This week we returned to the MakerLab after a three-part tutorial series at the Champaign-Urbana Fab Lab. Before continuing work on our final semester projects, Arielle stopped by again and instructed us on how to effectively utilize a 3D scanner. This technology, she explained, helped her tremendously with making changes to the wheelchair glove that she has been making. Essentially, 3D scanners utilize lasers to scan every part of an object, which is then overlayed together by scanning software to create a 3D model. One software that was spotlighted during the workshop was yet another Autodesk product called Meshmixer, a relatively easy-to-use scanning software that allows the user to edit the scanned model before exporting the file to be 3D printed or added to other parts. Common types of editing include smoothing out certain areas of the model, extruding sides, or cropping unnecessary parts of the scan.

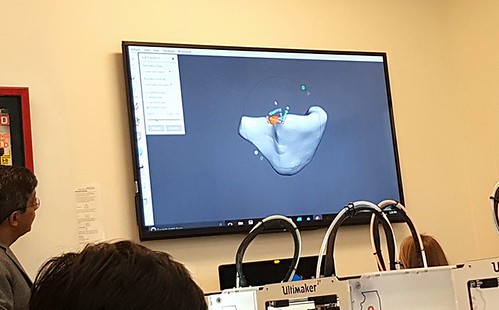

Arielle explaining one of the intricacies of Meshmixer as it pertains to her product:

After her presentation, we were allowed to try our own hand at 3D scanning using a mobile scanner. While Arielle made the process look painless, we quickly encountered a variety of challenges when attempting to scan our objects (our own heads). Firstly, the scanner struggled to pick up certain complex features of the face, such as specific details of the eyes and ears. Next, the scanner required very strong lighting, as the lasers it employed required light to bounce off the object, similar to a camera. This led to another hurdle; any users wearing dark clothing, such as a black jacket or shirt, struggled to obtain an accurate scan below their neckline. As with many obstacles faced throughout the course, over time and with much practice we were able to overcome these complications. Once scanned, we first cropped unnecessary features from the scan and solidified aspects of the object that were not properly scanned. From there, we imported the solidified 3D model busts into Cura to finalize before being printed.

An example of Peter’s bust after being exported into Cura:

For reference, here’s a simple and quick tutorial on Autodesk’s Meshmixer:

After taking a shot at 3D scanning, we returned to focus on our group projects. Our group, Team MakerLax, was able to create the initial model of our product using both Autodesk’s Fusion 360 and TinkerCAD. This first prototype certainly leaves much to be desired as there are a variety of adjustments to be made, however I am glad we were able to design a preliminary model. This way, we understand the direction that we are headed in and can add or subtract features accordingly. I look forward to adding a few more features to the product this upcoming week.

The initial prototype of our “Tie Helper”: