Prior to this week’s session with Jeff Smith, I had downloaded the Fusion 360 Software and begun experimenting with the various settings by following the Absolute Beginner Videos created for Fusion 360. When I first started using the software I was having some difficulties trying to follow the videos, as I did not have much experience with design and creating products through a technological format. However, I was eager to develop more skills during class and build a better understanding of the software as well as the company, Autodesk, itself.

Learning about Jeff’s experiences after college was incredibly insightful. Though he had very positive moments he still went through hard struggles, however, those struggles had helped him realize the strong connections he had unknowingly built and the skills that he had developed from being on the work force for so many years. With all his skills, Autodesk had found him to be incredibly competent in a position with them and he acquired this opportunity because Autodesk was once his client. Though he went into Autodesk, he had no knowledge of the software he would be teaching to college students. Now hearing how he has excelled in Fusion 360 only brings a light into my learning abilities, I could achieve the skills he has in using Fusion 360 for any future projects and creation of products or services. As Jeff spoke about Fusion 360, I was wondering what the intention of Autodesk providing free software for students were. Sure, we were a good group of individuals that would be able to learn the software quickly, but what the ultimate motivation for them to do so. Jeff had explained that the commercial companies that acquired Autodesk software’s required them to teach college students because they needed to be sure there were individuals that would be able to use these products to create innovations.

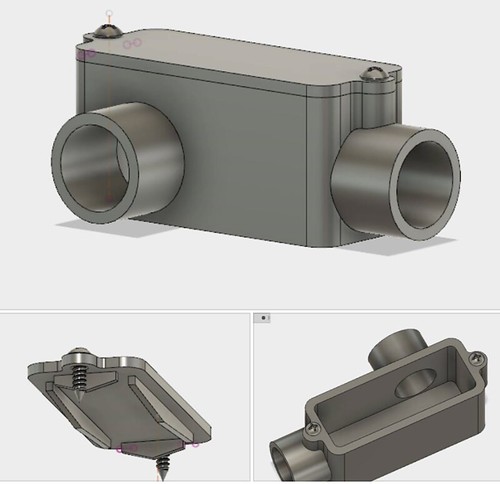

Fusion 360 has provided a way for designers to design products or services from what took hours to only a couple of minutes. We are all eligible to work on live versions of models, making it possible to bring designs to life. The software is allowing creativity to becomes designs within minutes. Furthermore, the software does not force the designer to be in a certain location but could design in the safety of one’s own home and still be able to collaborate with others. Through Jeff’s initial training of Fusion 360, I was able to have a grasp of the tools that were a part of the software. It’s amazing how powerful the tools are compared to other software’s that would require three moves; Fusion 360 would only require one. Overall, I enjoyed the experience of being able to have a hands-on learning of this new software, and I hope to be able to keep creating through this method.

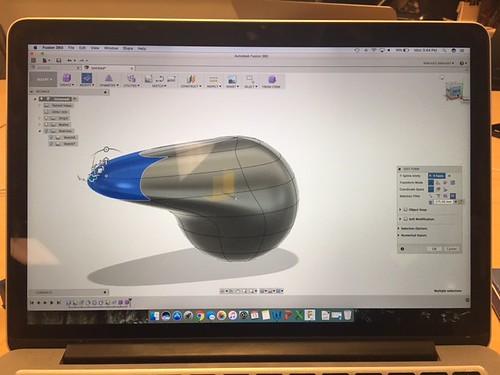

Here is a model of a perfume bottle created through Fusion 360.