Flexibility. Throughout the entirety of the course, we have discussed how vital this mindset is to 3D making, and creating as a whole. Although it is easy to self-describe as agile and open to change, our group’s true flexibility was put to the test over the past two weeks as it became apparent that our original product and design were not viable for the purposes of this project. And thus, after weeks of brainstorming and continually redefining our version of a trash compactor, we scrapped the entire concept, and began to design a new take on a door prop (a product inspired by the auto-locking doors on our classroom, which have resulted in many lock-outs during class time.)

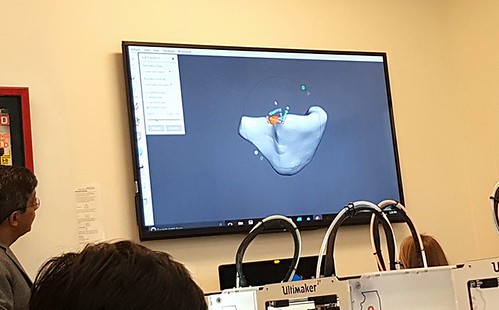

During the first portion of class, we were exposed to the capabilities of 3D scanning, as demonstrated by Arielle and Meshmixer software. This software proved extremely useful for duplicating and tweaking complex designs that would otherwise be difficult to recreate. As we began to consider the requirements of our particular product, we decided that we would not need to utilize this, as our product will have a simple, geometric design that will prove relatively simple to recreate from scratch. However, learning about this particular technology truly sparked my interest with regard to the real-world applications of such a product. Upon further research, I discovered that there are immense forensic implications of these developments, including a fascinating article about the use of 3D scanning technologies to examine a sunken vessel in British Columbia and determine the cause of the wreck. Furthermore, Microsoft has begun developing a mobile application that will allow users to quickly scan and export images of items, the usages of which will range from functional business purposes to amateur artistic endeavors.

The real-world implications of being able to scan an item, create a digitized replica of it, and then alter that replica before printing it back into a 3D, physical representation are going to be widespread and life-changing. Throughout the course of the class, I have taken especial interest in the medical implications of the technologies we explore, and recently wrote an individual piece about recent medical advances in the realm of 3D printing. I believe that advanced 3D scanning abilities will further the abilities of doctors and other medical professionals in their research and solutions. This is just a small slice of the wide reaching implications; I truly believe this technology will forever change the world we live in.