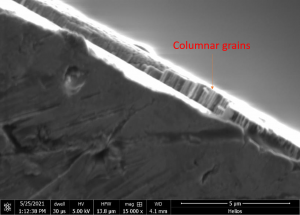

The University of Illinois will support the proposed work scope for 2020 CFA 20-19076 (University of Wisconsin, UW, prime) by performing Cr coating depositions on Zircaloy 4 tube specimens. The tube specimens will be provided by UW. The UIUC effort will involve attempts to optimize the Cr coating thickness deposition parameters (primarily sputter target power). In addition, characterization of the Cr coatings will be undertaken at UIUC. This will include X-ray diffraction analysis and SEM characterization in cross section to quantify coating thickness and grain microstructure. If permitted by the limited UIUC budget, autoclave pre-aging LWR simulated immersion will be performed. The UIUC team will then transfer the coated tube specimens to UW for further testing as specified by the UW portion of the work scope. The ultimate goal is to test AFT cladding in the TREAT facility at INL.

Cr coated Zircaloy tubing.

SEM image of columnar grains in Cr coating on Zircaloy.

The three sputter guns with Cr targets simultaneously running at 50 W in the dedicated magnetron sputtering facility in the H Lab.