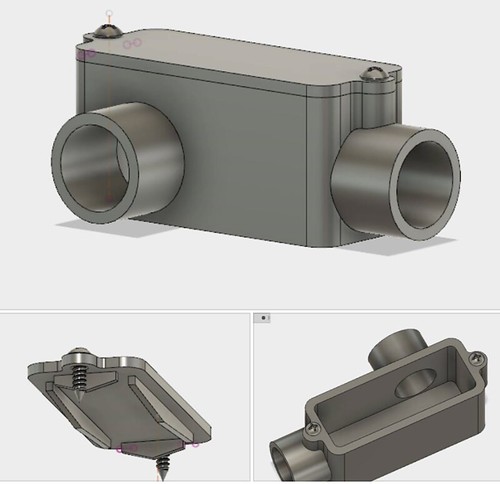

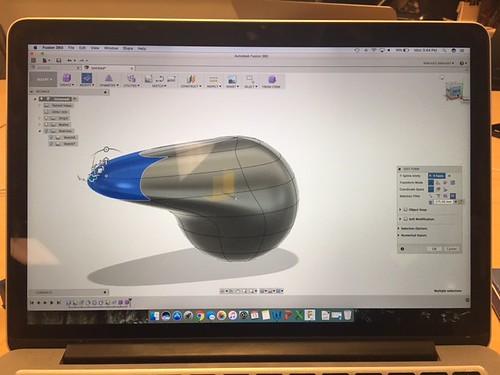

This week, we take a step further into product design by learning how to use Autodesk Fusion 360. Luckily as students, we have free access to Fusion 360, a tool we all found to be quite powerful and intuitive. Prior to our class session we were able to follow a series of tutorials to become familiar with the software, and I was proud to finish this model before class. I really enjoyed playing around with the software while learning its capabilities. In our class session, Jeff Smith, an Instructor from Autodesk presented to us and taught us how to use many of the features of Fusion 360. Following Jeff’s presentation, Dot Silverman came and presented on her work with Biohacking.

As with many software programs, Fusion 360 is a very powerful and complex program. Initially, it can be difficult to navigate and to achieve your desired outcome in design. However, once you become more comfortable with the program, designing can come naturally to you. Playing around with the tools has been really helpful in learning how to properly use the software, and I found the tutorial videos very helpful. I also found this slide deck which gives an overview of how to use many of the tools in Fusion 360. I personally am a big fan of tutorial videos and slide decks as I can go through them many times until I fully understand each step. Something else I have already realized is that there are many design implications to keep in mind when designing for 3D Printing. This article gives a brief overview of mistakes to avoid when designing. Many of these echo what Jeff mentioned we must be mindful of when designing in Fusion 360.

Moving forward in the class, our group is approaching the point at which we will need to start designing on our own. We all need to learn and practice using the design software, 3D printers, and the many other technologies and machines that are available to us. We want to make sure that our design is desirable, viable, and feasible. We need to be sure that our design is logical on the screen and in its physical form, so being comfortable with the design software is paramount to our success.

Unfortunately we did not have much time to cover Biohacking in class, Dot introduced us to the concept of biohacking which could involve anything from product manufacturing to medical uses. This article gives many examples of how makers can “biofabricate” clothes, furniture, and other special materials to turn manufacturing into a more sustainable process. As we continue to evaluate future implications of making and 3D Printing, biohacking will become a major discussion point.

Hi Brian, your models are really impressive! Also, I found the article that talks about the common mistakes in 3D printing helpful as well. Although 3D printing is amazing and can help us achieve a lot of things, it is also a process that has a lot of restrictions. We need to keep in mind that it always builds things from bottom and can not build things in the air. Also, having the proper wall thickness and support is extremely important, especially because the support area and weight of the product doesn’t change proportionally sometime. Again, thank you for posting the useful links!

Hi Brian!

Good job writing the reflection. You have covered everything. The sculpting tool is really interesting as it can actually make things so quickly with such organic looking forms which would generally take hours to make on a regular CAD software. Making it free for students lets students take full advantage of the software and learn more each day.

Brian,

Great Post Overall! I am also trying to learn as much about Fusion 360 as I can, as it is a really cool software that can give you the ability to create just about anything you want. Great Use of pictures, it took me a while to make that conduit pictured at the top of your post, but I know the skills I learn in this class will help me down the road so it makes everything all worth it. I also was disappointed that we did not have a lot of time to discuss biohacking but thank you for that article about it you posted in your blog it was really interesting.

Hi Brian! I really enjoyed your thoughts on the benefits of learning different softwares. It combined week 3’s lesson of design thinking and keeping the consumer in mind with week 4’s software. I really enjoyed the biohacking part of week 4, but I wanted to hear more about it. I did most of my post for week 4 on biohacking. I found a really cool article on vegan cheese. Check it out if you are interested!

Are those your models at the very top? They’re excellent. The fact that you can even portray something as precise as the threads of screws into an object really just shows how powerful Fusion 360 is. It is hard to be intuitive with something like Fusion, even with prior CAD experience, but once you get the hang of things you really can create just about anything your heart desires with it.

Brian,

I think your post is very well written and has some great insights! I really enjoyed the slide deck that you placed inside your post. I took a look at it and really helped me further cultivate my knowledge of Fusion 360. Your model of the conduit is one of the best I’ve seen in the class so far so great job on that too! I struggled alot with that last week and it is awesome how you were able to get the screws on and everything else. I also agree that is was unfortunate we didn’t have more time to talk about biohacking. But I think if you check out AutoDesk’s Pier 9 they definetely have so great innovations possibly involving biohacking going on there! Take a look here!

http://www.autodesk.com/pier-9/workshop/news-updates

Great post overall!

Below is a link to my model I made after class. I devided to make my water bottle because I could incorporate a few different components, a joint, extrusion, hole, revolve, and a few other functions. http://a360.co/2m1WOEh

Here is a photo of the water bottle without the lid. I drew a sketch with different size bases then revolve it around the axis to form a hollow cylinder that widens. https://flic.kr/p/RGCBX7

Here is a photo with the lid with a tread and the straw going through it. https://flic.kr/p/RGCBTQ

Brian,

Great points across the board. I am still in the process of learning how to use Fusion 360, and one thing you mentioned really stood out to me. ” We need to be sure that our design is logical on the screen and in its physical form, so being comfortable with the design software is paramount to our success”. Making sure our design on screen translates to success in the real world is something I am interested to see take place. Making sure the design will be functional in being a solution, is both challenging and significantly important to what I think can make or break a successful project.