The following facilities are available at ARL VTD to facilitate Research

High-Temperature Propulsion Materials Laboratory (APG)

High-Temperature Propulsion Materials Laboratory (HTPML) houses a hot particulate ingestion rig (HPIR) with 1650 °C max temperature, hot gas flow of 0.14 – 0.36 kg/s, impingement velocity of 120 – 610 m/s, sand/salt ingestion capability of 1 – 200 g/min injection rate with a dual feeder system. A button-cell flame rig for rapid testing of multiple material compositions under oxy-acetylene (3160 °C) and oxy-propane flames (2820 °C). Thermomechanical fatigue testing system with 1500 °C max sustaining temperature, capable of in- and out-of-phase thermomechanical cycling and creep testing. High-temperature air-jet erosion rig with maximum sustained temperature of 1065 °C, particulate speeds of 30 – 150 m/s, and particulate flow rates from 1 – 5 g/min. FLIR IR camera for thermal imaging up to 2000 °C (3632 °F). Single-wavelength and dual-wavelength pyrometers for temperature measurements from 260 – 3000 °C. Laser Doppler velocimetry (LDV) and particle imaging velocimetry (PIV) for measurements of particulate velocities and distributions within hot gas flows.

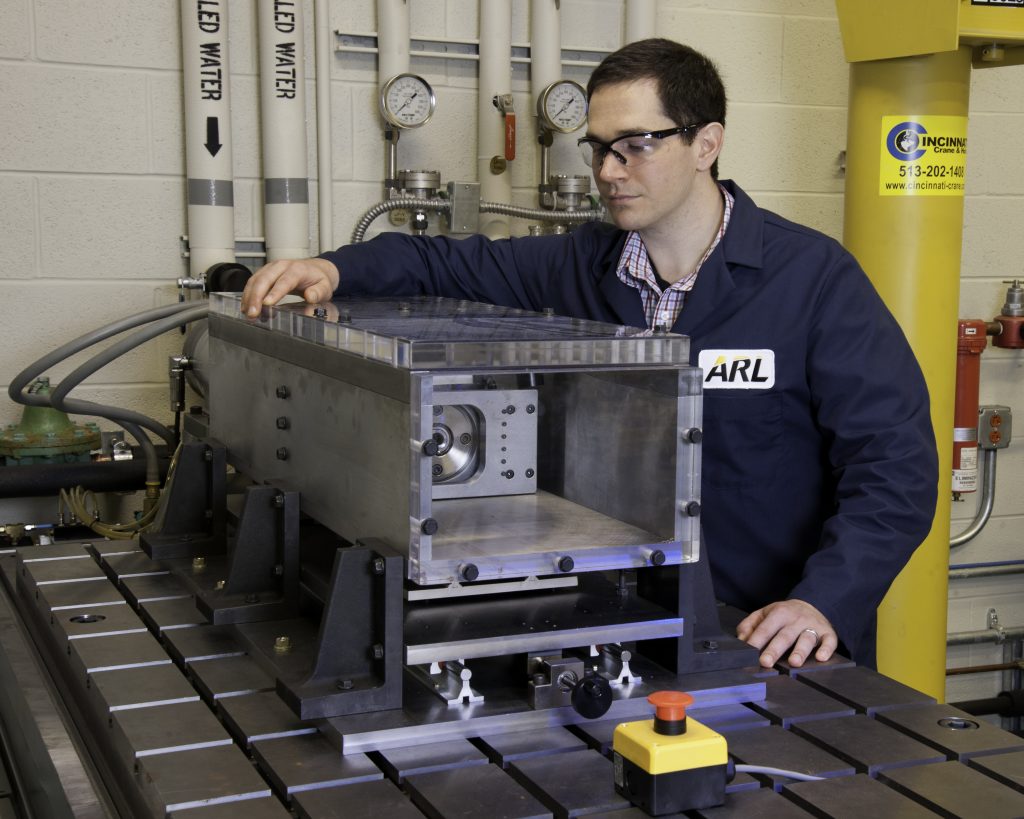

Powertrain Tribology and Components Laboratories (APG)

