Jeff Ginger

This week in class, we had a guest speaker come in a give us fascinating presentation. Jeff Ginger is the director of the Champaign-Urbana Community Fab Lab. When he was speaking though, I got the impression that he truly embodied the “maker mentality” we’ve discussed in class. He embodied the idea of a print-sharing economy, where community members had free access to the designs, hardware, and assistance needed to make their dreams a reality. I appreciated his vision – he was truly passionate about enabling another generation of future-makers. I enjoyed seeing the real-life examples of community members that utilize the Fab Lab to grow their small businesses. I also learned that there is a global fabrication lab network! I had no idea that you could visit a different country, and find a lab with a standardized set of fabrication tools. I found it fascinating that there are both regional and national conferences, where makers all over the world get together to share ideas, get critiques, and collaborate on projects. I am very excited to visit Jeff Ginger’s Fab Lab (just right across from ACES…I passed this building every day my freshman year and had no idea what it was!) and learn how to best utilize these free resources.

Considering that our MakerLab only had 3D printers, I look forward to learning how to truly ‘fabricate’ products using a variety of tools: laser cutters, sower machines, circuitry, etc.

Class Takeaways

This week in class, we finally got out hands on the the Cura software and the Ultimakers! Admittedly, it was an unfortunate week to not have our actual professor teaching (Vishal had the flu); the students were a little frenetic and not the best teachers. However, a lot of group-learning and collaboration happened – and we were able to make things happen!

We started by learning how to use TinkerCAD – it was a surprisingly usable tool. The user interface reminded of an iPhone game – very fluid, logical, and responsive. In just a few moments, I was able to import an Illinois keychain and render my name on top of it. Though I did not print this, I was pleased with how smooth the process went.

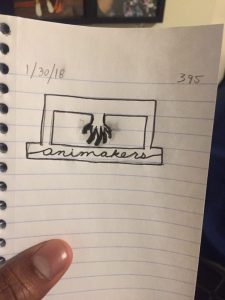

My team’s name is “Animakers” – a combination of ‘animate’ and ‘make’! My team spent the second half of class trying to render our logo. It was more difficult than we expected with our original creation (we needed a lot more experience on TinkerCAD) so we modified our original design. Instead of a 3D Printer with a hand for a nozzle (see original mock-up below), we decided on an outstretched hand holding the world on it’s fingertips – literally representing the world at our fingertips to make.

After a lot of self-learning, we were able to initiate the print! It was scheduled for over six hours, and we have yet to return to the MakerLab to see how it went…either way, it will have been a learning experience! Things will only get better from here.

One topic I want to continue learning about is supports – the process of printing temporary structures to support a complex design that cannot initially stand on its own. I found this 3D Hubs resource to be incredibly insightful…I suspect mastering the art of supports will be key to creating unique and powerful prints!

Hi Ajie,

I look forward to reading more of your posts as you dive further into supports, especially because I have always been fascinated by 3D printers and wondered how they sometimes make such gravity-defying features. Through reading your post and learning from the student teachers in our last class, I came to better understand the idea of supports. I originally thought that these supports would be permanent (or need to be removed with tools). However, through experimenting with our 3D printers, I was able to see that our printers actually create supports that are so thin that they are able to be peeled away with minimal effort (using fingers). I like the article that you linked in your post because it showed much more thick and detailed supports (which I feel would be much more useful in larger-scale prints).

-Scott Provenzano

Hey Ajie,

I liked your design and I thought it really turned out nice once I saw it in class. I am also looking forward to visiting the FabLab especially because I want to see all their equipment we get access to. I think it will be an exciting way to develop new skills!

Your team name is very creative, as well as the design! I also agree that with more experience on TinkerCad, creating a customized designed would have been easier. But, your final design that I saw in class looked amazing and actually inspired our team to change our design a bit.