The research carried out by the Shape Memory and Structures (SMS) research group at the University of Illinois aims at advancing the knowledge in the field of advanced and smart materials and their applications in all types of structures to mitigate the effects of natural and man-made hazards such as earthquakes, tsunamis, windstorms, blasts, etc.

The SMS group plays a unique role in bridging the gap between two major research fields, namely structural hazard mitigation and material science and engineering. Below is a sample of the research projects pursued by the SMS research group at UIUC:

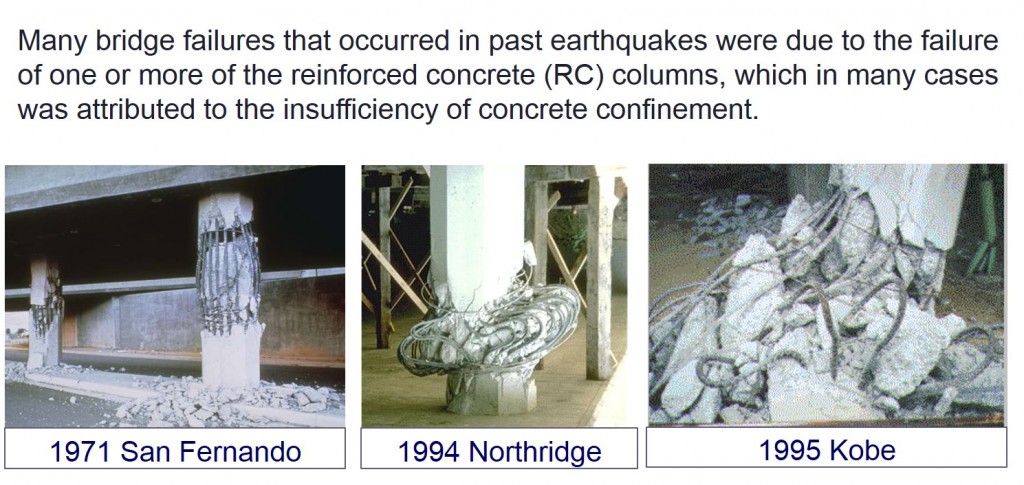

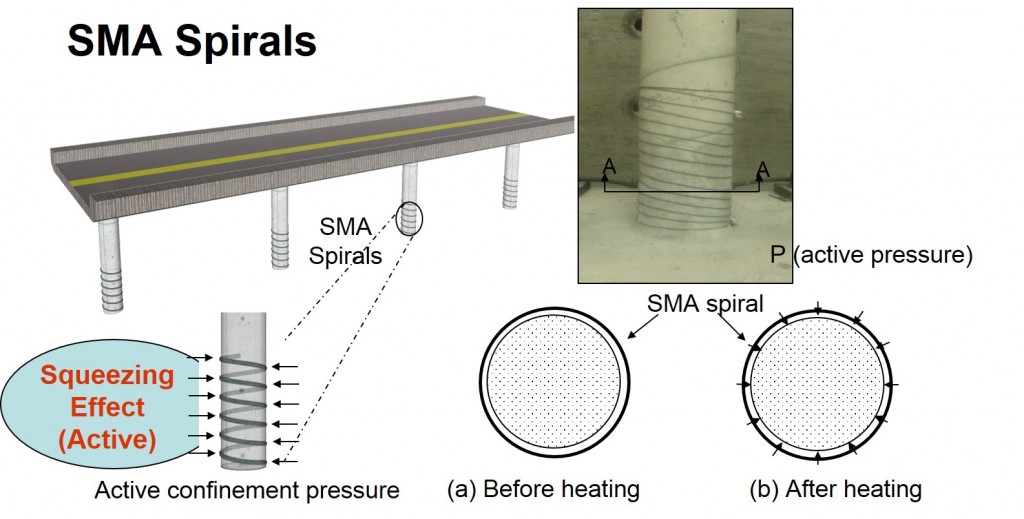

- Innovative Concrete Confinement Technology for Natural Hazard Damage Mitigation using Shape Memory Alloys

