Before walking into the MakerLab this past Monday, I needed to get into the right mindset. Specifically, I needed to get into the Maker Mindset. Puns aside, I was absolutely intrigued by Dale Dougherty’s The Maker Mindset. It never dawned on me that I was a part of this so-called “Maker Movement.” By simply taking this class, I have signed up to join this movement, which requires me to forgo conventional methods of ideating and creating.

In class, that is exactly what we did: ideate and create.

However, before we could use the 3D printers to create our ideas, it was required of students to meet with their groups to peruse through various 3D printing-related websites. The two different websites that my team had to explore were Shapeways and MyMiniFactory. Both of these sites shared a common thread, they allowed for makers to share their unique ideas and receive feedback on their products. I got a true sense of community from both Shapeways and MyMiniFactory! Also, I learned of some very cool and useful products that were being shared on these sites.

Although there were a plethora of useful products to choose from, I had to limit myself to four objects that could be used in my everyday life. In no particular order, these products are listed below:

Remote Holder – https://www.myminifactory.com/object/holder-remote-control-10234

Back at home, I have at least 4 different kinds of remotes. Instead of having to waste time looking for a particular remote, it would be nice to have a singular location for all of them. Hence, the remote holder. The design can be customized to fit the varied sizes of the remotes.

Toothbrush Cover – https://www.myminifactory.com/object/toothbrush-cover-9426

If you’re a germaphobe like me, you might want to invest in a toothbrush cover. The thought of using a dirty toothbrush is quite repulsive. The cap can be designed to fit the specific shape of the head of the toothbrush.

Power Cable Clip – https://www.myminifactory.com/object/power-cable-clip-3438

I’m constantly tripping over different cables and wires, so it would be nice to invest in one of these power cable clips. In my apartment, I have quite a few cables that are just laying around. As for changes to this design, I would customize the width to make it appear less bulky.

Selfie Stick – https://www.myminifactory.com/object/selfie-stick-11330

This generation is known as the “selfie” generation, so it is imperative to invest in a selfie stick. The functionality is to take pictures to include more individuals, but the design of this can be changed in a way in which the selfie stick can rotate and extend farther than the average length.

Of course, there were a lot more awesome 3D printed items to choose from, but this is my condensed list of products that I could see myself utilize nearly everyday.

Lastly, as I stated earlier, last Monday’s class purpose was to ideate and create. I chose to add onto my existing collection of key chains. The result was this cute, miniature-sized Android keychain:

Already by week 2 we have begun printing in class! I was very excited about this and didn’t expect it to be so easy. At the beginning of class we formed groups based on our buddies that we’ll be working with for the rest of the semester. My group was assigned to look at the Hyperbolic Planetary Gearset on thingiverse, and explore why it was created/ how it can be remixed. We concluded that it was most likely printed to show how gears can fit into one another and physically represent a model of simple gears. The file had different blueprints contained within it but it did not look difficult to assemble. After this we got to search Thingiverse for different objects and makes, I had no idea how large of a library Thingiverse contained! I decided to print a cover for my toothbrush however all printers were being used so I will do it at the beginning of class tomorrow. I got the blue prints for the make on Thingiverse here and am looking forward to having a customized cover.

After reading “How to Make Almost Anything” and “The Maker Mindset” this week, I wanted to talk about how motivated I was after reading “The Maker Mindset” by Dale Dougherty. The author describes making as once being a “core attribute of the American Middle Class” and how it has changed to no longer being the norm. He describes people who are not making as people who are just waiting to buy and consume and I could not agree more! I almost felt a little bit guilty because I had not thought of everyone being lazy before, however after seeing how easy it is to download Cura and share ideas on Thingiverse, everyone should be adding to it! This was a very eye-opening article for me.

I would without a doubt use this shower head if I ever moved into an apartment or building that needed a replacement one. I chose this object because my older brother recently told me that they do not use the second bathroom in their apartment because they do not have a shower head and do not want to go out and buy one. To change this I think I would learn how to create a knob that would change the size of the holes which could then change the water pressure.

I use a carabiner for all of my different keychains, just because it is easy to keep track of and hook onto things. I found this by searching under some of the most popular makes and it makes a lot of sense that something so practical would be near the top. If I were to remix this make I might add a larger base, so that a phone number could be scratched into the side.

