This week was quite interesting. Contrary to what the title of this post my imply, we were not shooting lasers, we were using them to etch!

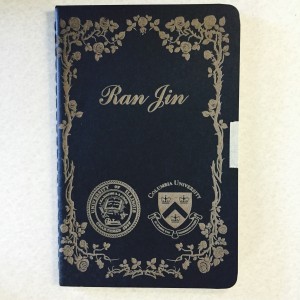

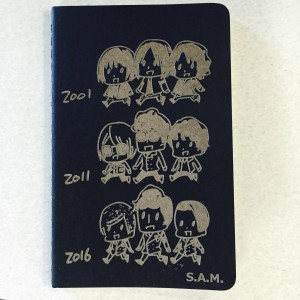

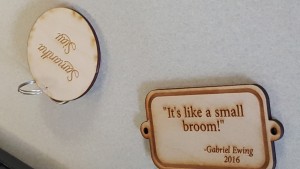

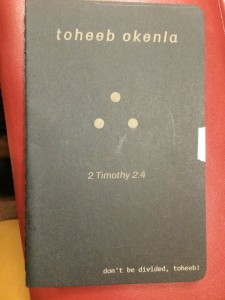

This week, I was in the lasers group and we learned about using lasers to print images. The week was pretty brief, we were able to learn about the lasers and its capabilities and then we were able to use illustrator or a different 3rd party editor to make our images. We learned that the best images that work with the lasers are flat ones with not many gradients. So we were directed to choose silhouettes so that the printing could be easier. I chose to print on a small notebook (below)!

Lasering is really cool because stuff that might take hours and hours of workmanship can be accomplished in a couple minutes. The majority of the work is done on software and the rest the laser handles. I think this can make a lot of design and printing processes much faster

I don’t know if this means much to me, maybe because the work wasn’t really hands on, but I found it really cool though.