Laser Cutting

We were back in the Fab Lab for class this week, and we focused on designing a wooden laser-cut box. The objective of making this box was to get familiar with finding silhouette designs that could be etched in with laser onto wood. We also learned how to get familiar with the software used to design specific cutoffs for wooden parts. The open source program we used to design our wooden-box was very user friendly.

The box looked something very similar to this with a finger-lock contraption. We laser cut out 5 pieces of wood with the ‘finger-pegs’ that interweaved with one another to make a secured box.

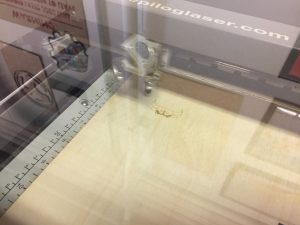

Pictured above is a real life picture of the laser cutting the plywood. The design I chose was the Chicago Bulls logo, and as you can see, the laser cuts out a very precise replica of the design you choose.

When the actual box came out, there were a lot of sides that needed to be sand-papered down because of the roughness of the wood. Other than that, everything else went great. The print matched the exact measurements I chose on the computer program. With learning how to use the different technology at the Fab Lab, I’m looking forward to go on my own time!

I think the coolest aspect of the laser machine is its ability to switch between cutting and silhouetting. I watched the laser machine seamlessly switch between these two settings. Did you see how sometimes the wood would momentarily catch on fire? My first print was ruined by fire, but I managed to assemble the second one.