Our team, 3Dream, has had a lot of fun this semester going through the iterative process of ideation, design, prototyping, and testing a new product. During the ideation phase of this project, we thought of several different ideas however when we started discussing interests among our team, we found a common theme of the environment and plants. From there, we took this interest and started thinking about common problems among people our age in order to come up with a good “How Can We Statement”. We were drawn to the idea of a smart vertical hydroponic system as it solves a few common issues: rising air pollution in cities and stuffy apartments as well as providing a source of fresh produce or herbs in a small space (rather than needing a large yard to garden). We came up with three main guiding questions that we based most of the decisions in our project on.

- How can we improve the quality of life for city dwellers?

- From this, we came to a gardening system to improve the apartment atmosphere by improving air quality and hopefully reducing air pollution as well as providing psychological benefits such as improved mood, higher creativity and to de-stress the user

- How can we make it easier for young people to grow fresh produce or herbs within their apartment?

- How can we make this system affordable for the target market?

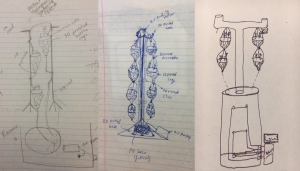

From these How Can We Statements, we developed a “smart” vertical hydroponic drip system. There are three main components that we focused on and divided up amongst the team. The Structure, which ended up being composed primarily of PVC piping and joint units with a 5 gallon bucket as the base and tubing for the water to run through within the PVC piping. The design for the main structure of our product was heavily dependant upon the available resources we had. As mentioned above, one goal was to keep this project very affordable and therefore we mainly borrowed or used scrap parts we were able to find (Specifically for the PVC piping, this was leftover in the basement of the FabLab and therefore we did not have to pay for it). The second main component of the project was how the plants were going to attach to the structure. We decided on a voronoi patterned bottle cage holder in order to be visually appealing. A voronoi pattern transforms a simple structure into a interesting, organic looking model and would provide nice design for the otherwise plain structure. The third and final aspect of the product was incorporating sensors into the system in order to make it a “smart” system. After much debate, we decided to incorporate a water level sensor into the bucket since the pH sensor was too expensive for our budget ($50) and the air quality sensor we had considered did not benefit the user as much as the water level sensor.

Prototyping:

The final prototype changed drastically from the initial sketch of our idea. 3Dream decided to make changes after user testing and group discussions about the practicality of our design. In the first sketch you can see that there were initially two main support poles and an external water basin. 3Dream concluded that having one main support would be more stable than two. For the base of the system, we initially wanted to 3D print a stand in a similar design to a Christmas tree stand with a water basin within however we did not realize at that point in the design phase that PLA printed products do not do well with water over time. We also believed that a connected water basin would be more stable, especially once it was filled with water and therefore this changed to be a 5-gallon bucket. There were several changes for the sensors, as mentioned previously. We initially wanted to be able to test the pH of the water in order to reduce the risk of poisoning plants with too many nutrients however due to the high cost of the sensor, we decided to incorporate a water level sensor instead so that the user would be able to tell how full the water bucket was and when to fill it with more water or turn off the pump (if the water was too low). Lastly, we reduced the amount of plants the system could hold so that the system would be more compact. While most design changes were motivated by pursuing different goals, the design was also highly dependent upon the materials 3Dream was able to gather. We kept costs extremely low by repurposing scrap materials and recycling consumer products. Our prototype would likely differ had we purchased all the materials from a store.

User Testing

Some of the improvements to the prototype design are directly attributable to user testing. 3Dream spent ample time drafting the testing protocol in hopes of constructive feedback. Test subjects were asked various questions regarding their knowledge and opinions of hydroponics. Next, the test subjects assembled the prototype with as little direction as possible. During this time the test subjects responded to more prepared questions about design aspects and consumer demand. 3Dream realized the prototype looked more like a science project than commercial products in stores. The feedback the team received definitely confirmed that idea, as well as the belief that this product would serve a smaller, niche market. The user testing helped to determine a few different aspects of the project (such as the amount of plants or the sensors incorporated) however we mainly used the feedback gained to lead into things we could improve on for future prototypes and the final product if it were to go to market.

Future Improvements

User testing shed light on the path towards future improvements. First and foremost, aesthetics was the most obvious improvement. The tricky part is that ideal aesthetics vary drastically from consumer to consumer. 3Dream has several ideas to address this issue, which include: adding felt coating around the bucket, painting the pvc pipe, and printing a comprehensive Arduino box to showcase the LCD display while hiding the electronics components and arduino. Varying consumer tastes demonstrated that customers desired more customization. To better align the prototype with those values, 3Dream will develop multiple variations of the drip system. Some customers might want taller systems so that they can grow more plants. Other customers may want wheels on the bottom of the bucket for mobility or wall attachments to hang the system. Carrying the prototype from the FabLab to the classroom showed 3Dream how difficult moving the hydroponic system currently was. Adding air quality and pH sensors would drastically increase the cost, but experienced growers could find these features improve the product. Many people, including the test subjects, might be turned off by these features and the complexity they would add. Multiple product variations give 3Dream the versatility needed to satisfy both groups of customers.

Cost and time restraints prevented 3Dream from attempting to grow plants. Plants would automatically improve the prototype’s aesthetics. 3Dream identified 2 types of plants a user of this system may consider: air purifying plants and garden herbs. Depending on the primary objective of the user one may by the system to increase air quality while another may only want the system to grow herbs and vegetables. In terms of air purifying there are three top plants that grow well hydroponically while simultaneously cleaning the air. The first plant is the garden mum, which is the air purifying champion according to NASA. It should be planted at the top because it needs direct sunlight. Next up is the boston fern, which also excels at purifying the air. It doesn’t need as much direct sunlight as the garden mum, so it can be grown in the middle of the system. Last but not least is the peace lily. This plant is shade loving, so grow it in the first pot up from the ground.

Takeaways

Building this comprehensive prototype has taught our team many lessons, the first of which is to utilize resources on campus. These resources were essential when dealing with the challenges that arose each step of the way. We saved hours of time that otherwise would have been spent researching by asking the right people the right questions. One employee at the FabLab, Brandon, gave 3Dream potential solutions for the functional requirements of the prototype. Humans have learned to solve many problems throughout the years. You should utilize this progress instead of reinventing the wheel when problems arise. It’s always a good idea to leverage resources when available.

User feedback is another area that should be leveraged to create a product that users desire. Designing the testing protocol forces you to evaluate prior assumptions in a more objective manner. Using this as a basis, your questions will yield better results. Your mindset should be focused on continuously improving your idea, not validating your beliefs. Finally, this project allowed our team to expand our knowledge of several different systems. We were able to improve our Autocad skills designing the plant cages, acquired electronics skills programming an Arduino and LCD screen, while also learning about hydroponics systems and what it takes to design and create a working prototype.

Link to presentation: https://docs.google.com/presentation/d/1cobksQYS-JXenx-w7A9ZiX_uKf4AMBK-8y2yNzubJXo/edit?usp=sharing

Link to Instructable:

https://www.instructables.com/id/Smart-Hydroponic-Vertical-Garden