This class session focused on finalizing our project ideas and delving into the rapid prototyping phase of the project.

Ultimately, after weighing a handful of options, Team MakerLax chose to begin creating a prototype for a tie knot helper. Essentially, what this product does is allow users to tie a tie on-the-go, with little hassle. We believe this idea is useful for four main reasons. It is narrow in scope, with the tie helper serving a singular purpose and not attempting to accomplish a variety of tasks. It is relevant to our current environment, as the majority of college freshmen that we have surveyed have little-to-no knowledge on the intricacies of tie knots. It is convenient, with the ability to be used in virtually any environment. Finally, it is feasible and holds a competitive advantage over utilizing other forms of education, such as YouTube videos. While how-to videos are effective in some cases, they do not offer the physical presence offered by our product, nor can they be used while running to an interview.

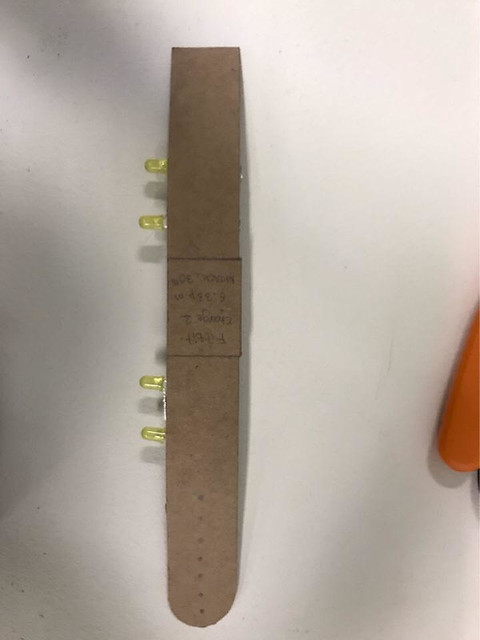

Above are the two initial designs we created, both composed of cardboard. While the one on the right offers more guidance, the one on the left can be easier to detach once the knot has been tied. One of the primary challenges associated with a product like this is being able to reuse the template, which requires the user to have the ability to remove the product once the tie has been finished. In order to do this, our next step is to prototype a metal using a flexible plastic filament, that can be bent or maneuvered in such a way as to be removed as the final step. The other idea we developed was to give the product the ability to be folded into smaller pieces, similar to many of the designs we have seen in the MakerLab. This would require more advanced engineering and design of the product within Fusion360, however we believe that it will ultimately benefit the user in the long run, as the template will be able to fold and fit into a suit pocket or a briefcase on the way to a meeting. Next week, we plan on printing a few plastic prototypes that will allow us to determine the true feasibility of the design, as well as potentially offering other ideas to incorporate into the product. Ultimately, we hope to decide on a final design so that we may begin finalizing the project details.