This has been one of the best classes I’ve decided to take throughout all four years of my college career. It fulfilled my expectations and provided me with even more, and I’ve already recommended this course to my underclassmen classmates. When I first heard about this class, I thought it was solely about how to create 3D printing designs and operate the 3D printers. Boy did I underestimate the things I’d learn! In this next section of this post, I will provide a list of the main things I’ve learned throughout the semester.

THINGS I’VE LEARNED:

3D Printing

During the first few sessions of BADM 395, we learned how to use a 3D printing slicing software called Cura and the Ultimaker machine to print out 3D products. We were also exposed to many open communities and sources like Thingiverse to gather creative ideas. Here’s a link to my first blog post.

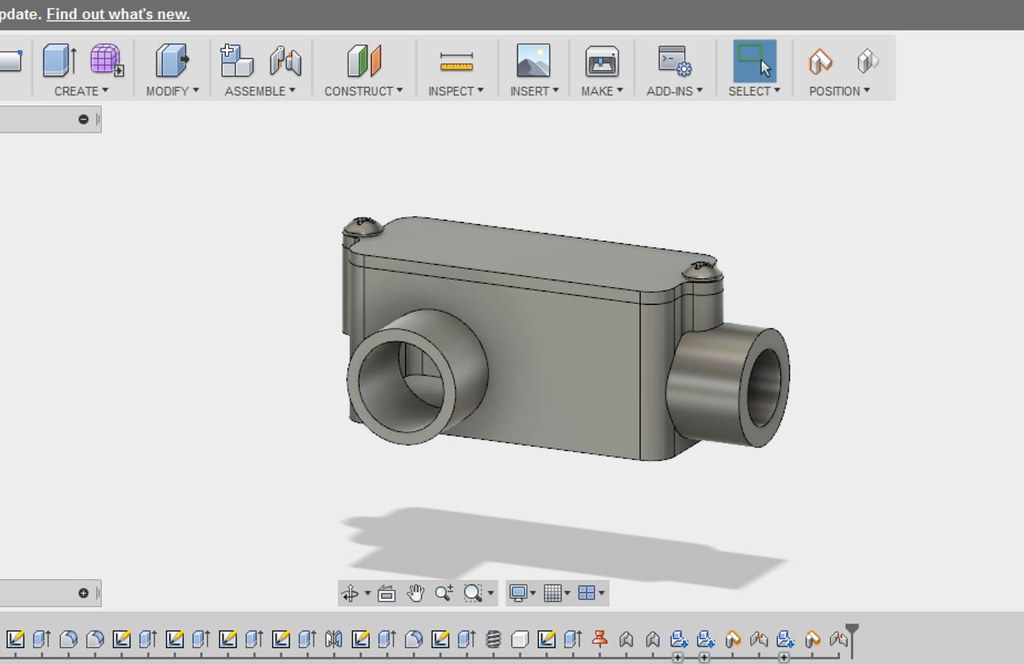

Autodesk Fusion 360

Learning how to use this 3D printing designing program was both challenging and fascinating. There were just so many functions available to make the perfect design that it definitely felt very overwhelming in the beginning. However, after following video instructions and watching guest speaker, Jeff Smith, demonstrate how to use Fusion 360, it became an amazing tool. Here’s my post about my first experience with this great program.

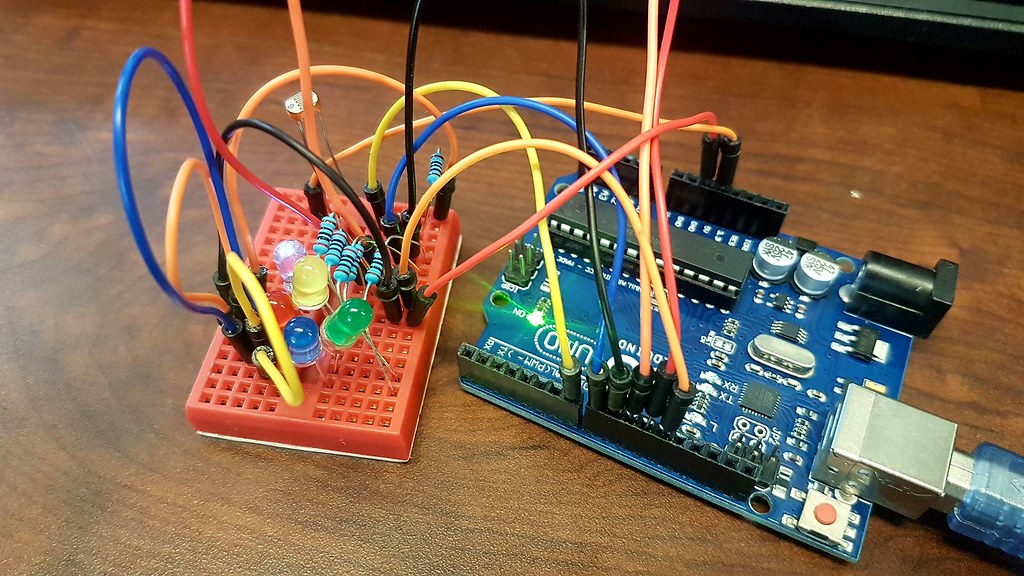

Arduino

Later in the semester, we had the opportunity to learn about the Arduino, soldering, and laser cutting at the CU Fab Lab. The Arduino is a programmable microcontroller which contains pieces of codes that execute on demand. The Arduino is then connected to LEDs, motors, and motion sensors via IO pins. We first learned how to wire the board. Then, we moved on to connecting it to a computer software and inputting codes that control the Arduino. Read more about it here.

Soldering

Also at the Fab Lab, I was exposed to soldering for the first time. It required steady hands and a lot of patience but was very well worth it in the end. I was able to solder wires together and connect them to the board and LED lights. Here’s more.

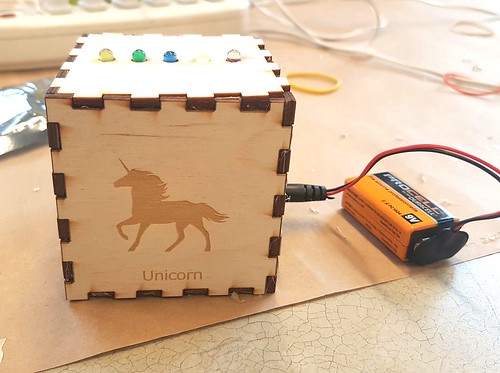

Laser Cutting with Inkscape

The last thing I learned at the Fab Lab was using Inkscape to create laser cutting designs. I learned the difference between cutting and rastering and how to safely operate the laser cutting machine. I had a lot of fun putting everything I’ve learned in the Fab Lab together and creating the final product shown in the picture below. Read more here.

FINAL TAKEAWAYS:

I cannot express how impressed I am in this Digital Making seminar and really encourage anyone, no matter your major or year, to take this course. For me personally, I’ve never thought of myself to have much to do with the area of art/design/technology, though ironically I’m a daughter of an artist. This class, however, changed my point of view on the maker world. It taught me that ANYBODY can be a maker, as long as you have a curious mind and willingness to learn and solve problems. In the future, I’ll definitely be more aware about the maker world and maybe utilize some of the things I’ve learned described above in my future career.