This I believe is one of the examples Professor Sachdev used in class however I wanted to talk about it because I recently had a trip to walgreens this weekend where I wished that I had printed this in class. This item is very practical and is something I would definitely carry in my pocket when I go to the store. A small change I would make would be adding a hole on the side so that this could go on a keychain.

This last object is something I could definitely see on my desk here at school. A smartphone holder is a great idea for someone who’s often playing music on their phone and streaming it to a bluetooth speaker. I would remix this make by adding more material on the base and adding a cutout so that a charger could go under it while the phone was in the stand.

It seems like the Making Movement is all but losing momentum, thanks in part to Millennials like us. According to The Maker Mindset by Dale Dougherty, making is seen as something personal and intimately intrinsic in nature. I would have to agree on this point very much. Week 2 was spent learning Cura, downloading models, and making our first prints. I was really excited that we were able to learn to use the printers so quick; after all, that is what we took this course for, right?

We started class off that day by breaking up into the teams, which we would be in for the rest of the semester, so we could get acquainted. Our first assignment was to look over “Making Websites” such as Thingiverse, YouMagine, and Instructables just to name a few. Our task was to decide what the websites function was, and what field or interest group it best served.

The most difficult part of class that day for me was ironically what was probably supposed to be the easiest: the task of finding something to print. Now, you have to know a little something about me first, in order to appreciate my dilemma fully. I’m a very indecisive person and I am a very thick headed individual. While it took people at most ten minutes, took me easily a half hour. However, I finally settled on something to print. It was a Hollow Celtic Skull.

Reading the weekly article called In the Next Industrial Revolution, Atoms Are the New Bits, I am very surprised to learn a mind-blowing example of the power of micro-factories names Local Motors. It is a very creative business idea to transfer innovative designs into reality. Each design is released under a share-friendly Creative Commons license. The business model is very similar to the websites, such as Thingsverse and Shapeways that we have talked/shared in class. Customers are encouraged to enhance the designs and produce their own components that they can sell to their peers. Seeing the operation and core value of Local Motors in a bigger picture, on the one hand, the cheap explosion and powerful prototyping tools allow more people who are the lack of engineer or design experience to participate into the interesting process. On the other hand, the prototyping approach is able to transfer the current manufacturing from developing countries into domestic with increasingly flexible, Web-centric, and open to custom work. It is great to have a chance to get updates of the current industry as well as combine the learning from my supply chain management class.

Professor Sachdev led us to share some thoughts on different digital making websites. The exploration process not only encouraged me to critique and discover multiple types of designs but also motivated everyone to participate in our own first 3D-printing design. Although I have designed 69 cell phone cases on Thingsverse because of my research project, I have been so excited to print an octopus stand for my IPhone (Check out the pictures). I always want to have a unique holder when I watch videos/movies on my phone. I was tired of seeing the same and tedious designs on EBay and Amazon, so I tried to customize a distinct design. It was a little frustrated in the first half an hour because my printer did not function very well. The object failed three times, even with the help and several machine adjustments from Professor Sachdev and technicians in the lab. I revised my model and canceled brim for platform adhesion in the fourth time. It ran smoothly in the first ten minutes, but then one of the parts was removed by accident. The octopus stand finally worked in the fifth trial. Learning from this activity, I think some downsides of 3D printing should be improved in the future. For example, if the project fails in the progress, people have to restart, which it will be time-consuming for designer and increase material waste.

A simple design is able to make our life easier and save space to keep small pieces organize. Furthermore, it is a good way to place wet toothbrush head without make bathroom table look dirty. The design can be customized depending on different types of the electronic toothbrush and the number of toothbrush heads that you want to keep.

Ethernet Cable Runners provide a simple solution to keep your Ethernet cables neat, under control and easy to access, insert and remove. The range accommodates from 2 to 16 cables depending on your personal needs. Cables can be easily messed up at offices or home, but Ethernet Cable Runners allow bunches on cables to be run along under shelves. Customers are able to choose different version and angles of cable runners. It is a very flexible and cost efficient design.

