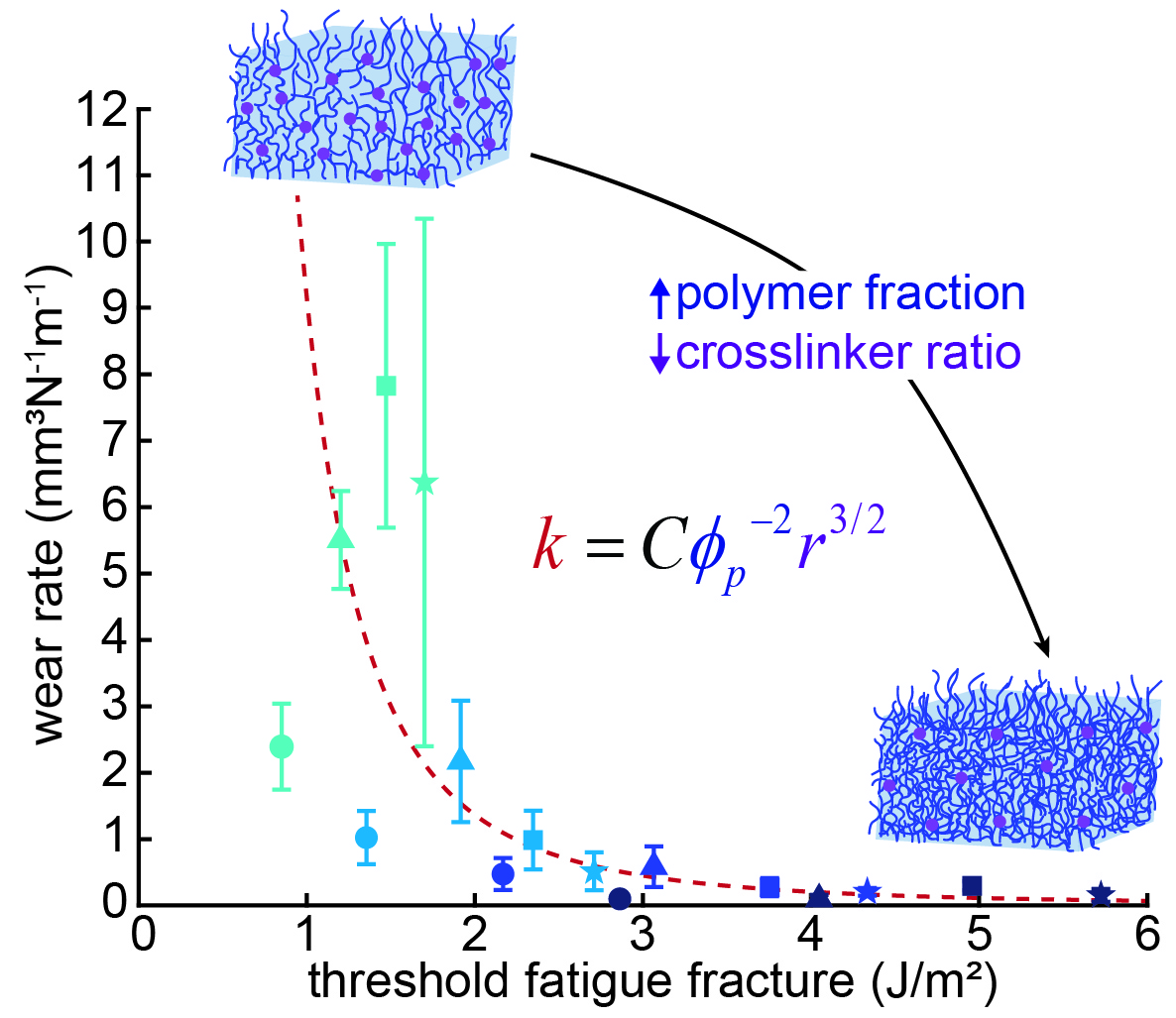

In this work Shab made and tested a variety of compositions, from viscoelastic to brittle, and analyzed how susceptible they were to wear. We measure at the volume of material removed from the surface due to gentle abrasive wear, and measure it using scans from an optical profiler.

The other tricky part is trying to connect that wear volume to a mechanism: did the wear break off like a brittle fracture? sweep away like a ductile event? In this case we started from the observations of brittle fracture, and calculated the minimum amount of energy it would theoretically take to break each type of polyacrylamide hydrogel (we used recent papers from the Suo group at Harvard as a basis). Then we compared that with the amount of wear observed. It turns out that these two things correlate quite well! So initially we can say that the mechanism of wear is likely microfractures of the surface. Read our paper here:

https://doi.org/10.1021/acsapm.0c00769