- Description:Concrete confinement has been proven to be effective in enhancing concrete strength and ductility, which are essential for structures prone to extreme loading events. There are mainly two types of lateral confinement, passive and active. Passive confinement, in which confinement develops as loading is applied, is commonly used in practice and applied in concrete structures as internal transverse steel reinforcement (e.g. spirals, hoops, stirrups), external steel jackets, or external fiber reinforced polymer (FRP) jackets. Active confinement, on the other hand, is applied prior to loading, which has been verified by previous researchers to be more effective in improving concrete strength and ductility than passive confinement. However, the application of active confinement using conventional materials (e.g. steel strands) has been unsuccessful and costly. In 2007-2008 SMS research group at UIUC proposed an innovative technique for applying active confinement in an easy and reliable manner using thermally prestressed Shape Memory Alloy (SMA) spirals.

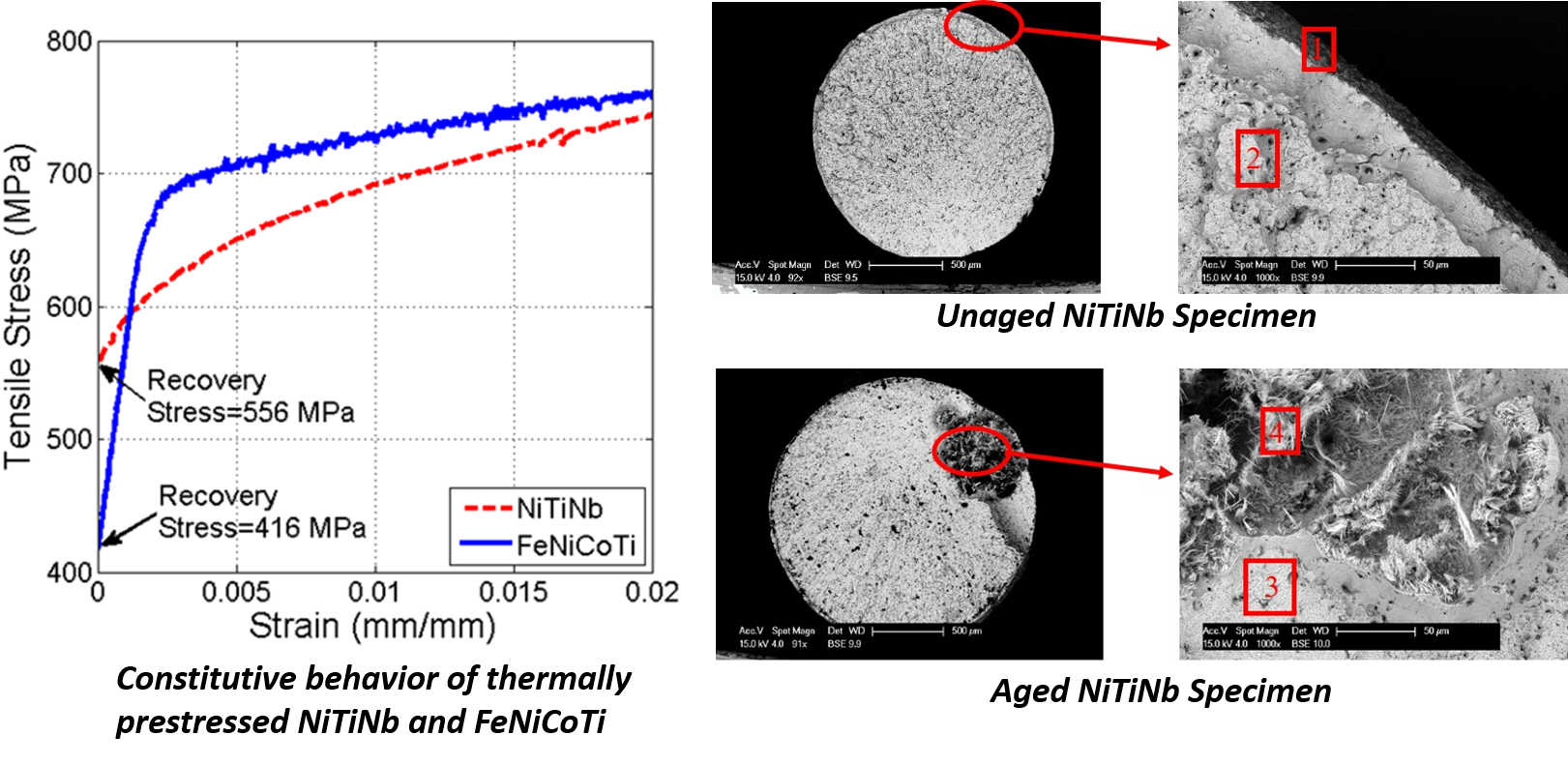

- Durability and Long-term Behavior of NiTiNb and FeNiCoTi Shape Memory Alloys Under Harsh Environmental Conditions

- Description: The research on the application of shape memory alloys (SMAs) in prestressing concrete structures has shown very promising results over the last few years, however, the long-term behavior of NiTiNb and Fe-based SMAs, such as corrosion resistance under harsh environmental exposure, is not fully understood. The main objective of this research is to investigate the influence from corrosive conditions on the mechanical behavior of these alloys by the means of accelerated aging test methods and exploring the effectiveness of using surface treatment to improve corrosion resistance.

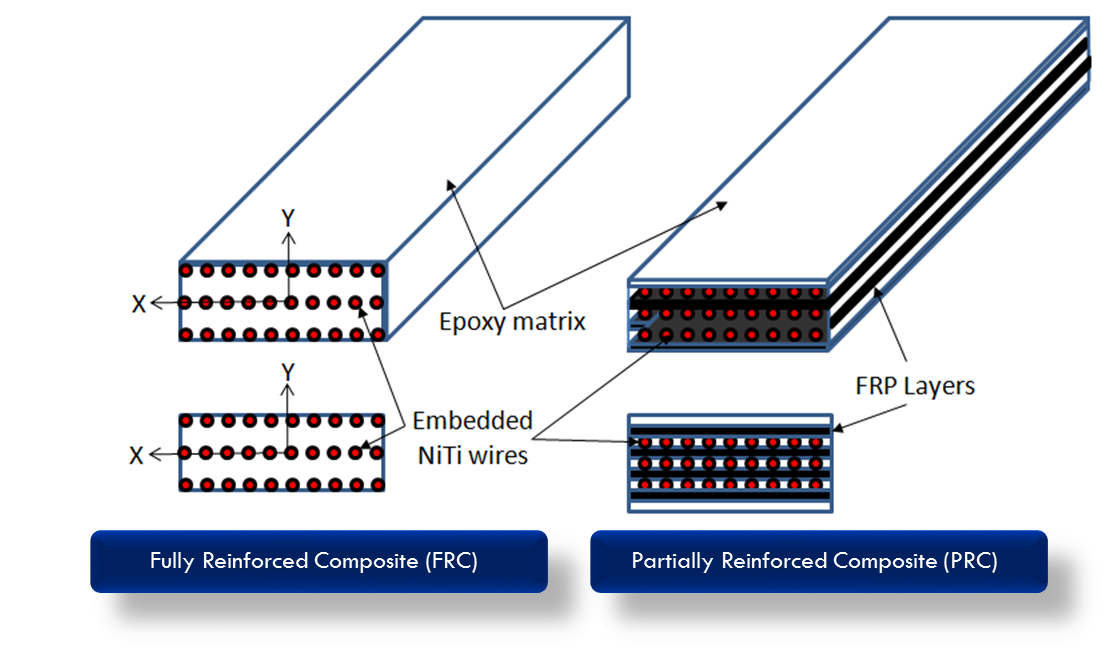

- SMA-FRP Composite Reinforcement for Enhanced Performance of Concrete Structures under Sequential Ground Motions

