For our second visit to the Fab Lab, each group switched stations to work on a different portion of our final project. This week, I attended the Laser Cutting session. Though the workshop is somewhat secluded towards the back of the Fab Lab, it certainly shines through as one of the more unique creative processes the Fab Lab has to offer (no pun intended).

In my last workshop, we focused on designing the physical circuit for our light-sensitive boxes. This week, we continued with moe hands-on work dedicated to making the appearance of the project aesthetic and to our liking. By using specifically designed software, we were able to create layouts for our boxes that we could customize. We first gained the template after entering our desired dimensions into an online resource, and then imported that file onto the lab computer software Inkscape to customize them. We were able to select images online to use as stencils for the panels. The images had to be completely black & white, as well as properly pixelated. The laser cutters are incredibly precise, and are able to stencil out wood portions with cuts of down to .001 m in width, resulting in flawlessly fitting pieces and stellar quality of silhouettes. One of the most amazing bits of all this, is that each person’s cuts only took approximately 20 minutes maximum, way faster than a conventional 3D printer. While it is certainly a sight to see something create out of nothing, some don’t realize that you can also achieve great designs by taking away from what you already have.

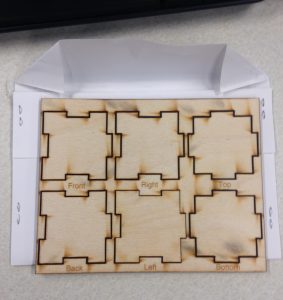

Smaller scale sample box pieces

Smaller scale sample box pieces

For my custom designs, I chose each side to represent a field of engineering/design as I am an engineering major. Four sides included images reminiscent of electrical, mechanical, and computer engineering, as well as architecture. The underside of the box features a 3D printer silhouette as well as that of a laser cutter, the two main methods of design that my group will probably use in our final project. The remaining side just has my name with a special measurement system composed of a ruler image and different sized stars to represent the brightness of the LEDs.

My pieces

My pieces

Sneak peek of the completed project

Sneak peek of the completed project

Now that I’ve completed both the physical portions of the workshop, I’m excited to take part in the coding session next week, where we will program the Arduino with the desired code to allow it to respond as we want it to. I’ve thoroughly enjoyed these Fab Lab sessions not only because we get to create a custom project for ourselves to keep in the end, but we also get to see multiple types of engineering and designing intertwined (specifically electronics, mechanics, and programming) into a single project. It’s been a fantastic experience to work with all these different processes, and I’m hoping that we can incorporate every one of them into our final project.

Hi Brian,

Great post, and thanks for sharing your experiences at the Fab Lab. Laser cutting seems to be an incredibly useful asset to makers and graphic designers alike. While 3D printing is an additive manufacturing process, laser cutting, being a subtractive process, brings a whole different set of opportunities to innovate. You mentioned that you are looking forward to the coding part of this series and using the Arduino open-source software platform; as someone who has already participated in that portion of the project, I can attest to its usefulness. Arduino offers endless opportunities while maintaining a simplicity that allows even makers with only basic coding knowledge to succeed. Again, great post!