Ran Jin & Jiaqian Claire Chen

Idea Inspiration

Jin Ran and I get our inspiration from a Youtube video in which Mike Francesa spilled soda all over the desktop during his radio talk show. As a naughty girl growing up, there were countless times I spilled my drink all over the place. I personally found it very easy to spill your drink when you are concentrating on other things, like when you are typing a report on your laptop. So we came up with this idea of adjustable can/cup/bottle holder that can fit container that of any size and that can even charge a cellphone. The designed main function is to hold the container stable on the desktop.

Initial Design

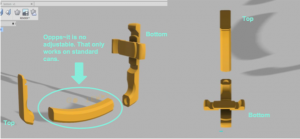

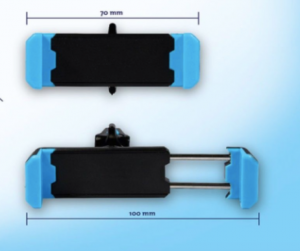

After exploring more about charging function and adjustable structures and considering our time budget, we decided to lower our expectation to design and print an adjustable cup holder that can fit most common-sized cans. We looked several existing products online (as shown below) and accessed their doability. For the first existing product, we were worried that if 3D printing out the sliding arms, the friction at the touching parts would be too big to allow the arms to slide out smoothly. For the second existing product, even though it’s a very good bottom part that can fit a lot of different-sized can, we need a vertical supporting structure that can change corresponds to the bottom, and we didn’t come up with a doable idea and we decided to look for more designs.

Design Process (C&R)

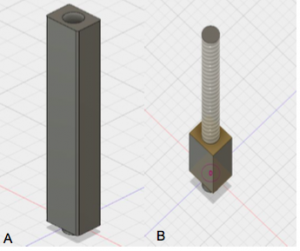

To create our own design, the initial step we did was collecting a variety of cup/can holder models from thingsverse.com. After analyzing the pros and cons of those projects, Clarie and I start to sketch the design on the paper. Later on, we transfer the final drawing to Fusion 360. The first prototype only works for standard size can because we ignore the large size drinks, such as Monster Energy or Arizona. Hence, we redesign the vertical holder part to be more adjustable so that it can fit any height of cans. Thanks to the suggestions from our classmate, we solve this problem with a spiral structure design. Part A applies for general size of cans, and depended on needs, Part B as a complement to adjust the height of Part A.

Difficulties and Challenges

The most challenging work of completing this project is utilizing Autodesk Fusion 360 to design the model. We are the beginners to learn this brand new software, although the course offered two relevant workshops to help us get familiar with the interface. Particularly, in the beginning, we spend lots of time and efforts on creating and modifying models. Thanks to the collaboration feature of Fusion 360, we are able to work individually on each small part and combine the designs together. However, the shortcoming of this feature is mismatching the sizes or measurements when we work separately. Another difficulty that we confront is size differences between the design and printing versions. For example, the diameters of the joint part are 10 mm on Fusion 360, but the printed sizes are changed somehow because these part are either larger or smaller to fit together. Last but not least, during the 3D printing, we find that there are several failures happening; particularly, the shape of the vertical holder is messed up due to the need of support.

Alternative Design

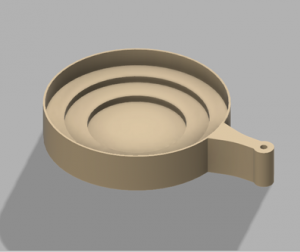

After printing out all the component parts, Jin Ran and I explored more in the Fusion 360 software. We found Fusion is a very efficient tool to design simple but useful everyday designs. For instance, if you want to design a cup holder, you can easily create one that is good for three different sizes by just using the cylinder and extrude function. (See below) We human once to live in a way that whenever we need any tools we make them, now I think it’s a great time to inherent this spirit given the presence of 3D printing technology.

Summary

The goal of our project design is to build an adjustable can/cup holder which will give the users the best drinking experience. The design should be comfortable and user-friendly for daily usage. The project also tries to prevent the issue of freezing hands when people hold cold drinks. In addition, the temperature sensor works as a reminder to help the users be healthy. The major reason why adding the monitor on the can holder is that cold drinks decrease human immune system function according to health researches/studies. Furthermore, long term taking cold drinks shrinks blood vessels and impacts digestion system. Therefore, with the temperature sensor add-on design, users could easily find out the optimal time to drink the beverages. Additionally, our design is strong and stable enough to protect personal property safety caused by spilling.

Takeaways

This project not only gives us a good learning opportunity to get hand-on experience on product design and 3D printing, but also inspired to use technology in solving small problems in our daily life. Although the current model we have is not perfect because several improvements can be done in the future, we still believe that the can holder is a meaningful product which makes drinking easier and safer. Design For America-UIUC workshop encourages us to brainstorm the idea, and Fablab workshops motivate us to make it practical for daily usage. In addition, we realize the importance of using a simple and creative design to solve difficulties through this project. A simple design and a small correction of existing design can make a huge impact on individuals and communities.

Completing our prototype, we try to self-questioning and think about future improvements to make the can-holder and even 3D printing become better and efficient. First and foremost, during the printing process, the printers do not function very well since the the object fails two times. Fortunately, we break down the design into couple of parts which allows us to print separately. However, unnecessary material and time waste still happen in this case because if the project fails in the progress, we have to restart it in the beginning. The possible solutions on this issue include perfecting design in advance or increasing the functions of 3D printing machines. In addition, one thing we should take care in the future is having a product design plan before starting the project The plan covers details on different stages, such as define, ideate, prototype, build and analyze. Without a successful plan, it will be difficult for each team member to follow the instructions and make right decisions. Lastly, focusing on the project itself, we would like to continue to work on the design by adding other useful features. For example, the product is able to collect the energy from drinks (hot/cold) and convert into electricity for cellphones, watches, any USB applied products. The holder is a sustainable design that transfer energy and also be able to collect water on cold drinks due to liquefaction. Another interesting function we are discussing is adding the bluetooth design that connects to phone or car. Similar to the popular sports bands, the can holder could provide personal drinking and health records.

![IMG_1641[1]](http://publish.illinois.edu/digitalmaking2016/files/2016/04/IMG_16411-300x225.jpg)