We all come form different backgrounds and experiences, some of us with the knowledge of using software’s to build parts and others with absolutely no experience. Regardless of which skill level we were at we all were able to takeaway a life long learning experience from Jeff Smith, an individual from AutoDesk that had come to teach us the ins and outs of Fusion 360. We all were inspired by Jeff’s story of reaching his current position at AutoDesk. Even though he had many shining moments he had also faced many struggles. In the end, the struggles he faced had helped him identify the connections he had unknowingly built. Putting together his network and his strong skills he began to learn Fusion 360 in order to empower college students to innovate with the software. Because many commercial companies would like the future generation to be able to maneuver through the software skillfully in order to help the company, they require AutoDesk to provide these lessons for college students. As college students, learning Fusion 360 is an added skill that will only bring us more benefits in our careers.

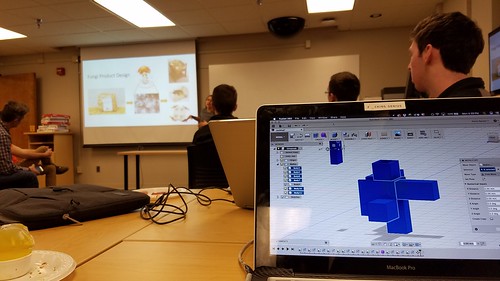

Throughout the class period Jeff had given us a live tutorial of Fusion 360 while allowing us to have hands-on experience with the software throughout each step of the tutorial. Specifically he wanted us to learn the tools and functions of the software so we would be able to continue creating in the future. Fusion 360 essentially is creating designs digitally and immediately transforming them into real life products. Prior to the class we were all given the task of using introductory videos to learn the tools of Fusion 360, a few of us were able to create the final model from the video while many of us had slowly trudged through the process of creating the model while continuously honing our skills in the new software. The process of learning was well stated by Veronika, “Diving into Fusion 360 during this weeks class session was like jumping into the deep end of the swimming pool in an attempt to learn to swim; needless to say, there was initially quite a bit of floundering.”

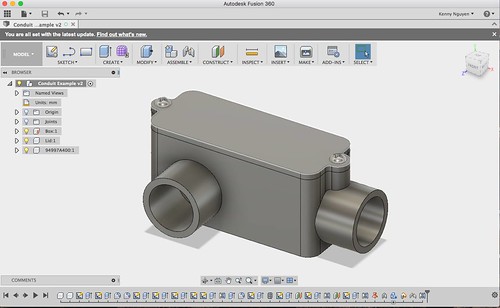

Many of the students were amazed with this CAD software, as it was a popular one with very powerful tools. As stated by Jorge, “One thing that makes Fusion 360 such a great CAD program is the whole cloud system they are using…” We all realized that with the software any innovation was possible. We had the ability to design through parametric designing, which included specific constraints and dimensions and free-form designing or sculpting through the Tee-Spline Body. Taofik was intrigued with the software, “They use a top-down componentry/modeling system system unlike other CAD software such as Creo Parametric or SolidWorks which use bottom-down modeling. You could even type code and create a model instead of clicking around the tools.” We were all amazed that the software gave its recommendations of the innovations that were created, a new and powerful concept we had not experienced before, the software had the ability to teach us efficiency on a design.

After learning the tools of the software we were given the task to create any everyday object by taking apart the object and building it on Fusion 360. As Ian had commented, “I think throughout the workshop I realized just how much I took for granted simple engineering feats. Taking a simple water bottle the shape itself is complex enough but it actually has several parts working together to provide us with a coherent product experience. Without great designers with software like Fusion 360 we wouldn’t have most of the products in our world today.” The realization of the importance of designers and new creations in the world suddenly seemed so relevant. If we wanted to create products for this world, we needed to continue honing our skills in this software so we could build more innovative and efficient products for future consumers.

Here are some of the models that students had created after taking apart everyday products and rebuilding them on Fusion 360:

Chase had created a water bottle and found that, “The most difficult part of the design was instructing the software as to what parts were components, bodies, joinings, cuttings, etc. Albeit at first it was frustrating, I gradually began to understand how the software functions.”

Kenny had also created a reusable water bottle and commented that, “Every aspect of every object you use has been analyzed and reiterated until it was ready for consumer markets. This means that there are elements of design everywhere in everyday objects and this exercise gave me the insight to develop a product for the class.”

Jorge, who had experience in inventing throughout high school was able to create an intricate model of a flash drive.

Overall, the workshops had created a large spark for each of us and had allowed our creative juices to begin flowing. We all believe that capitalizing on all that the program has to offer will create tremendous results. This CAD software, Fusion 360 allows any individual to create whatever their mind thinks of and that in itself is revolutionary. It is true; Fusion 360 truly has no boundary for future innovation and design.