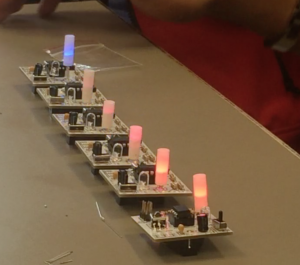

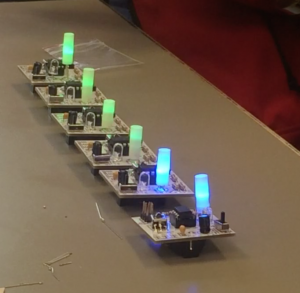

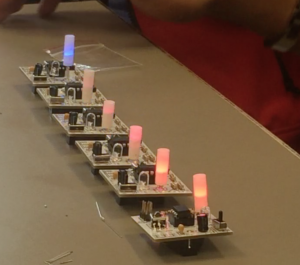

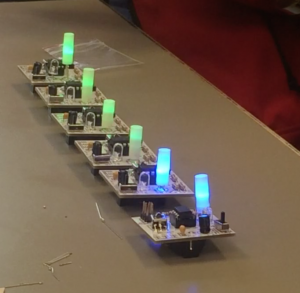

On Monday March 14, 2016 we were graced with the presences of Mitch Altman as he gave us a very insightful workshop on Soldering as we made “Trippy RGB Waves”. He is an alumnus of The University of Illinois Urbana-Champaign and while he attended the University he received both his bachelors and Master’s degrees studying Electrical Engineering. He is one of people that took his passions and hobbies a turned it into a successful business. He owns his own company called Cornfields Electronics. The invention he is most famous for is a little key chain called “TV-B-Gone”. This is just a single button that can turn off any TV. Mitch Despises TV so this was his solution for his own personal use but it turned out to be something that many people wanted therefore he turned it into a major business.

Photo Credit: Lois Holman

TV-B-Gone isn’t all that Mitch Altman is known for, he was a student with quite a wild side. While he attended the University in 1977 he co-foundered “Hash Wednesday” a well-known UIUC holiday back in its day. This holiday is comparable to today’s Unofficial St patty’s something that the students love celebrate here and the University looks down upon tries to use all the preventive tactics they can so the event doesn’t take place. Hash Wednesday was a day where students and kids from miles away would gather on the quad to smoke marijuana. They would all pitched tents, play games like Frisbee, play music with guitars, and even sell t-shirts, And Mitch was behind the entire event.

This link below is a TEDTalk that Mitch Altman spoke at in Brussels, it is about The Hackerspace Movement, but outside of that he also talks about how he reinvented himself so he was someone he like and enjoyed being. It is a great TedTalk and if you wanted to learn more about him definitely take this a few minutes to watch it!

https://www.youtube.com/watch?v=WkiX7R1-kaY

Mitch seems to be a very well rounded person and that was easy to see last Monday, he was very helpful and was constantly making sure we all understood what we were doing throughout the entire workshop to ensure our end products would work as needed. As many of the students in BADM395 didn’t know much about soldering walking into the class period at the end of it many of us were excited to learn more and do more with soldering and Arduinos. The way Mitch helped us understand what we were and why we had to solder the way he told us too really helped us enjoy the workshop even more. Many of the students really only had a theoretical understanding of how to soldering which that had had learned through watching and reading about. This workshop took all of our 2D understandings of Soldering and turned them into a 3D understanding. Here is another video were Mitch talks though how to solder.

https://www.youtube.com/watch?v=RZhR2uQMCSI

Mitch Altman was a great presenter and we were all very excited to have him in class and talk to our class through soldering while we made some trippy LED light waves. If you ever have to opportunity to meet him we high suggest you take the time and just talk to him for 5 minutes.