We designed a smart light switch that allows you to control the light with your cell phone and can be installed hassle-free. Want to know how we came to this idea and realized it? Please keep reading and find our demo in this post!

- Ideation

In the brainstorming process, we came to a consensus that we all want smart home appliances, such as remote light control, in where we live. However, as renters, we can’t install most of the devices because they require major modifications to the room plus they are expensive. It came to us that although smart home is becoming trendy these days, it is still very costly. Thus, we decided to work on the statement of “How can we make smart home cheaper?”

We further broke down our statement into three design objectives. First, the installation process should be hassle-free. Second, the device can be controlled in distance and no extensive technological knowledge should be required. Third, it should be universally applicable. Bearing those objectives in mind, we decided to make a device to control light. The device can be adhered to the wall on top of the switch and control the switch through mechanical movement. Besides, the device will need to be connected to our smartphones through Bluetooth or Wifi.

- Market Analysis

Based on our idea, we identified three target customer groups. The first group is short-term home owners, such as college students and young working adults. They won’t own the same room/house for many years, and most likely be unable to make major modifications to the house. Our device will also benefit the large home owners who don’t want to reengineer their house for installation. The third group will be the the elderly and disabled people. The smart light switch can make their lives easier without breaking the budget. Those who are disabled would have the ability to control the light switch without getting up from their seat. In addition to the accessibility, it would also just make it very convenient for pretty much anyone.

- Initial Design

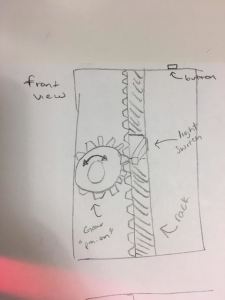

In our initial design, we planned to make a box that could be adhered to the wall with mechanical structures inside to move the switch up and down. We figured out two possible arrangements of the mechanics. The first is to use a combination of rack and pinion (Figure (a)). The rack will have a hole in the middle to fit the switch in. Another design is to have a motor pushes two rods in order to move the switch. The rods are also connected to a lever outside so the switch can still be controlled by the lever. We quickly realized as a team that this would be harder to actually make than we expected.

(a) (b)

(a) (b)

Figure (a) illustrates the initial rack and pinion design.

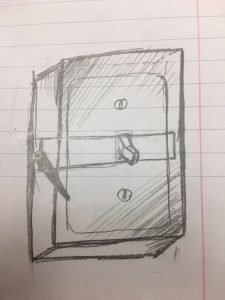

Figure (b) is a crude preliminary ideation sketch with a lever on its side.

- Iterations

We decided to go with the first design initially. The graph below shows the process of 3D printing an enlarged model of rack and pinion.

Although the model came out well, when we tried to print the gear in the actual size that we were going to use in our design, we realized that the 3D printer is not able to reach the level of precision we need.

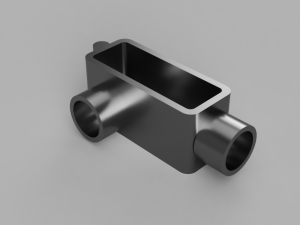

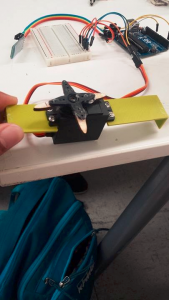

Alternatively, we found out that we could adhere the blade, instead of the pinion, to the motor and pushes the switch directly. The picture below is the motor with the blade. We extended the blade so it adds more contact surface area, making it easier to actually flip the light switch up and down.

