This past semester has been a truly engaging and rewarding experience all due to the Digital Making course. I first enrolled in the class because I had an interest in 3D printing; little did I know that the class was so much more than that. Throughout the course we were able to work with 3D printing and scanning, Fusion 360, digital embroidery, and Arduinos. We also went on a few field trips to the Beckman Institute and the Fab Lab. Some of the students also took the opportunity to go to Deloitte in Chicago. It’s been such an exciting time being in this class and it’s opened my eyes to the maker world.

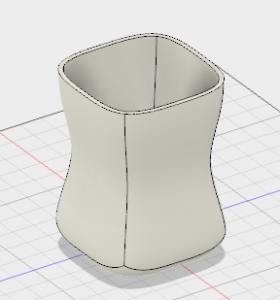

As mentioned, over the semester, we worked on a variety of projects including making a print of ourselves! The entire process was completely new to me. We used a portable scanner that took a rough scan of our heads and uploaded it where we could make any additions or changes to the model. I chose to personalize it with my name and soon we had our own 3D print! Diving deeper into the 3D printing and modeling realm, we started learning about Autodesk Fusion 360 which is a software that enables users to start from a 3D box and from there model anything imaginable. One of my classmates, Austin, designed an entire spaceship, very cool. Fusion 360 taught me that it takes time and lots of practice to get used to such advanced software, but if you put in the effort then it really does pay off.

Working with Fusion 360

Making headphones in Fusion 360

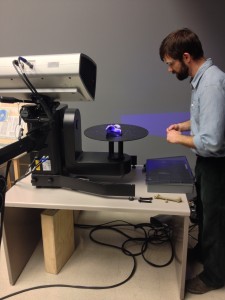

The trip to Beckman was interesting as well. While there we saw Travis work on scanning Arielle’s racing glove with the very high-tech and expensive scanner. I learned that there is a lot of editing and cleaning up that has to be done when scanning so it’s very tedious work. What was also interesting was that the scanner couldn’t pick up certain types of material or surfaces. In this case, talcum powder is best used to help the scanner pick up the object. I would have loved to spend more time watching Travis at work and possibly to some more proactive activities at Beckman.

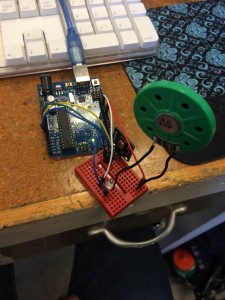

The Fab Lab, on the other hand, was very much so hands-on. Here the staff led us through all different types of making activities such as embroidery, Arduinos, and laser cutting. Everyone there is super friendly and always willing to lend a helping hand if need be. For the digital embroidery, I started out by choosing a design on Google and with some editing it was ready to be uploaded to the machine. My design took a while to color in all of the leaves, but it turned out great. The Arduinos are very small in size, but they can be applied to many different things. We were able to install a light, a sensor, and a speaker. While in the Arduino lab, some of us worked on soldering wire to speakers which was a lot of fun!

This class has given me a strong foundation to further strengthen my skills in the making community. I’d like to learn more about Arduinos and their application because there are so many possibilities out there. From taking this course, I’ve also looked at things differently, especially products. Recently, when I was at my parent’s house I noticed a specific product that was very clever life hack and could easily be 3D printed. We were very lucky to have such amazing opportunities and professionals that helped us through the semester to develop our skills as makers. As a graduating senior, Digital Making was one of the most fascinating, hands-on classes I’ve taken.