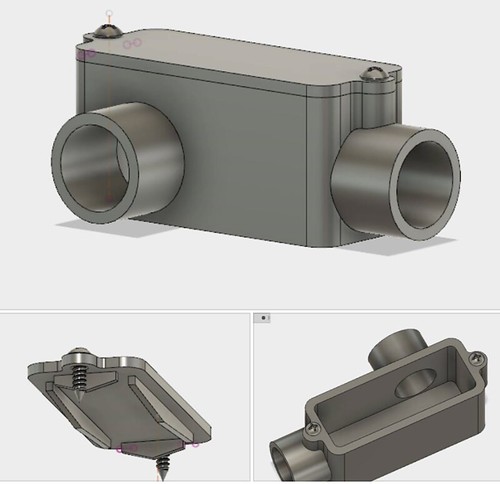

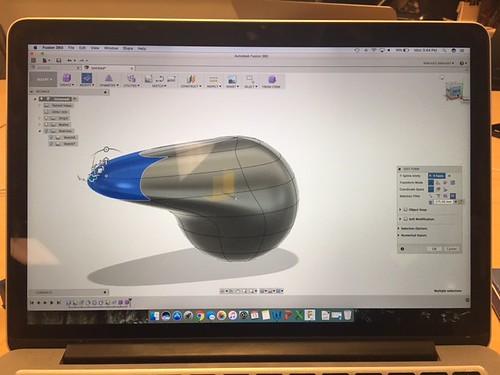

This week, we take a step further into product design by learning how to use Autodesk Fusion 360. Luckily as students, we have free access to Fusion 360, a tool we all found to be quite powerful and intuitive. Prior to our class session we were able to follow a series of tutorials to become familiar with the software, and I was proud to finish this model before class. I really enjoyed playing around with the software while learning its capabilities. In our class session, Jeff Smith, an Instructor from Autodesk presented to us and taught us how to use many of the features of Fusion 360. Following Jeff’s presentation, Dot Silverman came and presented on her work with Biohacking.

As with many software programs, Fusion 360 is a very powerful and complex program. Initially, it can be difficult to navigate and to achieve your desired outcome in design. However, once you become more comfortable with the program, designing can come naturally to you. Playing around with the tools has been really helpful in learning how to properly use the software, and I found the tutorial videos very helpful. I also found this slide deck which gives an overview of how to use many of the tools in Fusion 360. I personally am a big fan of tutorial videos and slide decks as I can go through them many times until I fully understand each step. Something else I have already realized is that there are many design implications to keep in mind when designing for 3D Printing. This article gives a brief overview of mistakes to avoid when designing. Many of these echo what Jeff mentioned we must be mindful of when designing in Fusion 360.

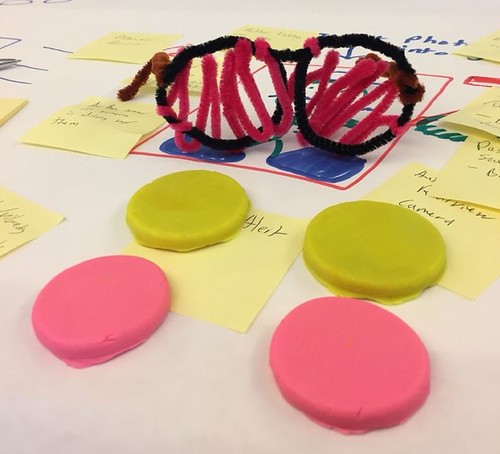

Moving forward in the class, our group is approaching the point at which we will need to start designing on our own. We all need to learn and practice using the design software, 3D printers, and the many other technologies and machines that are available to us. We want to make sure that our design is desirable, viable, and feasible. We need to be sure that our design is logical on the screen and in its physical form, so being comfortable with the design software is paramount to our success.

Unfortunately we did not have much time to cover Biohacking in class, Dot introduced us to the concept of biohacking which could involve anything from product manufacturing to medical uses. This article gives many examples of how makers can “biofabricate” clothes, furniture, and other special materials to turn manufacturing into a more sustainable process. As we continue to evaluate future implications of making and 3D Printing, biohacking will become a major discussion point.