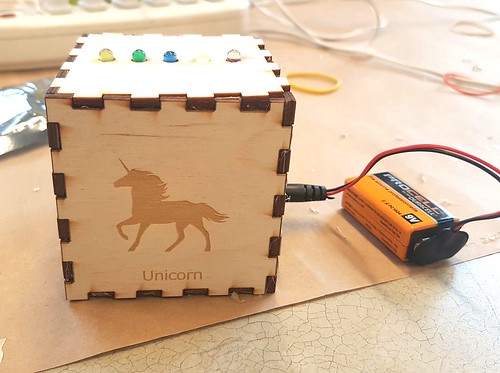

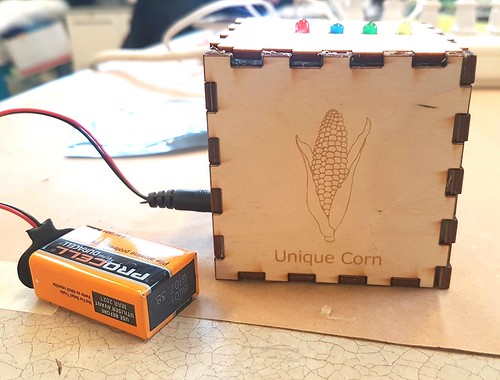

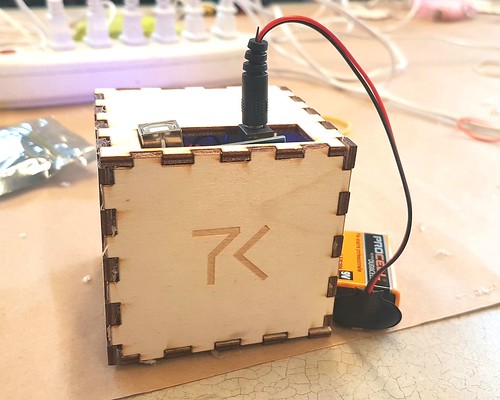

This week wraps up the third and final session at Fab Lab. It gave us a sense of achievement as we were able to put together everything we’ve learned in the past 3 weeks into our final product–a personalized LED lightbox.

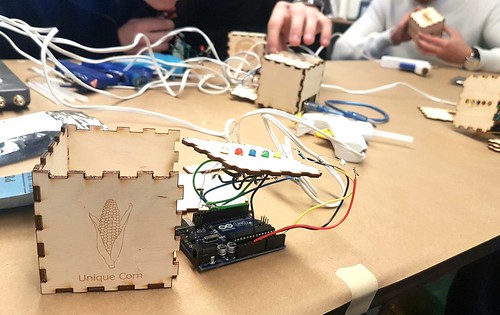

In this session, my group experimented with laser cutting. It’s a manufacturing technique that utilizes a laser which creates a beam of light to cut or raster on a panel of material. Common material used includes wood, acrylic plastic, and paper. For this project, we used Russian birch plywood.

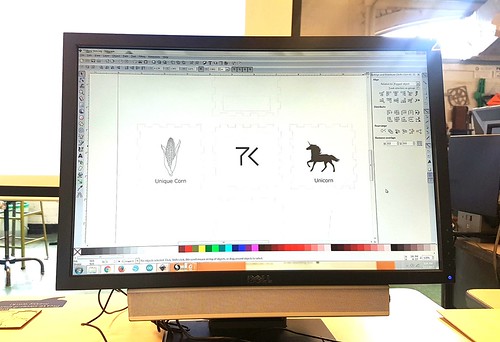

To create our design for laser cutting, we used a program called Inkscape. It’s a free and open source vector graphics editor that’s similar to Adobe Illustrator. It was pretty simple and straightforward to use and we learned how to convert a bitmap image downloaded from the Internet into a vector image, so that no matter how you scale it, the edges will be just as sharp and not pixilated. In order for the lines to be cut later on with the laser, it has to have a thickness of 0.001”. As for raster engraving, the darker the shade of the image, the deeper the raster. After designing our images, we saved the file as PDF and brought it to the laser machine to start the cutting process.

Staring at the laser machine while it did its work was actually entertaining, as shown in the video. We had to keep an eye on it the whole time to ensure it doesn’t catch on fire (which they said usually doesn’t happen, but who knows).

It took about 10 minutes for the machine to cut the 6 pieces as well as rastering 3 sides of the box. Fortunately, mine came out quite well though I had to use sandpaper to smooth out some of the edges. The next step was the exciting part–putting everything together. It took a lot of time and patience to assemble all the parts of the Arduino, LED lights, and wooden box with a hot glue gun, but in the end it was well worth it.

Oh so magical.

The major takeaways I’ve gotten after these 3 wonderful sessions at the Fab Lab:

- Technology is great and so much more than what we normally see. It’s not just about endless coding like what we usually imagine CS majors and software engineers do all day. The Fab Lab has taught me that it’s about combining different skills (coding, designing, soldering, fabricating, etc.) and sparking your inner creativity to make a variety of things, both for personal use and for the benefit of the society.

- Patience is a virtue. Yes, it’s triple cheesy but it’s true. I’m not kidding about the number of times I had to tell myself not to get too frustrated, whether it was soldering wires, assembling the LED, or gluing the final product together. This also applies to anything you want to achieve in life.

- Collaboration is key. You won’t go far trying to do something by yourself. Every person you meet knows something you don’t, so by sharing ideas with others you are able to accumulate a lot more knowledge which will help guide you in your creations.

Just to finish it up, I’m going to share a cool project that was done through Fab Lab: a 3D printed boombox. The board is written with Arduino language and can play music using an SD card and a 9V battery. I’m sure this bad boy will serve you well at a house party. 🙂

Hello Tiffany,

Great post, I love the visuals you provided. The unicorn laser engraving on your box is my favorite. I found your takeaways incredibly useful and will take them into consideration as I move forward with the final project. The boombox just goes to show all the amazing things that can come out of the Fab Lab. People should definitely utilize it more.