I remember when I first saw the Digital Making Seminar course flyer, I imagined this course would be radically different than courses I had taken in the past. Now that I am writing my semester’s reflection, I can safely say that this course greatly surpassed my expectations. I did not simply learn in this course; this course transformed the way that I think.

The Maker Movement and Learning to Become a Maker

When I first heard about the Maker Movement, I was fascinated because I have always had great interest in exploring ways that people can learn most optimally. Professor Kylie Peppler from Indiana University spoke to us at the beginning of the semester in great detail regarding the Maker Movement and I was inspired to truly understand what ‘making’ could mean in my own learning experience. This course gave me the opportunity to experience firsthand what it means to learn by making and how tangibly creating something can challenge your mind in ways that traditional teaching methods simply can’t. By getting to experience a workshop put on by Design for America, I saw just how significant this movement was and that I was sitting at the forefront of it. Not every student gets the change to take a course like this, so being able to witness testimonies from many guest speakers throughout the semester showed me just how significant this whole ‘making’ ordeal really is.

Moving forward, the importance of the Maker Movement and everything I’ve learned about making digitally has motivated me to be involved with this community and continue expanding my knowledge in the areas of disruptive making technology. I have most formally pursued this by taking on employment at the MakerLab! I began working here very recently and I could not be more excited to continue being immersed in a place where I’ve learned that creativity and innovation are the fuel to the continuing technological development of society.

Technology and All The Ways I Learned to Make

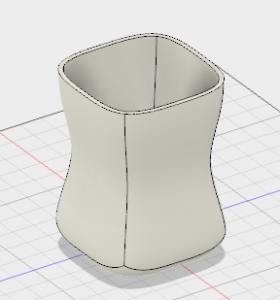

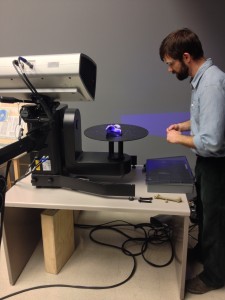

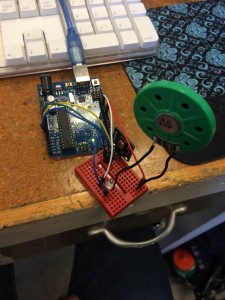

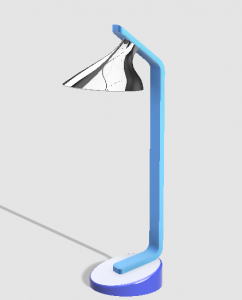

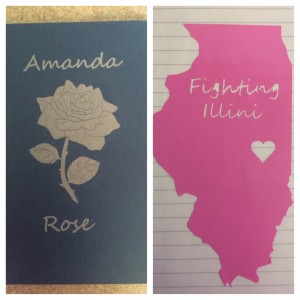

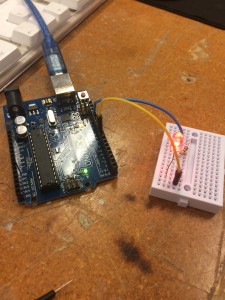

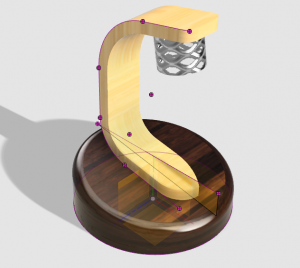

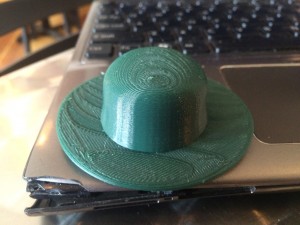

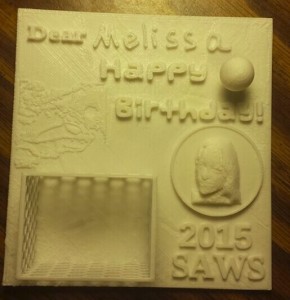

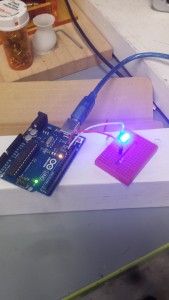

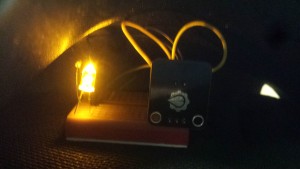

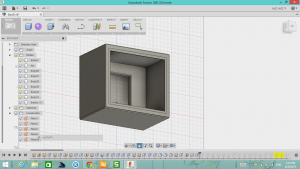

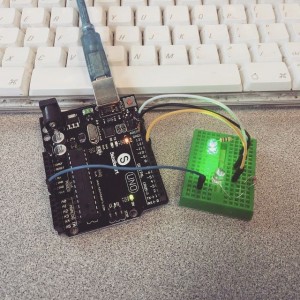

This semester, our class was exposed to a myriad of different tools and technologies that become our instruments for making. From our sessions at the Champaign Fab Lab to our field trip to the Beckman Institute for Advanced Science & Technology, I feel like I discovered so many different ways to create things that I did not even know existed. Some of my personal favorites were learning how to digitally embroider and create objects in Fusion 360. I think what I enjoyed most about creating through these mediums was my ability to allow my thoughts to flow freely from one to the next. One of the biggest takeaways I have from learning how to tinker with things like arduinos and different softwares is that the digital making space is not a confining one. I am able to create something digitally and do 1 million+ things to it on a variety of different platforms. Digital making allows us to bring ideas to fruition in ways that were not possible before and simply because of that, I can see that this course brought me immense value.

