Week 6: My First Invention

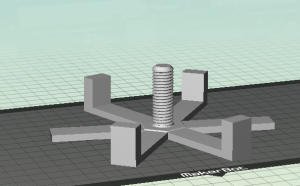

This past week, we had the opportunity to use Fusion 360 software to print our first creation. We had spent the past week playing around with different tutorials and exploring the different aspects of the software. After messing around for a few hours, many of us were able to produce metal bolts, headphones, and other practical devices. During class, I took the principle of building upon what already exists and decided it may be most feasible for me to build off the metal built I had made in my tutorial. I spent about 30 minutes thinking about all the different modifications I could make for the object and then as I played around, I remembered a design I had seen on Thingiverse. I thought about extending the different walls on the bolt to create a makeshift grocery bag carrier!

Making the Thing

Going through the different aspects of the software, I was thinking about the different ways I could make this product. I finally decided to use the ‘modify’ tool to expand the walls of each side of the bolt to become beams of greater length. By making these beams, I figured they could support the weight of grocery bags hung onto them. However, as I began making the various aspects of the grocery bag carrier, I found that I also needed something additional as a ‘hook’ like aspect. One of the assistants in our 3D lab provided me with some great insight (collaboration is ALWAYS welcome) and I ended up adding some protruding ends to the beams. With some consideration of the actual strength of the object and a little recollection of physics-force diagrams from high school, I came up with this thing!

What Will I Make Now?

I feel MUCH more comfortable with the Fusion 360 software now and I feel much more capable of creating an object from scratch. I’m still learning about the different nuances of the software, but I feel confident in my ability to create a relatively simple object and modify it to meet certain specifications. I have thought of some interesting product ideas, but I think the greatest challenge will be scaling the object in this software to ensure that what I think of in my head actually fits the needs I see in reality. Knowing how dimensions in a software translate into dimensions in real-life and then taking into consideration the potential error of the actual 3D printer itself is a very iterative and integrated process. I’m learning now that product development using additive manufacturing processes may require patience and dealing with frustration at times, but I’m excited to see all of the different ideas I may come up with!