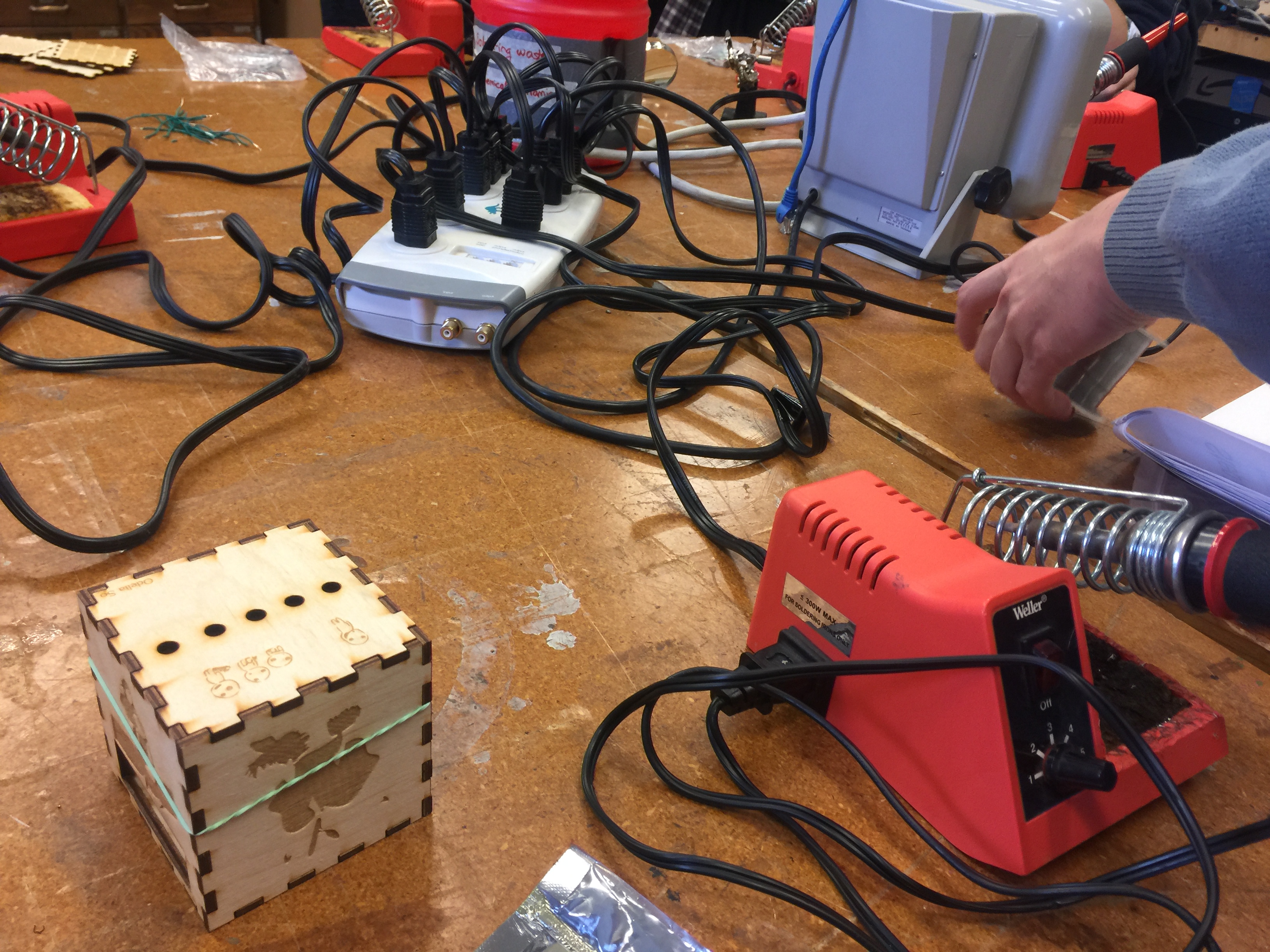

This week at the FabLab we wrapped up the workshop sessions. My team, the white team did soldering this week. Before this week’s workshop, I’ve seen my dad solder wires together to improve “circulation” of the wires, so I already felt like I did have some knowledge in this area. However, in truth, this week was my first week in getting hands-on experience with it.

To be totally honest, out of all three workshop stations, my favorite was the laser cutting station due to my overall familiarity with the concepts of the machine, as well as the usage of the software. This week’s station was probably the most frustrating and difficult area for me. The combination of needing nimble, yet sturdy fingers to twist the wires together, the potent smell of the metals melting together, as well as the fragile and easily breakable wires made the whole process mentally straining. The constant need to be mindful of the positive and negatives of the LED lights, as well as the much-needed patience really took a toll on my attitude towards soldering, and by the end, I felt ready to give up and never touch soldering again. To add fuel to the fire, because of my twisting and turning of the wires, the connections constantly broke to a point in which some of the connections were unrepairable. Because of this turn of events, I was unable to successfully created the LED box that included the soldering of the lights and photoreceptors. Since I broke most of my connections toward the end of the class, I had no time to redo the soldering and was forced to create a prototype LED box with the breadbox and the Arduino. As much as I don’t like soldering, this skill is very important to have knowledge of. Thanks to CUC FabLab, I am now able to solder wires together (even if I’m terrible at it).

In the end, no matter how must frustration or hatred I had for a specific “step,” the workshops that we learned from were definitely really helpful in our group projects and will help us start finalizing what process and skills are needed for the project. Furthermore, not only did we gain three new skill sets to use but also gained insight to our abilities in each skill. By analyzing these interactions, we were able to tell which part of building our future project prototypes was our strong point and which was our weak point. For me, it was obvious that designing and laser cutting was my strong suit, while soldering was hands-down my weak suit.