As soft robots are the new normal, polydimethylsiloxane, or PDMS, is becoming ubiquitious in labs. You know it as the material that makes “sticky hands” you throw against the wall, and it can be a clear, or slightly cloudy (turbid) soft solid. It can be molded into any shape conceivable, especially shapes with more than one function. In this 2015 paper from ACS AMI, a molded device has a continuous system of bladders which make it walk, but also grippy feet for traction (see the video below).

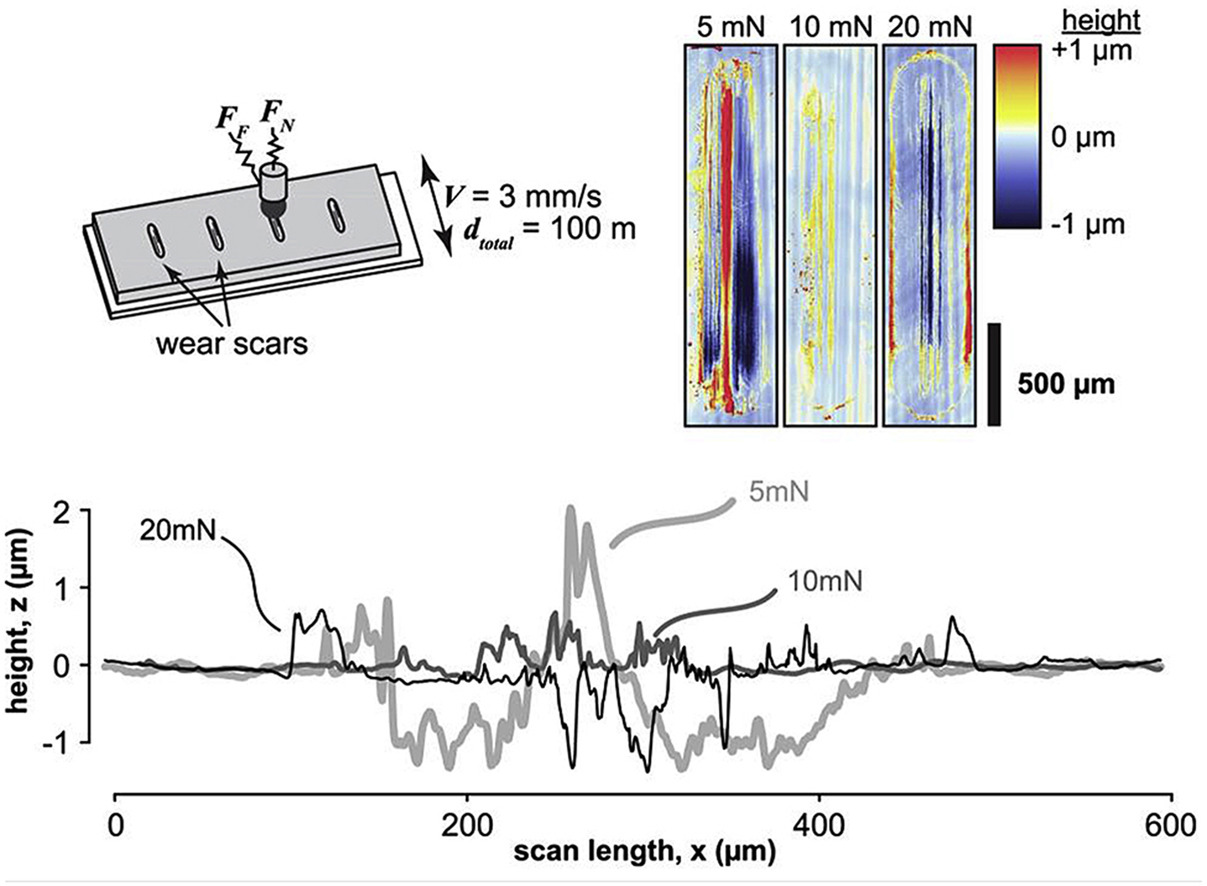

But how long can they walk? What kind of loads can you expect to grip with, and for how long, if there is friction? Our new paper in Wear, “Wear mode control of polydimethylsiloxane (PDMS) by load and composition,” Chris performed systematic wear of PDMS against a smooth probe, and carefully analyzed the resulting wear tracks to discover how the PDMS wears. Here are the hot tips! Don’t apply too light a load; you’ll get abrasive run-in. Don’t push harder than about 10% of the modulus; you’ll fatigue the contact. And don’t drop the binder concentration too much; you’ll sacrifice the surface for the traction you gain. Congratulations to Chris for his first accepted paper!