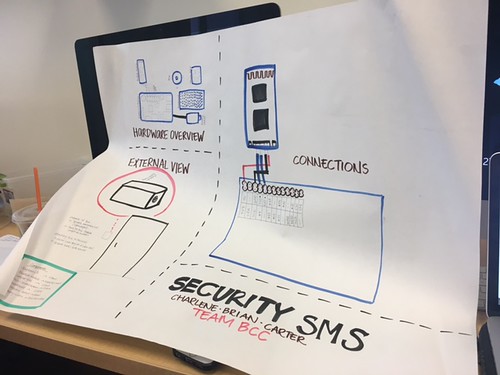

Our next idea had helped lead us to our final idea, a Chores Alert System. We thought it would be useful to those in the dorms with roommates, they would be alerted through a text whenever a chore needed to be accomplished. Though we all liked the idea we had continued brainstorming for more possibilities which led us to the Door Sitter. All three of us lived in apartments and had the realization that when we left during school breaks we had no way of checking for breaking and entering which had happened to many of our friends. So we came up with the idea of creating an affordable yet efficient alarm for an apartment that would be able to detect an intruder and sent a text message to the roommates of the apartment.

Making

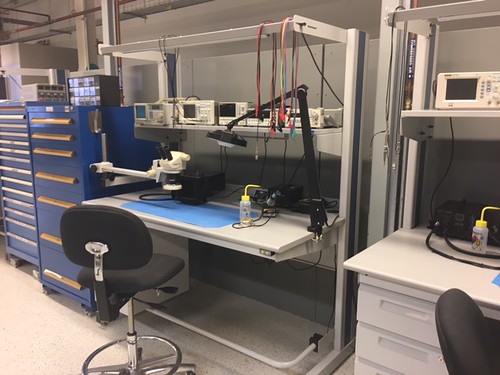

Once we finished brainstorming and settled on our problem to solve, it was time to determine how we were going to solve that problem, and how we could actually make that solution work. Fortunately for us, we had the MakerLab and Fab Lab at our disposal, not only for the physical components but also their expertise.

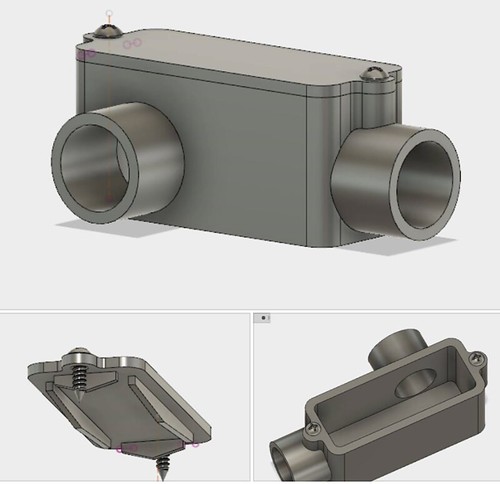

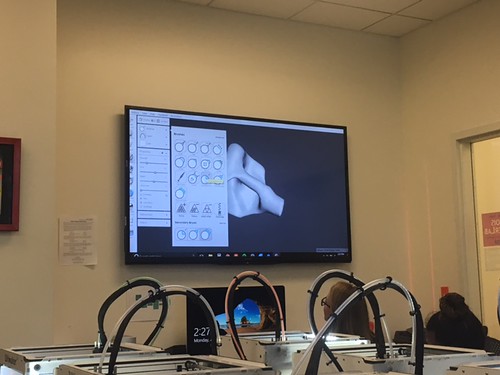

We knew that we wanted to 3D Print the housing for the system since we were familiar with the MakerLab, knew we could have multiple iterations, and the general low cost of 3D Printing. Before we could start designing the housing, we had to know what physical components our alarm system would need to function. Only after we settled on the technologies and hardware we were using could we design the housing.