My Apple cables are prone to breaking at the joint between the connector and cable through use, particularly I bring all my cable in my backpack all the time. Unlike alternative methods available to counteract this problem the Springy Apple Cable Saver does not just transfer the flex / break point away from the cable / connector joint to another point further up the cable. It is a good idea to make our lives better, but there will be some improvements implementing on the design because the holder is too loose. New measurements should be calculated.

This is a very functional and useful design in the household. The “octopus” design helps people distribute drinks conveniently in eight cups. Very simple object but solve a big problem if you want to share drinks with guests. However, the current model applies for eight drinks. It should be customized according to personal preferences or have switched to control the flow.

This week we had the chance to explore various websites for 3D printing and finally print our very first item!

The website my group got was Thingiverse, which is awesome for newbies since it was in ready in print files. We looked at Hyperbolic Planetary Gearset, which is “a visually exciting object which is a practical demonstration of both simple and advanced principles in the design of geared systems.” or basically, a plaything.

This is a really cool design though, consisting of 7 printed parts that had to be put together with screws. The remixed version (where people upgraded the original files) doesn’t require screws which is great.

When it came to our turn to print items, I picked a relatively small one (it printed in less than 20 mins), Cable Holder (Cable Clip), which I resized to 75%, following one of the comments that mentioned that this was too big for iPhone cables. It still turns out a little too big though, so most likely 65-70% would have been the right size.

Since I took videos of the printing with Snapchat i lost the files (forgot to save them!!!), but still!

Dale Dougherty said in “The Maker Mindset”: “While technology has been the spark of the Maker Movement, it has also become a social movement that includes all kinds of making and all kinds of makers, connecting to the past as well as changing how we look at the future.” This is especially true in the Thingiverse website, where all sorts of items can be found. That said, here are 4 functional items form Thingiverse that I would definitely print sometime in the future.

Since I have so many cables running around my room, I figured this would come in handy. I would probably customize this to the thickness of my table (since it’s a glass piece and not a thick slice of wood), and my dresser.

Mini Tape Gun – Tape Dispenser

This looks awesome! I would most likely enlarge this until it’s the size of masking tapes though, since i always have trouble tearing strips of it when I am shifting houses.

These are always handy, since everyone brushes their teeth (or I’m sure most do). No more squeezing the paste up for it to slide down again!

UBO – The Universal Bottle Opener

Trouble opening bottles? No worries, here’s the universal bottle opener! I’ve always relied on my apartment mates to open jam jars for me, so this would be a welcome addition!

This past class was my first time making something of my own with the 3D printers! I feel like a majority of people made something of actual use to them, But I just wanted to make something fun as my first print (my Shiba Inu). Basically, from this past class I learned how simple it actually is for a novice like me to be able download something off of the numerous available sites and print it within half an hour.

While we were printing, I thought about how Dale Dougherty of The Maker Mindset claimed “Students are seeking to direct their own education lives, looking to engage in creative and stimulating experiences. Many understand the difference between the pain of education and the pleasure of real learning.” I felt that this class is what he meant, in the sense that a lot of us come from very different studies at this university and all had varying reasons for why we took this course. But a common theme was that we all wanted to explore creatively, and through this nontraditional course we can take our new-found knowledge and expand upon it in our own fields. This course allows us to explore ideas creatively, have actual hands-on experience, and really enjoy “the pleasure of real learning.”

Searching among the different printing websites, the first thing I found for everyday use is an Elephant Envelope Holder from Pinshape:

As a student, I feel like I always have random papers, folders, and envelopes floating around. This cute holder would help me keep my documents organized. To adjust it more for my life, I would include separators in between the two ends, to even further organize between certain documents.

As a student, I feel like I always have random papers, folders, and envelopes floating around. This cute holder would help me keep my documents organized. To adjust it more for my life, I would include separators in between the two ends, to even further organize between certain documents.

Another product I found on Thingiverse that would be really beneficial to my life is this GoPro Steadying Stand:

I love using my GoPro whenever I travel, and sometimes shots or video can get ruined because of accidentally fumbling or not resting it on a steady-enough surface. To make this more suitable for my life, I think I would change it so that it was more of a tripod mount, as opposed to the two pillared sides. But if that’s how it stays steady then okay!