- Final Project Delivery

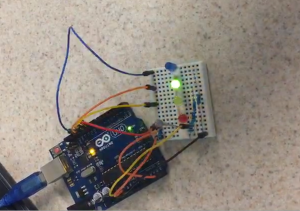

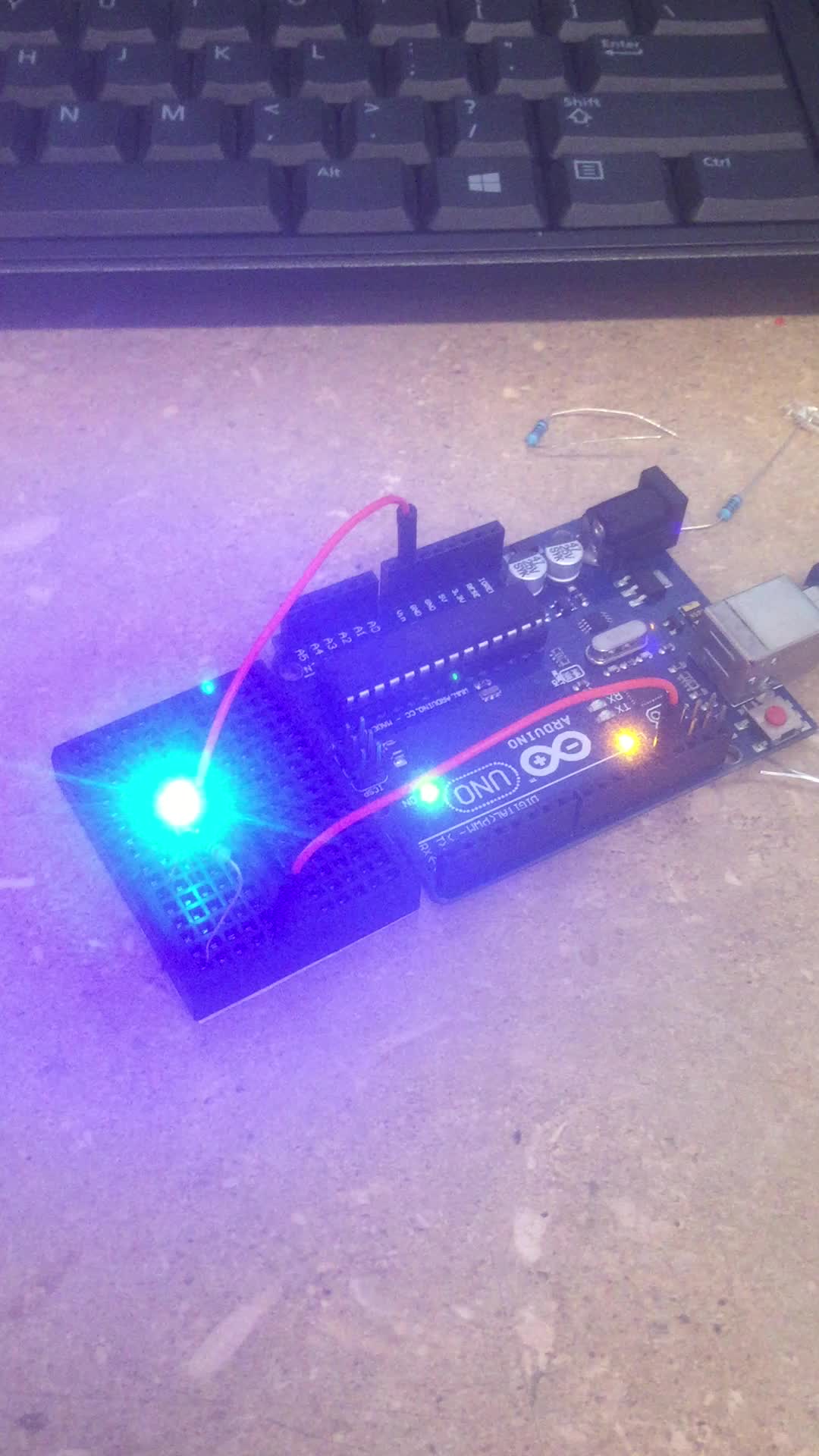

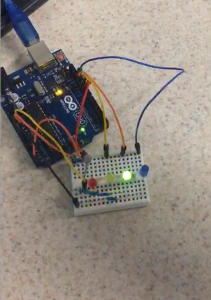

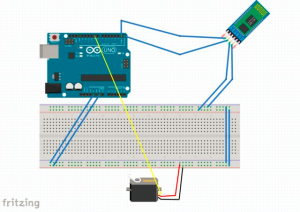

As our final design concept was based on making smart homes cheaper, we had to integrate a system which could control the Motor remotely. By integrating and Arduino Uno and HC -05 Bluetooth module we programmed the motor to turn to our specifications and also control it remotely.

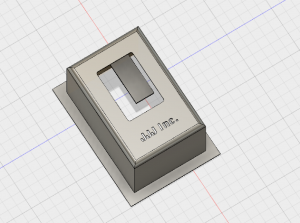

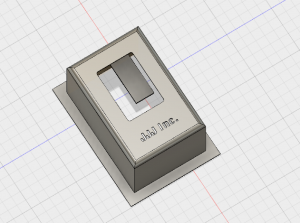

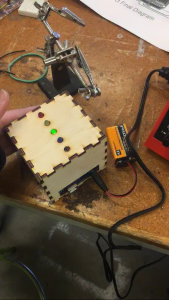

On the picture on the top you can see a Sketch of the Circuit wiring which includes the Motor, the module and the arduino. This sketch was done using Fritzing. The second image is of our final design housing of the light switch. This box was laser cut in the CU Fab lab with our team name embedded in the front! This box was designed in a way so that it mounts directly on top of the light switch and at the same time contains all the wiring inside of it.

In the top most GIF, we successfully were able to wire the Bluetooth module to control the movement of the motor blades!

These two GIFs illustrate our prototype at work; switching the light switch on and off with ease.

- Feedback and Future Work

Some of the feedback we received from friends and some students who used our prototype was geared towards a prototype which could allow the user to not only control the switch remotely but also have an option to manually turn it off and on. Some other suggestions were to make the housing a little bit smaller and easily portable to fit any toggle switch. After thorough research about the types of switches in and around homes, university buildings we found that the toggle (up and down) switch was the most common followed by the rocker as shown in the figures below. Hence, our future work aims towards redesigning the motor blades to increase our usability across all formats. For the research we have done, we have concluded that creating a motor blade to accommodate for the rocker switch would not be incredibly difficult to make, given our current setup.

Figure : Rocker switch (left) and the toggle switch (right)

Some of the other future iterations is to use small circuitry by using a custom microprocessor and a watch battery instead of a large 6V battery. This will help us reduce the size of our housing and make our prototype even more user friendly.

Our presentation slides are available here.