Research

In the Rogers lab for Soft Matter Research at the University of Illinois, we use a variety of experimental and computational tools to understand and model advanced colloidal, polymeric, and self-assembled materials for biomedical, energy, and environment applications. Much of the research is collaborative with investigators and institutions from around the world.

Our research is multidisciplinary, sitting at the interface of chemical engineering, materials science, and soft matter physics. Our primary field of study is rheology, the science of the flow and deformation of soft matter, where we seek to understand and control non-Newtonian fluids.

We use the new concepts developed from our experiments to inform and improve the latest theories. We have made advances in fundamental understandings of basic measurements as well as developing models specific to particular classes of materials.

STRUCTURE-PROPERTY-PROCESSING RELATIONS

In collaboration with the National Institute for Standards and Technology (NIST) Center for Neutron Research (NCNR) (Gaithersburg, MD), the Institut Laue-Langevin (Grenoble, France), and KU Leuven (Belgium), we combine scattering of light, x-rays, and neutrons with carefully controlled deformations to understand the microscopic causes of macroscopic responses. We use static, steady, and transient conditions to create dynamic understandings.

NOVEL EXPERIMENTATION

The development of a new rheological toolbox is required to probe the dynamics of modern smart materials. We are developing tools to understand rheologically nonlinear responses in ways that will allow us to tailor materials to the required processes, or alter the processes based on transient material behaviors. These tools allow us to probe metastable states of matter that only exist transiently under specific conditions, and to follow material responses with unprecedented resolution. We use the lessons learned from such studies to develop the latest generation of models.

We have developed novel analysis methods that are opening the doors to a wide array of new experimental protocols that more closely relate to conditions experienced by materials in their native environments.

COMPLEX FLUIDS

Yield stress fluids are materials that require the application of a minimum force, or stress, before they begin to flow. Think of toothpaste, cosmetics, foods like mayonnaise, muds, snow, and other soft solids that flow. A yield stress will give a material specific qualities that can be desirable or disastrous.

Thixotropic colloidal suspensions are characterized by their time-dependent microstructural changes under deformation. They are still poorly understood, despite their widespread use in food and cosmetic products, coatings, and the mining industry.

Polymeric suspensions have biological, energy and environmental, and industrial relevance. How they behave when taken out of equilibrium by strong and rapid flows can lead to dramatic changes in their physical properties, such as the dynamic color change shown below for a single bottlebrush block co-polymer system. These materials show great promise for 3D printing applications.

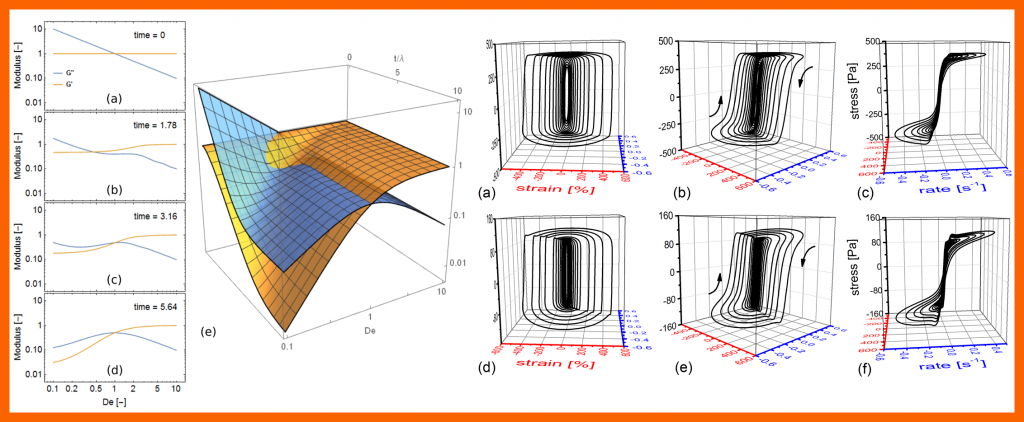

The Giesekus model for polymeric fluids is solved numerically for a large amplitude oscillatory shear deformation. The stress response is shown on the right as a function of the strain and the strain rate. Our newly-developed analysis allows us to track the evolution of the liquid-like (G”) and solid-like (G’) characteristics throughout the deformation shown on the left. To get your copy of the SPP freeware used to calculate these terms, contact Prof. Rogers.