It’s hard to believe we have been away from the Maker Lab for over a month! Week 9 found us back in the Maker Lab after a week away for Spring Break and the previous 3 weeks away at the Champaign Urbana Community Fab Lab. I think all of us were glad to be back “home.” This week we focused on design and prototyping as we start to bring our project ideas to life.

One of the most important points we learned emphasized that design sketches and prototypes are by no means a final product. They can (and should be) rudimentary, use household items, and use temporary solutions. David Kelley, of IDEO, in this presentation says, “Design is an iterative process.” The quicker you can get feedback from a product, the more successful it will be. Each presentation allows you to get more feedback, and people will always tell you “everything that is wrong with it.” Kelley continues in this video to talk about the design of Apple’s mouse, and how a temporary prototype solution to keep dust off the optics can turn into a permanent part of the design. As you improve, you will quickly have a better prototype on your hands and you can even start using custom parts. Jeremy Losaw in “ProtoTYPING: Tips to Get Started on Your Product Idea” says “3D Printing is a great way to get custom parts quickly.” Luckily for us, we have access to the Maker Lab and Fab Lab to make those custom parts with the very talented staff in both labs.

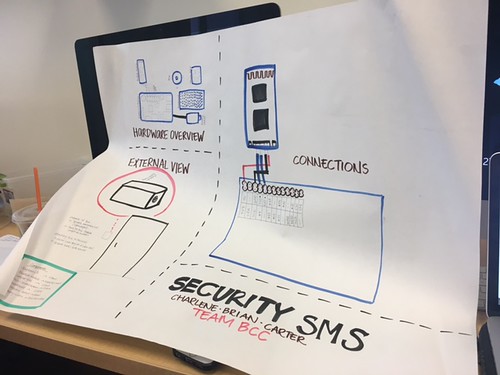

After going over all these discussion points, it was time for our groups to split up and start designing and prototyping. My team, BCC creations, settled on making a low cost security system to provide college students some peace of mind when they are away from their apartments. We have named our product “Security SMS” and will use motion detection to alert of unauthorized entry. When someone enters the apartment, they will have 10 seconds after the motion detector is tripped to turn off the alarm. Otherwise, an alarm will sound and a text message will be sent to the roommates living in the apartment. We will use a Raspberry Pi with Twilio to send the SMS, Piezo for the alarm, and an ultra sonic sensor for the motion detector. We will 3D Print the housing that will hold the alarm, which can be attached to a wall with Velcro. Originally we considered using a Bluetooth unit for the SMS function, but after I went to the Fab Lab during class, we decided to try Twilio. Aakanksha at the Fab Lab offered to help us, and Charlene and I have friends studying Engineering that have offered their talent to us should we need it when programming. Our next step is to start working on putting together a circuit and programming the Raspberry Pi. When we know how big the circuit will be, then we can start prototyping the housing for 3D printing. Although it may be tricky to design in the software, we presume it will be an easier task that working with the technical specifications of the alarm. Regardless, with the three of us working together, we are all excited to prototype!

Hi Brian,

Great post! I like how you included outside sources reiterating the fact that prototyping is an ongoing process, as people (I confess I do this as well) often get caught up wanting to get the “right” model the first time and become very stubborn with it. Also, I really like your team’s idea. One thing I’m concerned is just if 10 seconds would be too short since that might result in lots of false alarms. Maybe there’s a better way to set up the system so it’s effective but also not too inconvenient?

Hey Brian,

Awesome idea! That really got me interested and sounds like it could be super helpful. I’m glad to see that going to the Fablab paid off, and you guys are already doing some fairly complicated stuff thanks to your time there. I’m very excited to see your guys final project and hope you all the best in the upcoming weeks!

Hey Brian,

I love your idea a lot! It seems very ambitious and I’m very excited to see how it’ll turn out. I love that you’re working with a Rasberry Pi as well and have already figured out who can help you out when it comes to the more technical aspect of making the whole thing work. Really excited to see the working prototype when you guys are all done!