These labs are equipped to study fundamental friction, wear and lubrication phenomena as well as material response and durability, dynamics and diagnostic methods. Tribometers are available to simulate continuous rolling/sliding contacts as well as reciprocating contacts. The laboratories also contain purpose-built and versatile research rigs for study of bearings, gears and other mechanical components under normal and adverse conditions up to speeds of 60,000 rpm. A transmission research stand is also under construction for drivetrains up to 2000 hp. A hybrid electric experimentation laboratory includes a high response 150 kW dynamometer and programmable power supply. Instruments for the characterization of specimens available include: high-speed ball-on-disc tribometer, UMT modular tribometers, hardness tester, optical and confocal laser microscopy, Auger emission spectrometer, 25krpm and 60 krpm component stands, 22-kip servo-hydraulic mechanical testing machines, 5,000 rpm multi-station mechanical component stand, grease degradation bearing stand, gear and bearing diagnostics rigs, transmission test stand, vibration and acoustic emission instrumentation, laser vibrometer.

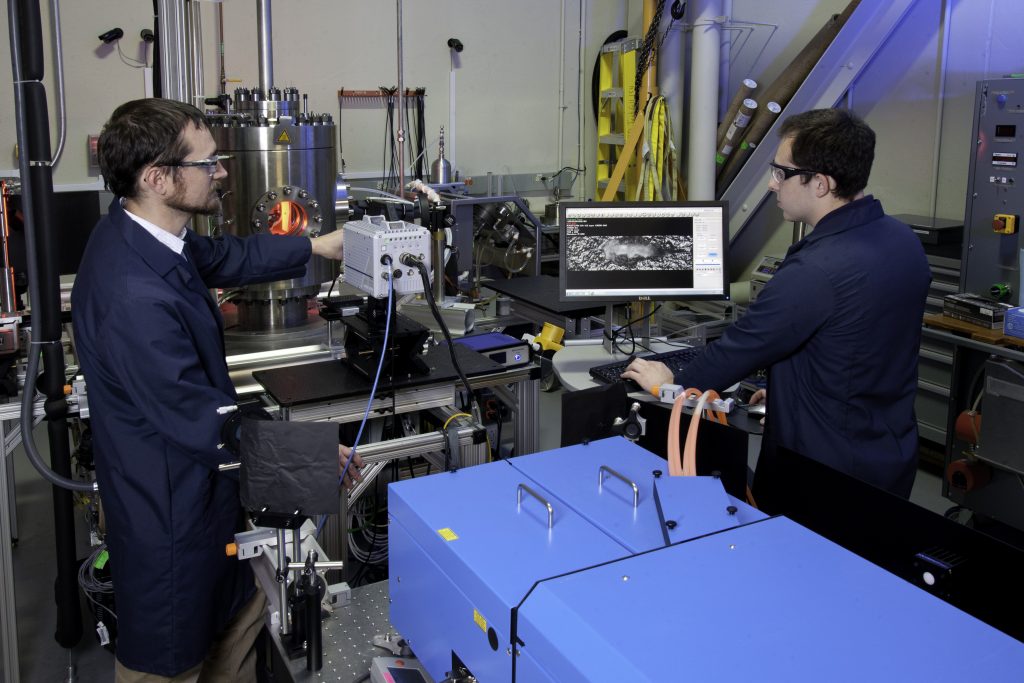

Spray Combustion Research Laboratory (APG)