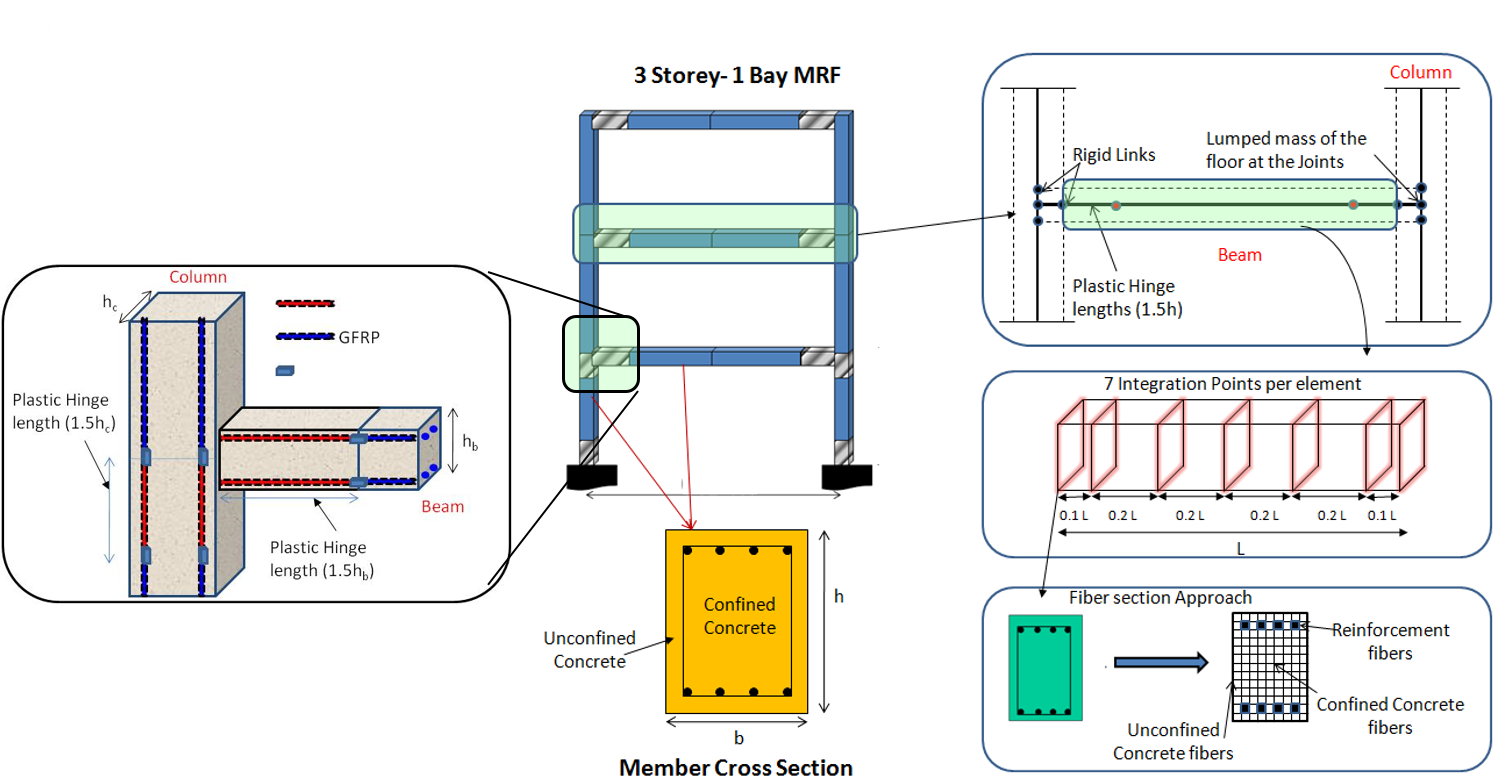

- Description: For many years, steel has been used as the primary reinforcing material for concrete structures. Despite requisite stiffness, strength, ductility and desired deflection properties, steel reinforcing bars have tendency to incur permanent plastic deformations under excessive loading. Recently, fiber reinforced polymer (FRP) reinforcing bars have also been used in concrete structures to address corrosion issues typically associated with conventional steel bars. However, due to their linear elastic behavior, they are not considered in structures which require ductility and damping characteristics. The use of shape memory alloys (SMAs) with their nonlinear-elastic behavior in the composite could potentially provide solution for this problem. Small diameter super-elastic SMA wires, coupled with polymer matrix is sought in this research as reinforcing bars in reinforced concrete (RC) moment resisting frames (MRFs) to improve the performance of the frames in terms of reducing residual inter-story drifts and damage under earthquake loading, while still maintaining the elastic characteristics associated with FRP.

