This week at the Fab Lab, I dabbled in using Arduinos. Having never coded before in my life, using an Arduino came as a bit of a challenge. We started out using a basic Blink code, which caused a light on the Arduino to blink. Using the code, we were able to change the code so the light would pulse faster or slower depending on the numbers we inputted.

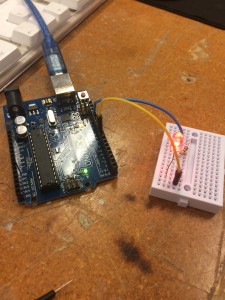

After completing this, we expanded on the concept through wiring our Arduino up to an LED, so this time the code corresponded to the LED light. After, I found a code online to make the LED fade in and out. Wanting to test my new knowledge of coding, I attempted to combine the Blink and Fade codes, which ended up failing. I still found other ways to play around with what I learned, however, such as by hooking up a second LED to the Arduino and modifying the code so that the two LED’s flashed at different times.

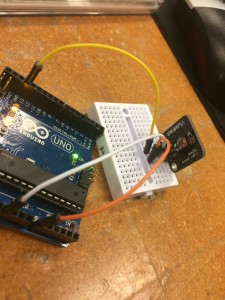

After playing around with LED’s, we were given light sensors to play with. With the code associated with them, they were able to pick up on data about how much light was around them. We then also had an LED hooked up and found an “if” function online so that when the light it sensed was above a certain level, the light turned on. We then reversed this code to program the light to be like an automatic nightlight so that when the light was below a certain reading the light would turn on.

Although coding probably is not my thing, learning about it made me realize that anyone now has the capability to add innovation to society. There are a lot of people with highly creative abilities who are now able to make their ideas reality because of the ability to just copy and paste codes from online.