One of the aspects that I loved about this course was also learning that the technologies we used can be leveraged for so many different uses, including ones that many people may never even have thought about. For example, I am involved in different religious communities and I was so pleased to find that I could leverage our digital making platforms to create things that I could use in the realm of my faith. A religious application is probably one of the last things people would think of when talking about things like 3D printers or digital embroidery, but the endless possibilities of digital making are what makes it so incredible!

Digital Making is Whimsical, Unpredictable, and an Unending Exploration

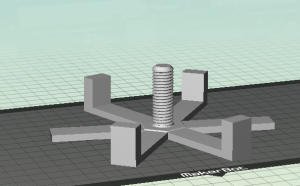

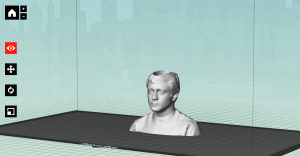

I also have to note that while I intentionally made some pretty cool stuff, I also ended up accidentally creating things. I tried to print a grocery-bag hanger that was formulated from the base of a bolt and I also tried to print a digital scan of myself as a shot glass. Neither print accomplished the purposes of what I had for them individually, but together I created an interesting art piece! The grocery-bag-bolt-hanger spins in the hole I created in the digital scan of myself. This to me, represents the beauty of digital making: even when you think you’re done, you’re probably not!

This course has taught me that a singular object can be viewed from multiple perspectives, which consequently derive multiple purposes for the object. I firmly believe that this is an important way of thinking that our generation needs to develop in order to become leaders within the global economy. By exploring concepts in something like Digital Making, we learn how to be empathetic, dynamic, and technically capable leaders capable of succeeding on any terrain. For this reason alone, I could not be more grateful to have taken this class and I am extremely excited for all the ways that my experiences in this class will enable me to help others see the value in creating digitally.

on programs like SolidWorks. After really playing with it, I found myself telling more and more of my classmates in the industrial design program how great Fusion was (as we all had to suffer through learning SolidWorks this semester) and I picked up a huge interest in creating a program to teach newcomers how to use Fusion.

on programs like SolidWorks. After really playing with it, I found myself telling more and more of my classmates in the industrial design program how great Fusion was (as we all had to suffer through learning SolidWorks this semester) and I picked up a huge interest in creating a program to teach newcomers how to use Fusion.

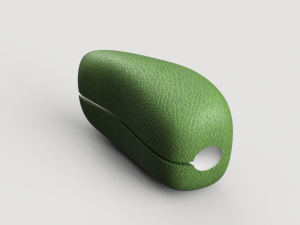

s the use of basic tools, and highlights the organic capacity of the program. In the end, they’d be able to print their creation, add a loop to the top, and put their bears on a keychain. If this proves to be a success, I would love to go forth next year and continue to develop the workshop for students coming into the MakerLab.

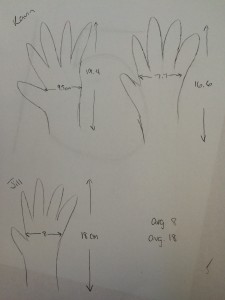

s the use of basic tools, and highlights the organic capacity of the program. In the end, they’d be able to print their creation, add a loop to the top, and put their bears on a keychain. If this proves to be a success, I would love to go forth next year and continue to develop the workshop for students coming into the MakerLab. course was to ideate something new and learn our resources to create it. We teamed up with the FabLab to make a bean that would improve grip in the elderly, and those affected with Parkinsons or tremors.

course was to ideate something new and learn our resources to create it. We teamed up with the FabLab to make a bean that would improve grip in the elderly, and those affected with Parkinsons or tremors. from body-building for the materials used in the bean. This experience in itself was a massive lesson on product creation and everything in between and that’s extremely applicable to what I intend to do with my career.

from body-building for the materials used in the bean. This experience in itself was a massive lesson on product creation and everything in between and that’s extremely applicable to what I intend to do with my career.

resources and what he didn’t know, he worked hard to find out for us and point us in the right direction. There were tons of laughs and frustrations, but all of us came together to create some pretty cool stuff.

resources and what he didn’t know, he worked hard to find out for us and point us in the right direction. There were tons of laughs and frustrations, but all of us came together to create some pretty cool stuff.