This past week we had Arielle Rausin teach us the basics of 3D scanning! The class got a chance to mess around with the 3D scanner to scan their heads. Unfortunately, Team JJJ Inc. has no use for a 3D scanner, at least not for this first prototype.

Our project is coming along. Slowly, but surely. This past week, we focused on making sure our rack and pinion had even better/more precise dimensions. However, even with the better dimensions, I don’t think we will be able to get the light switch to flip with the rack and pinion idea. We might have to modify it a bit to get more torque out of our servo motor. Through some research, we also noted that a normal RC motor won’t work since it’ll be extremely hard to get the motor to turn only a certain degree. This leaves us with only a servo motor. The only problem with this though is that the servo motor might not be strong enough to flip the light switch. My goal for tomorrow’s class is to get a working prototype that actually flips the light switch.

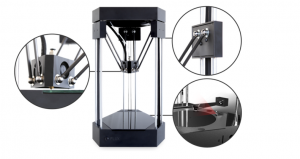

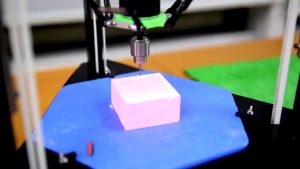

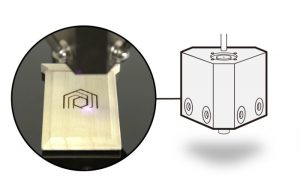

For those interested in possibly buying a 3D printer for your own use, check out this 3D printer that comes with multiple functionalities. When I first saw this printer, I wanted to get it. I still want to get it but I currently don’t have the funds. The very basic printer (only for 3D printing) costs $699. The Delux package that comes with a laser engraver, blade module (for precise cutting) and a holder module (for putting a pen/pencil and having it write on paper). This printer also has the capability of 3D scanning. Here are some pictures of the printer.