This week we started building models with Fusion 360. Fusion 360 is a cloud-based CAD/CAM design software developed by Audtodesk. It is a powerful tool for designers from all levels. During the class, we’ve explored a variety of functions in Fusion 360 with instructor from Autodesk. Fusion 360 provide multiple modeling forms, including freeform modeling, solid modeling, and parametric modeling. It also integrated simulations that allow designers to test the capabilities of the models. Besides, Fusion 360 is a cloud-based software that support a high-level of collaboration between designers. As we’ve discussed last week, collaboration is an essential part of human centric design process, and Fusion 360 is helping designers to work together in the second and third phases of design thinking processes.

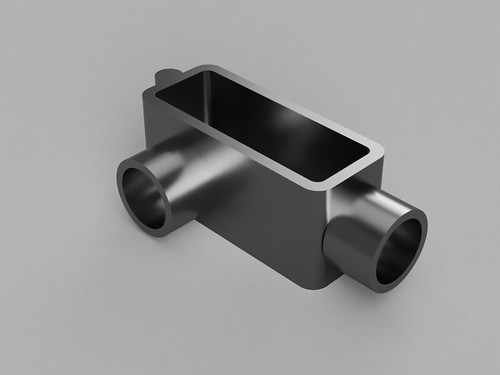

Before the class, I’ve followed the tutorial and built a model for a part of a tool. What I found to be really interesting is how Fusion360 build 3D models based off flat graphs. The only design software that I ever used in the past is TinkerCad, which basically had all 3D figures prepared for users. Another feature that I think it’s really cool but not able to master is the design timeline. Based on the tutorial, designers can save a lot of trouble going back and forward adjusting the models by manipulate the timeline. However, I do believe it requires a certain level of understanding.

After the class, I build a model based off a hand cream. I thought the tube is hard to depict using traditional 2D method, so it may be a good illustration of the function of Fusion360.

I dissected model into three major parts:

- The cap: the main body of the cap is a cylinder. I noticed that the bottom of the cylinder has a small sinking area in the middle. Therefore, I constructed another cylinder and have it cut into the bigger cylinder. I also have the fillets for the rims.

- The closing end: the part that closes up the tube

- The tube: I built a loft with the two surfaces between. I couldn’t figure out a way to smooth out the lines on the side.

What I really enjoyed during the process is that Fusion360 allowed me to add details to the model so it doesn’t have so many edges. A problem I faced is I’m not sure how to construct the inner structure of the cap and I think there might be semi-finished parts in the part-shop.

Looking into the future, I think Fusion360 is able to help us achieve a lot of amazing things through 3D printing. Because one advantage of using Fusion360 is it allows designers to build components and then assemble them together. It helps the designers to solve one of the most important constraints when using 3D printers, which is sizing. If we are able to break down a design into small pieces, we are able to make much bigger things. Also, since the defection rate of 3D printing is also relatively high (for me 2 out of 3 so far), It is also much easier to reprint a small piece if there’s any defection. I’m looking forward to future application of Fusion360 in my 3D printing project.