Hardware

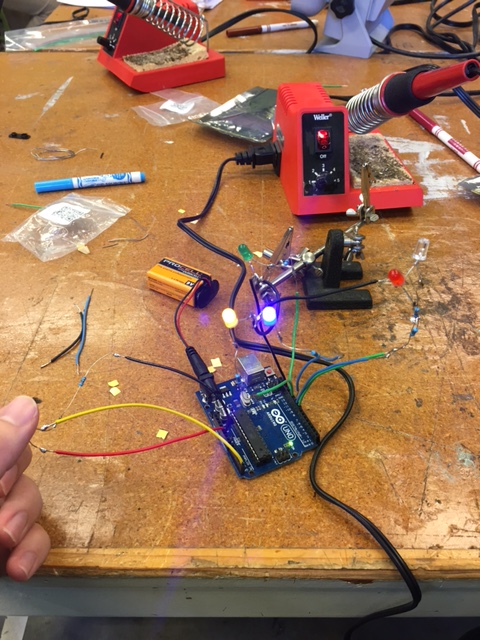

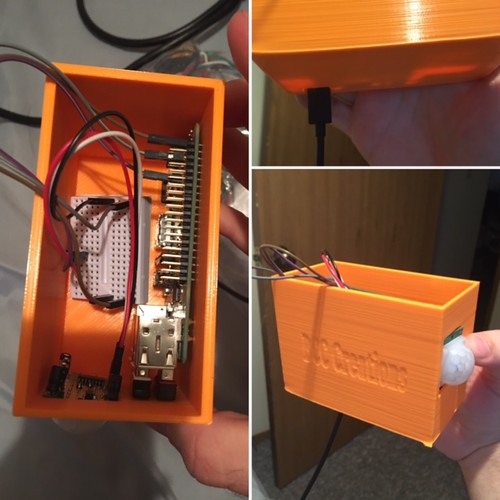

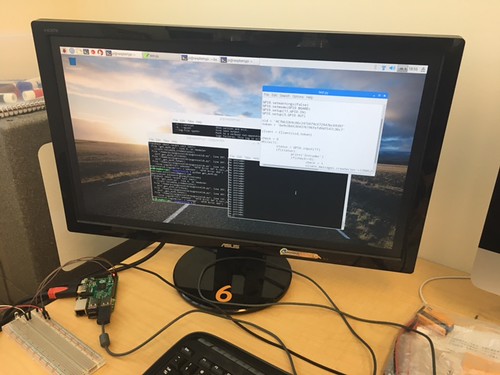

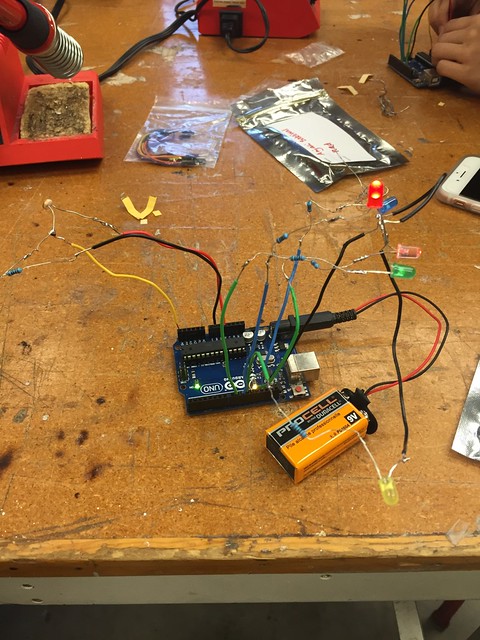

Initially, we planned on using an Arduino since we had used one and had experience programming it from our Blinker Boxes during our time at the Fab Lab. We thought we could use an Arduino with a bluetooth module to send notifications, but later decided to use a Raspberry Pi with Kootek Wifi adapter from the Maker Lab. To detect motion, we used an ultrasonic sensor from the Fab Lab. This allowed us to detect motion within a specific range that we were able to physically adjust to about 10 feet at a 120 degree angle. We also picked up male to female jumper wires to connect the Raspberry Pi, sensor, and breadboard together. We powered the device through mini-USB rather than a battery, and ultimately decided against the piezo sound buzzer. To interact with the Raspberry Pi, we used a keyboard, mouse, and monitor from the MakerLab.

Software

Once we acquired all the hardware for the security system, it was time to make the system actually work. We first had to load an operating system (Raspberrian) onto the device so that we could put in the Python code. We were fortunate to have Charlene’s friend lend us his technical skills with the programming. We used Twilio as a service to send the text message notifications to our phones when triggered by the motion sensor. To design the housing, we initially started using Fusion 360 since we had used it for the tutorial homework and our in class workshop with Jeff Smith, but we instead used Tinkercad for its simplicity. Although it is a relatively simple program, Tinkercad provided all the functionalities we needed, with far less complication.

The entire “making” process flowed very well. As the software was being programmed, we were simultaneously physically putting the hardware together. Once we knew how much space the hardware was taking up, we were able to design, print, and refine the housing. The MakerLab provided a great meeting place to work on the project together in addition to supplying the Arduino, wifi adapter, keyboard, monitor, power cord, and mouse. The Fab Lab was also a great outlet to receive advice from and supply us with the sensor, breadboard, and jumper wires.

Feedback & Testing

Given that security product solution is heavily user dependent, receiving feedback and testing the security “door sitter” was vital to allowing us to make adjustments to make the product function properly. The initial tests we ran ourselves focused on getting the device to accurately function as we created it. Functions such as the sensor detecting motion, ensuring the programmed Python sent the text message to a phone, and even connecting to wifi internet connection were processes that were refined by our testing. The range at which our ultra motion sensor detects motion was one capability we spent hours adjusting on our product. The ultra motion sensor has the capability to detect motion for a 120 degree 30 feet radius. We ultimately adjusted the sensor to only detect within 8-10 feet after much consideration about how our product is practically used. Since our the product is meant to run perpendicular with the entryway of a door, we did not want it to trigger a false alarm from movement far away. Taking practical considerations such as false alarms, how the product is used, and what makes most sense for the user were our primary goals when testing the security door sitter.