ARL has an operating high-temperature pressure vessel (HTPV) system with various laser diagnostics to measure liquid spray and combustion processes. There are three different fuel benches: one common-rail fuel bench, one injector fuel bench that is hydraulically-actuated and electronically-controlled, and one air pump-driven fuel bench. Each bench delivers fuel to an injector at various fuel pressures (over 2000 bars with the air pump-driven fuel bench) with different injector types. The injector analyzer bench can characterize and map an injector, and various injector samples. The HTPV has the capability to operate up to 150 bar chamber pressure, 1000 K chamber temperature, and 0% to 21% oxygen concentrations in the test section. All three parameters can be independently controlled. This laboratory was established to (1) provide an understanding of injector performance under “realistic” operating conditions for range of injector parameters, (2) provide an understanding of the impact of fuel properties on the detailed spray and combustion processes, and (3) generate a database of spray and combustion measurements. These data are being used in 3D Computational Fluid Dynamics (CFD) codes to simulate real engine spray and combustion processes, including piston motion and in-cylinder turbulence.

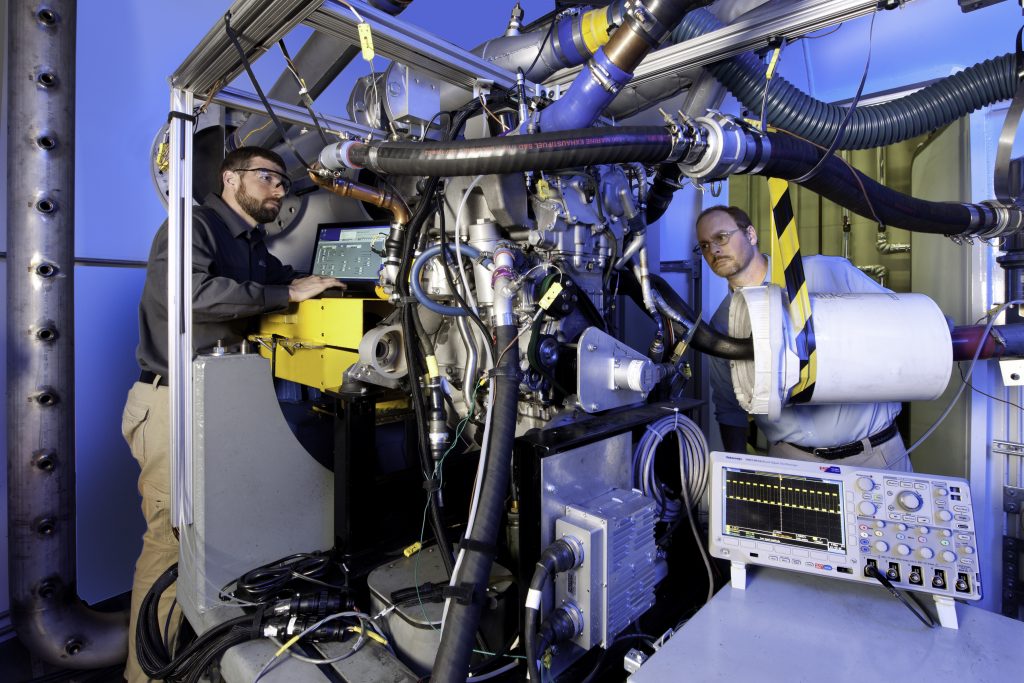

Small Engine Combustion Research Laboratory (APG)

The Small Engine Combustion Research Laboratory (SECRL) is equipped with a 302-hp dual-ended AC dynamometer and an inline torque meter on both ends. It has a Ricardo Hydra single-cylinder thermal/optically accessible engine on one end and various multi- or single-cylinder engines on the other end. The SERCL is equipped with the state-of-the-art equipment and instruments including a sophisticated data acquisition and control (DAC) system with numerous high-speed and low-speed channels, an Altech 7-gas analytical instrument, 2-ch AVL noise meter, AVL opacimeter, AVL blow-by meter, combustion air flowmeter, intake and exhaust pressure control valves, fuel conditioning and measurement system, closed-loop control charge air cooler, closed-loop control cooling column, ECM Lambda 5220 analyzers, B&K research-grade microphones.

