This week we got the privilege of having an expert, Jeff Smith, come in and teach us how to use one of the most powerful CAD programs out there, Fusion 360. He structured the learning session by teaching us a lot of tools all at once, and then having us build on our own and seeing what we could create. It was really a privilege to have Jeff come in, and it amazed me the things that 3D printing was capable of doing. One of the things that really stood out to me was the sculpting mode of Fusion, where one could use several features to create complex objects that would take hours to create in normal CAD programs. Best of all, the creator of Fusion 360, Autodesk, offers the program as well as various others for free to students.

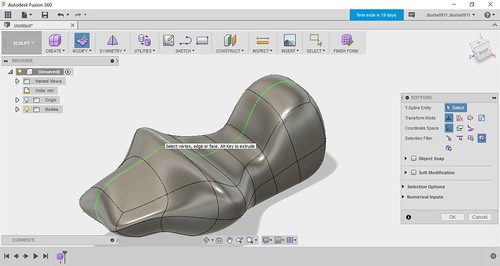

A design like the one picture above could take hours with standard CAD software, but only took several minutes for me to create on Fusion.

This experience was truly awesome because our class got to learn the true power and potential of Fusion 360. Complex designs and parts that would normally take hours to create or modify now can be done with several clicks of a button. This is especially helpful in the world of 3D printing, where there is no need to worry about typical manufacturing constraints such as the increase in cost with an increase in complexity. CAD software like this will lead the charge in the 3D revolution as much as the actual 3D printers will. As Jeff Smith said when he talked to us, “without CAD these 3D printers are just paperweights, and without 3D printers, these CAD designs are just stuck on a screen.” The development of each is important to the advancement of 3D printing and I know I will be keeping close track of developments in each field in the future. The fact that this revolutionary software is offered free for students is also awesome, as the future of 3D printing lies in our generation, and the more young students who have access to the software, the better.

Now that I have learned the basics of Fusion 360, I will continue to play around with it at home, as well as continue to learn how to use it in this class. Jeff will be coming back later in the semester to teach us more advanced Fusion concepts, and I am very excited to see what he has in store for us next time. If you’re interested in Fusion 360, click here for a video that further explains what Fusion 360 does.

If you’ve read this and are interested in learning Fusion 360, then there are some awesome YouTube tutorials found in the links below. I have also added the link for downloading the Fusion software as well.