Shape memory alloy (SMA) is a class of “Smart Materials” that can exhibit unique thermomechanical phenomena (Shape memory effect and superelasticity/pseudo-elasticity), which involve the restoration (remembrance) of the SMA’s original shape after being excessively deformed. Shape memory effect (SME) is the thermally-triggered shape recovery of SMA when the alloy is in the martensite phase (low-temperature phase); however, superelasticity effect (SE), which is observed at the austenite phase (high-temperature phase) is the ability of the mechanically stressed alloy to restore its original shape when unloaded even after being strained beyond its linear range.

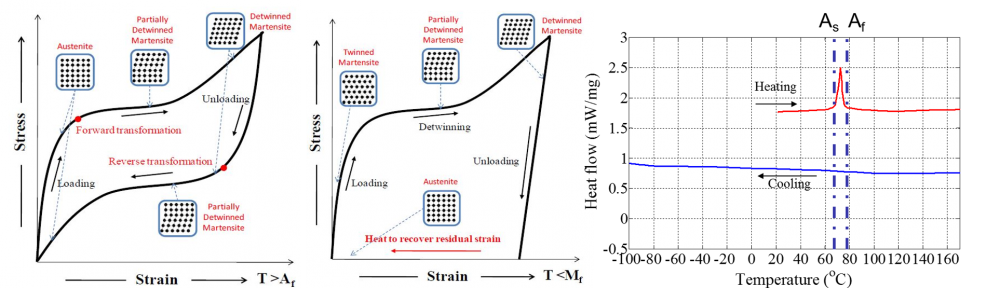

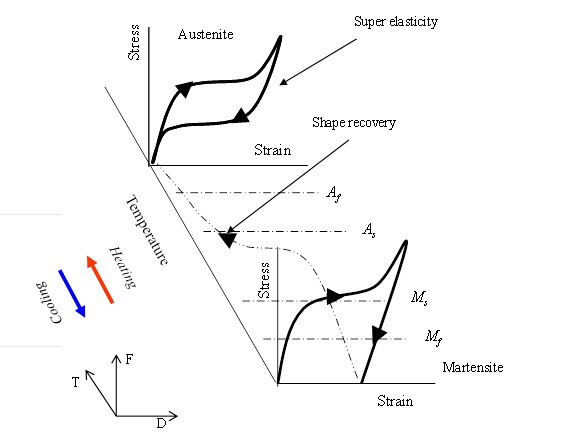

Figure 1. Stress-strain behavior of SMAs in the austenite and martensite phases

A typical SMA exists in either 100% martensite phase, 100% austenite phase, or in a mix between the two phases. A key factor that defines the alloy’s phase is temperature. Fig.1 shows the stress-strain behavior of a SMA in its austenite (top) and martensite (bottom) phases. The figure also shows four horizontal lines representing the four transformation temperatures which are unique characteristics of every alloy. As depicted in the figure, at temperatures above the austenite finish temperature (Af), the alloy is 100% austenite and thus behaves super-elastically (i.e. recover its pre-deformed shape upon unloading), while at temperatures below the martensite finish temperature (Mf), the alloy is 100% martensite and thus behaves inelastically (i.e. large residual strain is sustained upon unloading). Shape memory effect (SME) is a unique phenomenon where the martensitic alloy can recover its pre-deformed shape after being excessively strained, simply by heating the alloy to a temperature above Af. If restrained, heating the deformed martensitic alloy will result in the induction of a large recovery stress. In most binary alloys such as the well known NiTi, cooling the alloy to typical ambient temperatures will result in the loss of the recovery stress. This is mainly due to the relatively narrow thermal hysteresis, which is defined by the difference between the austenite start temperature (As) and the martensite start temperature (Ms) (see Fig. 1). Other ternary alloys such as the NiTiNb are characterized by a wide thermal hysteresis. Therefore, even when the temperature drops to typical low ambient temperatures, the alloy still maintains its recovery stress.

The SMS research group at UIUC is specialized in studying the potential application of the unique thermomechanical phenomena of SMAs in civil engineering applications.