Small Engine Altitude Research Facility (APG)

The Small Engine Altitude Research Facility (SmEARF) houses an altitude chamber capable of an altitude up to 30,000 ft, combustion air temperatures ranging from -40 to 130°F and an engine speed up to 30,000 rpm. A dedicated fuel chiller allows fuel temperature control as low as -60°F. SmEARF is equipped with the state-of-the-art equipment and instruments including a sophisticated data acquisition and control (DAC) system with numerous high-speed and low-speed channels, two AC dynamometers for power from 1 to 250 hp and inline torque meters, a gear box for extended engine speed, multiple air flowmeters including Laminar Flow Element, exhaust flow meter, fuel conditioning and measurement system, closed-loop control charge air cooler, closed-loop control cooling column, ECM Lambda 5220 analyzers, B&K research-grade microphones.

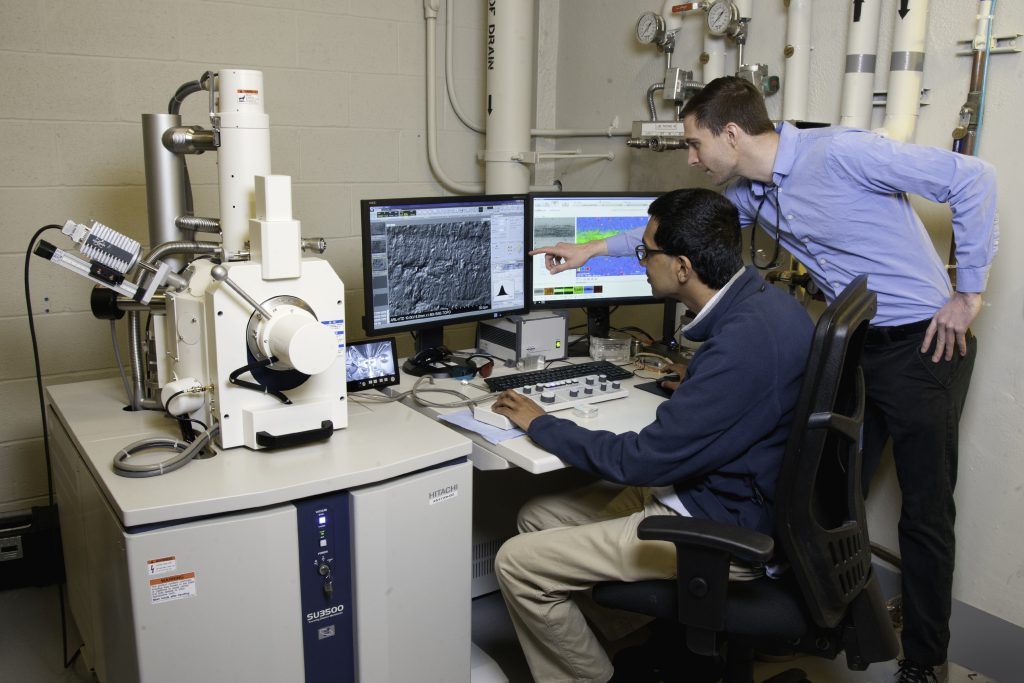

Propulsion Materials Characterization Laboratory (APG)

The Propulsion Materials Characterization Laboratory consists of the following: a Zeiss LSM 700 confocal laser scanning microscope to determine surface contours and roughness parameters; a PHI 660 scanning Auger electron microscope with sputtering capability for near-surface, high-resolution imaging and chemical analysis; a Sonoscan Gen6 scanning acoustic microscope for non-destructive evaluation of surface texture and sub-surface porosity; and the Hitachi SU-3500 scanning electron microscope for high-resolution imaging with a Bruker Quantax energy dispersive X-ray spectrometer for elemental analysis.

Bearing Laboratory

ML-Based Mechanical Component Diagnostics Laboratory