This week we had our first encounter with the opportunities and capabilities of the Champaign-Urbana Community Fab Lab. The Fab Lab, although I was unaware of its existence prior to this semester, is a leading-edge open and collaborative workspace for design, creation, and printing through the use of computer-driven technologies, such as 3D printing, lasering, inkscape, and soldering. Below is a picture of one of the spaces within the workshop.

One of my favorite aspects of the Fab Lab is its openness to the entire community, irrespective of whether the makers are students or local community members. Everyone is welcome, and given the resources, to collaborate, share, and implement their ideas. One maker that we met was trying out a new machine called a “Water Color Bot” (the link to a YouTube explanation can be found here), which uses a specific software to produce complex water color paintings, using precise brush strokes and shading. While he was still becoming acclimated to the software, this is just one example of the various initiatives being worked on in the Fab Lab.

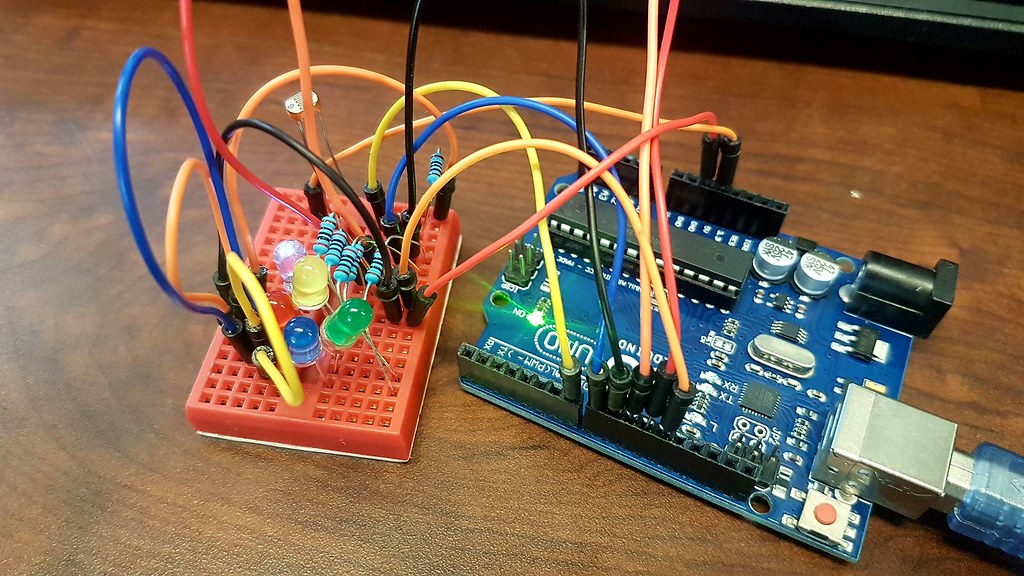

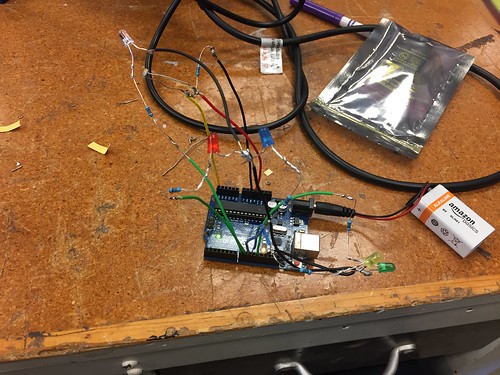

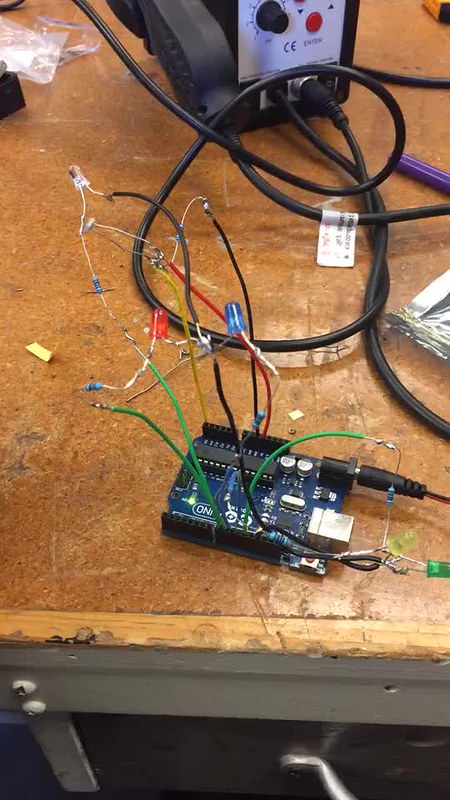

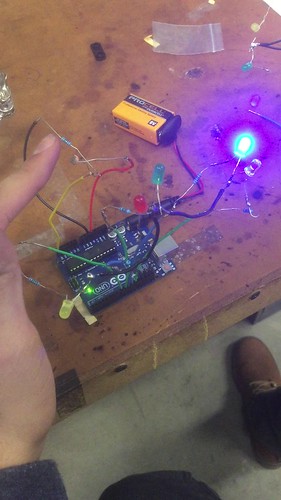

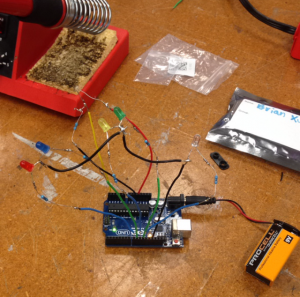

After receiving a tour of the workspaces, we were split into three groups, of which my group was assigned to utilize Arduinos to code behaviors into our widget. Arduino’s are an open-source platform that allows users to code certain behaviors and actions into an electronic object. In this case, our object that we were encoding was a photo resistor (light dependent resistor) with LEDs. Essentially, by wiring the LED lights to the light resistor and writing some basic “for” loops in the Arduino code, the LED lights would illuminate when there was no presence of light (when it was covered by a hand, for example), and would turn off in the presence of other light. I thought it was an incredibly useful and applicable first exercise in Arduino technology. Though the coding and wiring itself were complex, it was simple enough for us as first-time users to comprehend. In addition, I enjoyed being able to see a tangible result of our efforts, as opposed to just writing the code. The final product is pictured below. I look forward to engaging with the lasering/inkscape and soldering workspaces as well, and will definitely look to incorporate this technology into our final semester project.

Arduino Circuit

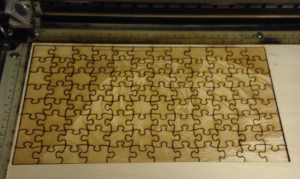

Arduino Circuit Laser Cut Tiger Puzzle

Laser Cut Tiger Puzzle