Furthermore, we tested the door sitter ourselves, collaborating with class members, and finally our team member Brian had his roommates test the door sitter within their daily routine. The feedback we received focused on two aspects of the door sitter. Firstly, where to install the product was something that was not intuitive to users outside of our team. It was not necessarily clear what location to velcro the door sitter box worked best. Another point that was brought up with the door sitter sensor location, was “what if a user has pets such as cats in the apartment? Would that trigger false alarms? “. We resolved this issue by creating an installation instruction manual, that would be given with the product for users who purchase the door sitter. The instructions tell the owner to use the provided velcro to put the door sitter on a wall perpendicular of the entry way that the user wants to be detected. It also has recommendations such as to install it high above if a user has pets.

Secondly, our classmates suggested that a user could easily forget to arm the door sitter before leaving there room / apartment. Our product is currently armed by simply plugging in the power cord. As in once a user wants their residence to be monitored they simply plug in the power, and after a 1 minute delay there motion sensor is monitoring the entry way. Although we could not figure out a low cost way to arm and disarm the door sitter remotely in the event that a user forgot to power it on, we did create a notification system that texts a user to let them know the system is on. This way a user can know based on their message history that the security system is armed, and the text message becomes a part of their daily routine

The feedback we received was generally positive, in that the Door Sitter was helpful in providing peace of mind and information regarding college students area of residence. Most importantly the critical feedback we received was beneficial, because it led to us improving our product by making it seamlessly fit into a user’s life.

Final Product

Our final product The Door Sitter, provides a solution to the need for low cost residential security. The Door Sitter is a personalized sensor set up by door(s) or window(s) to an apartment/house. When the Door Sitter is armed, it functions as an alert security system by immediately notifying resident (s) if and when there is someone that has entered the interior of a home. The Door Sitter notifies resident(s) when motion is detected via SMS text message, so that they are aware of what is happening within their residence and can alert authorities if need be,The customized 3D printing housing unit and instructions makes the Door SItter easy to set up with velcro, and more importantly keeps users mobily connected to the security of their home by knowing if and when someone has entered. Our product effectively monitors and notifies users of activity in a home. The immediate information the Door Sitter provides, gives users peace of mind knowing that they do not have to worry about a break in when they are away from their residence. Furthermore if there is a residential break in, with the alert system residents now have the information to be able to respond. Door Sitter can solve a need in that college students and property owners, have the ability to respond to a residential break with a low cost option for a security system.

Certainly, the BCC team learned quite a bit this semester in terms of the capabilities and process of solving a need through 3D printing, While we are satisfied with the progress we made in creating our own effective product that can help solve an everyday need, we also know that the product is far from perfect in terms of taking it to market. Do to the cost we did not pursue the potential of adding a camera to the Door Sitter. We do think finding a low budget camera to add to the exterior of the housing unit, would be useful in allowing a user to know not just that there is someone in their residence but who. Finally the actual cost of our product is a factor that we need to analyze more if we wanted our product to be on the market. The door Sitter costs roughly $50-$60 per unit with the all of the components. The feedback we received from our presentation suggested that even if we sold the Door Sitter at cost for $50-$60, that price tag still is a bit expensive for our target market of a college student. In our research we found that most in home door monitors are high tech and range from $120-$250. So while the Door Sitter would be a low cost option in comparison to what most security systems entail, we may want to pursue alternative components in collaboration with Jeff Ginger at the Fab Lab to make our product less expensive given our target market.

Certainly, the BCC team learned quite a bit this semester in terms of the capabilities and process of solving a need through 3D printing, While we are satisfied with the progress we made in creating our own effective product that can help solve an everyday need, we also know that the product is far from perfect in terms of taking it to market. Do to the cost we did not pursue the potential of adding a camera to the Door Sitter. We do think finding a low budget camera to add to the exterior of the housing unit, would be useful in allowing a user to know not just that there is someone in their residence but who. Finally the actual cost of our product is a factor that we need to analyze more if we wanted our product to be on the market. The door Sitter costs roughly $50-$60 per unit with the all of the components. The feedback we received from our presentation suggested that even if we sold the Door Sitter at cost for $50-$60, that price tag still is a bit expensive for our target market of a college student. In our research we found that most in home door monitors are high tech and range from $120-$250. So while the Door Sitter would be a low cost option in comparison to what most security systems entail, we may want to pursue alternative components in collaboration with Jeff Ginger at the Fab Lab to make our product less expensive given our target market.

Overall our team BCC creations, made a product that solves a need with the Door Sitter. We worked over several project ideas, learned new softwares such as Fusion 360, and went through many iterations of the design making process to create a solution. Using 3D printing and the Maker / Fab Lab to create a functioning and tangible final product, was beneficial in providing our team hands on experience of the capabilities of this technology and the maker movement.