As part of the NSF-funded project NEESR: Reserve Capacity in New and Existing Low-Ductility Braced Frames (CMMI 1207976), full-scale testing of two concentrically-braced frames was recently conducted by Prof. Larry Fahnestock (PI), Prof. Eric Hines (Co-PI, Tufts), Prof. Robert Tremblay (Co-PI, Polytechnique), Josh Sizemore (PhD student, Illinois), Cam Bradley (MS student Tufts) and Thierry Beland (PhD student, Polytechnique) in the NEES@Lehigh facility. The research program is also supported by AISC, and steel for the test specimens was donated by AISC. These tests provide valuable new data on braced frame inelastic behavior, particularly mechanisms that develop after a primary limit state such as brace buckling or weld fracture.

In July, a one-bay two-story chevron configuration R=3 CBF was tested. It initially developed brace buckling in the second story, and subsequently a weld fracture at the brace-to-gusset plate interface was induced in the first story. Brace re-engagement, with strength similar to the pre-fracture condition, and a ductile long-link EBF mechanism, with beam flexural hinging, characterized the remainder of the test.

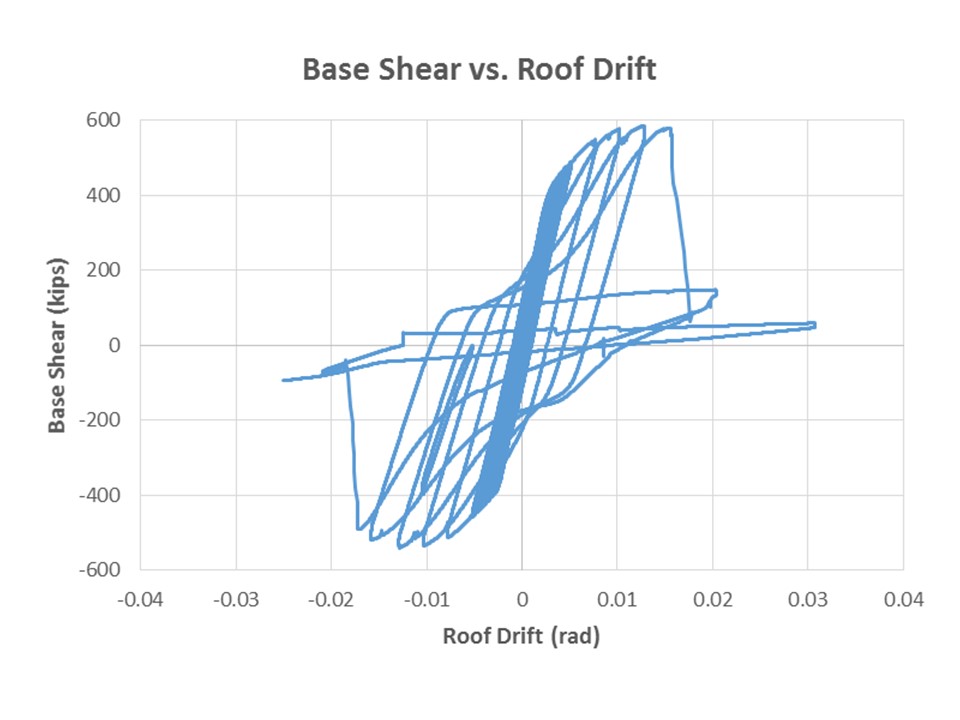

In September, a one-bay two-story split-X configuration OCBF was tested. It exhibited stable cyclic response, with brace buckling and yielding, up to 1.5% roof drift when a second story brace-to-gusset plate weld fractured at nearly three times the design base shear. Subsequently, the brace re-engaged in compression and the prior peak base shear in the opposite direction was nearly reached at -1.5% roof drift. In the next cycle, heading towards -2.0% roof drift, the first story beam-to-gusset plate weld fractured and concluded the primary portion of testing.