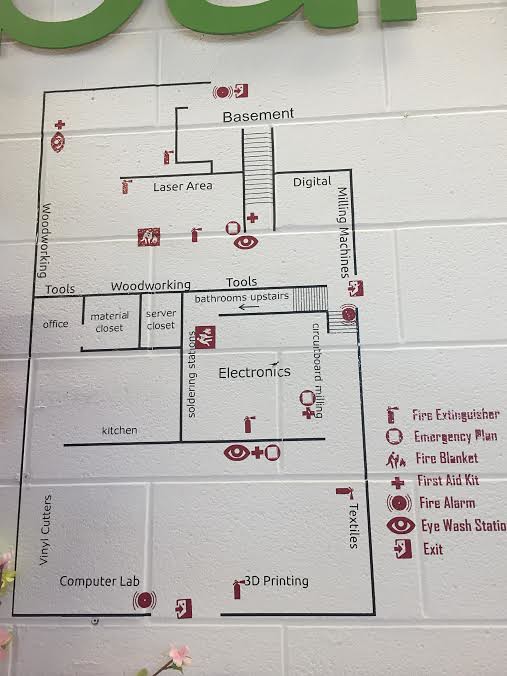

This Monday we entered a whole new world and expanded our knowledge by going to the Champaign-Urbana Community Fab Lab. The CU Fab Lab was one of the most creative spaces I have ever seen with stickers coloring the walls and trinkets hanging from the ceilings. However, it wasn’t the décor that was the main star of the Fab Lab. It was the type of machines and the shared knowledge available to the public. The Fab Lab provided those in the Champaign-Urbana area with access to a plethora of fabrication tools such as a laser engraver, CNC routers, 3D printers, scanners, electronic cutters, digital textile machines, small board electronics, graphic drawing tablets, and advanced software. We were fortunate enough to take a tour, with Jeff Ginger, of the colorful facilities as shown below. The place was a well-organized fascinating maze with areas such as a computer lab, 3D printing area, textile workshop, electronics section, soldering stations, circuit board milling, milling machines, digital area, laser area and wood working.

Panoramic of Fab Lab Entrance

Map of Fab Lab

Colorful wall of Fab Lab

Awesome models near the entrance

Cool Display from Textile Area

I truly loved that this workshop was a haven for makers. There were so many resources to spark imagination, develop designs and create. My favorite part of this space, was that it encouraged collaboration. Many projects were DIW which means “do it with others”. This gives the mentality that the people around have diverse experience and can be possibly the missing piece to the puzzle. This idea was further implemented when our groups for our final presentation was split up so that each member learned and did something different in the workshop after the tour. Each week we would rotate into another area. I think that this is extremely beneficial as each member would have an entirely unique experience with each workshop. This would allow each group to work together and ultimately do the project with each other and utilize each individual experience.

Textiles Tour

Amazing Watercolor Machine

Woodworking Tour

When the tour was over, I was placed in a group led by Holly Brown (Lab Manager and Instructor) and Clinton Gandy (Lab Assistant) where we learned how to prepare laser cutters. We were using a universal laser cutter to create a personalized box. We sat at the computers in the woodworking area and utilized the advanced open source software. We used Inkscape which was very similar to Adobe Illustrator. I’ve had experience with Adobe Illustrator in my high school graphic design class, so I didn’t struggle too much with it. I found it so interesting that so much work came into preparing an image to be cut with a laser. Each line to be cut must be RGB (255,0,0) with a strike width of .001. Images to be rastorized must be black and white. I asked to if I could venture into the gray-scale area, but for simplicity’s sake, Holly advised me to do a straight black and white image. She did however mention that gray-scale images could be etched on, but it requires more preparation and time which we did not have. I however researched more on this and found a wonderful YouTube video on how to prepare gray-scale images to engrave on wood. Expanding my knowledge in how to cut and engrave with a laser printer helps me become prepared to execute my final group project given the need of laser cutting or rastorizing. Additionally, this knowledge and experience can help me further assist my fellow peers should they approach me for help.

Woodworking and Laser Area

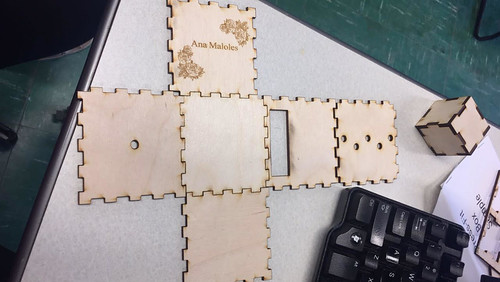

Press Fit Box Example

Holly Modeling a Press Fit Box

Black and White Design I chose

Press Fit Box Parts Preparted on Inkscape

While going through the workshop, I was able to follow very quickly and intuitively, most likely due to my previous experience with Adobe Illustrator. I ended up finishing my project first. I had help with calibrating the laser (as shown in the instructions on the wall in the images below), and then I started the laser cutter. I found this laser cutting and rastorizing so fascinating. The design image that I chose was etched on the wood so easily. The design I chose was very detailed and I did not think that the laser would capture so much detail in a small area but the laser was so fine and precise that the image turned out beautifully. From this workshop, not only have I learned how to cut and engrave with lasers, I have also realized how flexible these laser cutters are and how these laser cutters have a tremendous amount of applications and uses in product design (here’s a video on many of the applications!). Overall, I hope to use this knowledge in creating my groups project.

Universal Laser Cutter

Instructions to Calibrate Laser Cutter

My Box Design Being Printed

Intricate Design

Pieces attached to each other before put in a cube.