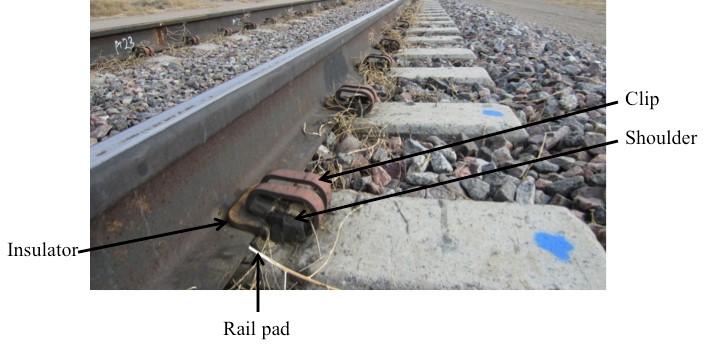

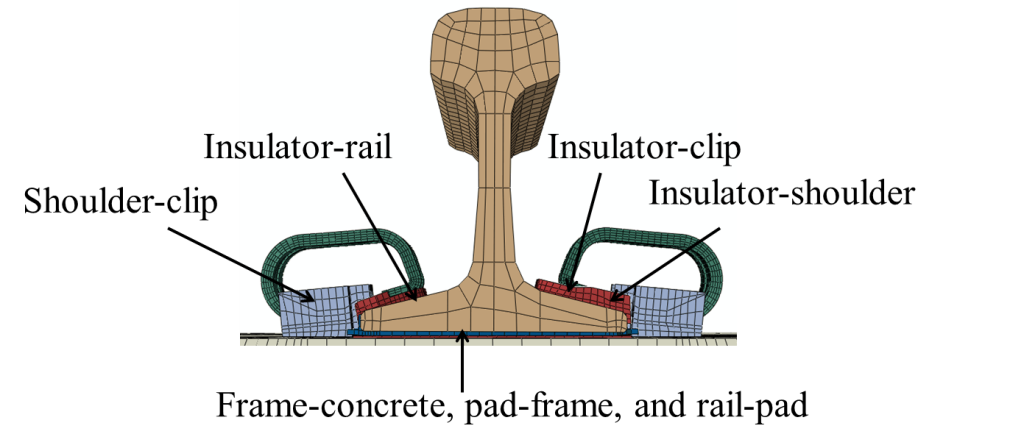

- Improved Concrete Crossties and Fastening Systems for US High Speed Rail and Joint Passenger/Freight Corridors

- Description: The objective of this research is to investigate the performance of concrete crosstie and fastening system under vertical and lateral wheel load using finite element analysis, and explore possible improvement for current track design standard. The damage of fastening system is one of the most prevalent failure causes for concrete crosstie track, however the current AREMA design standard only includes evaluative tests for the fastening system, rather than a mechanistic design approach. To improve the current design approach, the vertical and lateral load path through the track structure and the component demand within the concrete crosstie and fastening system should be further investigated. In addition, to facilitate the application of the knowledge related to the load path through the concrete crosstie and fastening system, mechanistic models should be developed so that engineers could easily estimate the distribution of wheel load.