I love using my GoPro whenever I travel, and sometimes shots or video can get ruined because of accidentally fumbling or not resting it on a steady-enough surface. To make this more suitable for my life, I think I would change it so that it was more of a tripod mount, as opposed to the two pillared sides. But if that’s how it stays steady then okay!

From Shapeways, I found this really cool instant-vase creator:

I love displaying flowers, and this little instant vase creator would allow me to turn any household glass into a vase. Obviously I would need to adjust the diameter of the larger end to fit the glasses I already own, but I think that would be worth it instead of having to spend the money on the vase to fit the flowers.

I love displaying flowers, and this little instant vase creator would allow me to turn any household glass into a vase. Obviously I would need to adjust the diameter of the larger end to fit the glasses I already own, but I think that would be worth it instead of having to spend the money on the vase to fit the flowers.

Lastly, from Shapeways I found this really handy Finger Armor:

I frequently chop up my veggies almost every night for dinner, and this would be extremely helpful! Except this picture doesn’t look like it accurately depicts how to chop vegetables. A lot of the time I only use my thumb and index finger, so I wonder if it’s possible to make one just for those fingers? Or modify the shape in which you hold different vegetables.

I frequently chop up my veggies almost every night for dinner, and this would be extremely helpful! Except this picture doesn’t look like it accurately depicts how to chop vegetables. A lot of the time I only use my thumb and index finger, so I wonder if it’s possible to make one just for those fingers? Or modify the shape in which you hold different vegetables.

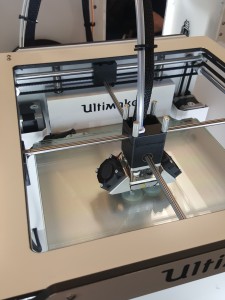

I finally did some actual making! This week was awesome as we got some hands-on action with the Ultimaker 2s! But before we get to what I made, how about a little about what I learned. We got to assigned to teams of a couple people and were able to browse assigned websites to see what they were about. Our team got to check out YouMagine and Instructables.

YouMagine

YouMagine is a website where makers get to collaborate on 3d designs. It is essentially a 3d design and file sharing platform created by Ultimaker (sound familiar?). It is essentially designed to be the Github of printing. You are able to make and push your ideas, designs, and work unto the site in which people can then use and build upon. Outside of the fancy aesthetics of, I thought that the site is an amazing idea. If we can have an open source platform for software, what not for 3dware?

Instructables

The second site we were able to visit was Instructables. Instructables is essentially a site with instructions on how to make everything there is to make in the scope of 3d printing and small electronics. Very intrigued searched how to make a drone and lo and behold there popped up many results with detailed instructions on how to make a drone with 3d. This sparked some interesting drone conversations that even crept its way into one of Professor Vishal’s talks.

Browsing these two websites really made a couple things clear to me. One thing is that there is a huge community of Makers out there and they are making cool stuff! I can agree with the Dougherty reading’s description of what a maker is, there are just people looking to create or recreate things in new, renewed, and even unorthodox ways. Dougherty states that “makers are seeking an alternative to being regarded as consumers, rejecting the idea that you are defined by what you buy” and this is made clear in the sites we visited. I mean how could this be more represented by having “consumer” essentially take on the role of designers and manufacturer; merely consumers no more!

Another thing made clear by this site is that being a Maker is likely to be the next norm. I support this statement with our Gershenfeld reading. Gershenfeld understood that there is an absolute parallel between computing and digital fabrication, “As it turns out, the “killer app” in digital fabrication, as in computing, is personalization, producing products for a market of one person.” We all know how personalization in computing changed everything! I think that printing has that same potential.

Class activity!

Finally to what I made in class. I was able to use the Ultimaker to print myself a iPhone 6 Plus phone case! Also below are shots of the action that went on.

4 things!

drone, because it’s awesome to fly those things! however, I would love to have a where to make it so that it would be safe indoors.

iPhone case, I think this is explained above. It seems to be a bit loose though, so I would make it fit more snuggly.

shark comb, because I have long hair. I would make prongs wider and longer!

teddy, because it’s cute! If it was possible to make this cuter, I would. Doubt it, though.